Method for rapidly determining content of toluene insoluble substances in heavy oil

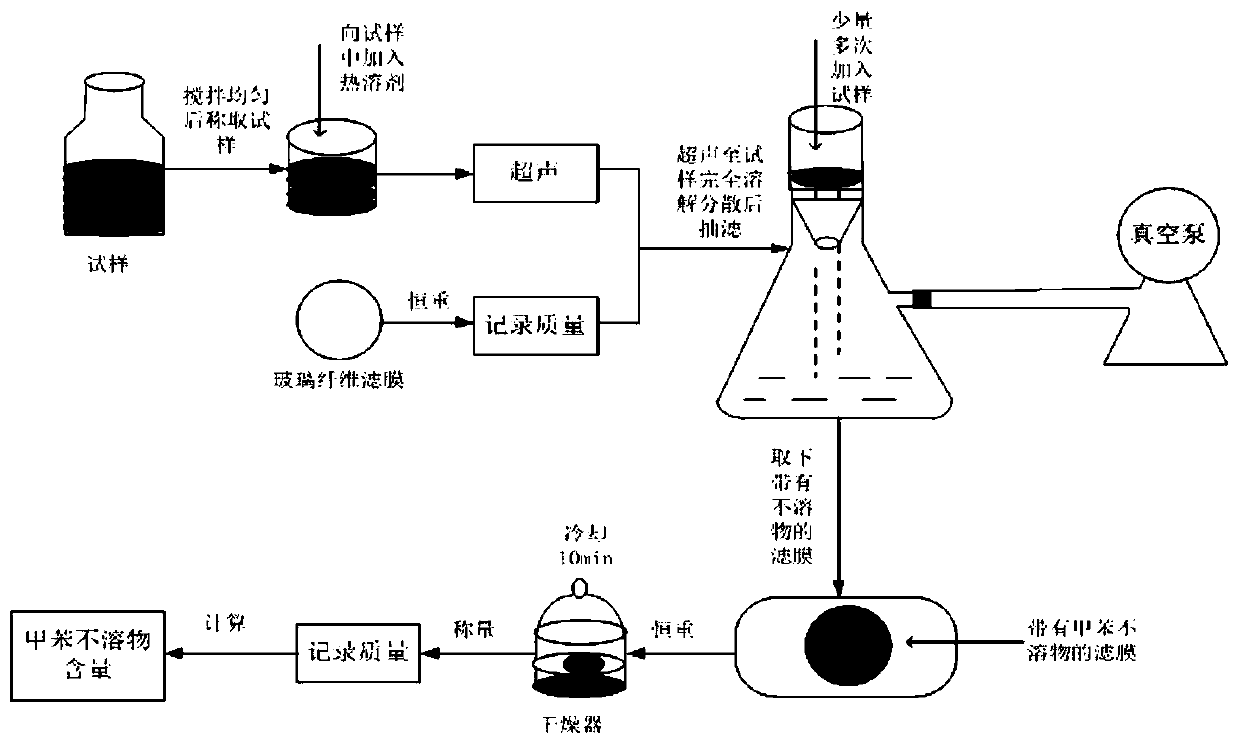

A technology for rapid determination of toluene insoluble matter, applied in the direction of material absorption weighing, test sample preparation, etc., can solve the problems of poor analysis data stability and long sample test cycle, so as to achieve smooth washing process and true and reliable measurement results , to solve the effect of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

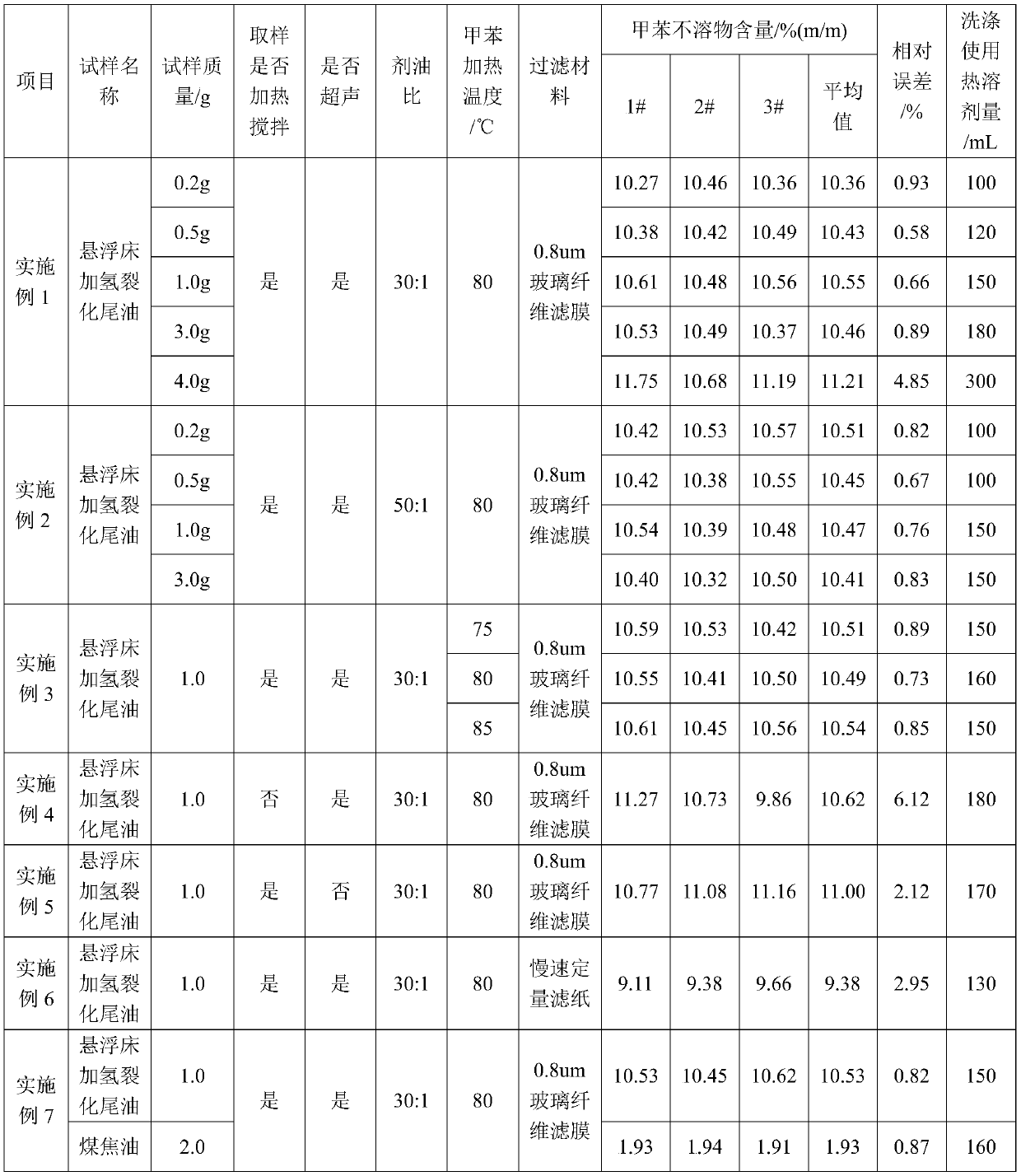

Embodiment 1

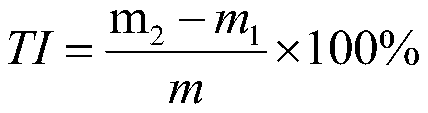

[0049] Select a sample suspension bed hydrocracking tail oil with poor fluidity at room temperature, keep the temperature at 80°C and stir well, weigh 0.2g, 0.5g, 1.0g, 3.0g, 4.0g Put a series of samples in a beaker, add hot toluene according to the ratio of solvent to oil (volume of toluene: sample mass) of 30:1, after ultrasonication for 20 minutes, filter under reduced pressure through a 0.8um glass fiber filter membrane, and measure the toluene insoluble matter content.

[0050] Each group of tests was measured in parallel three times, and the measured results are shown in Table 1, and the test data required for calculating the toluene insoluble content by the formula are shown in Table 2. It is known from the measurement results that when the sample weight is 4.0g, the content of toluene insoluble matter is obviously high, the relative error is large, and the amount of hot solvent used for washing increases significantly; when the sample weight is 0.2g-3.0g, the content o...

Embodiment 2

[0052] Select the suspension bed hydrocracking tail oil of the sample in Example 1, keep the constant temperature at 80°C and fully stir evenly, weigh a series of samples with a mass of 0.2g, 0.5g, 1.0g, and 3.0g in a beaker, According to the ratio of agent to oil (volume of toluene: mass of sample) of 50:1, add hot toluene and sonicate for 20 minutes, then filter under reduced pressure through a 0.8um glass fiber filter membrane, and measure the content of toluene insolubles.

[0053] Each group of tests was measured in parallel three times, and the measured results are shown in Table 1, and the test data required for calculating the toluene insoluble content by the formula are shown in Table 2. Known by each group of toluene insoluble matter content measurement results, when the sample weight is 0.2g-3.0g, the toluene insoluble matter content range is 10.41%-10.51%, and the agent oil ratio in embodiment 1 is 30:1 and records toluene The content of insoluble matter is close, ...

Embodiment 3

[0055] Select the suspension bed hydrocracking tail oil of the sample in Example 1, keep the constant temperature at 80°C and fully stir evenly, weigh three groups of samples with a mass of 1.0g in a 100mL beaker, according to the solvent-oil ratio (toluene volume: test (sample mass) was 30:1, adding hot toluene at 75°C, hot toluene at 80°C, and hot toluene at 85°C. After ultrasonication for 20 minutes, filter under reduced pressure through a 0.8um glass fiber filter membrane to measure the content of toluene insolubles.

[0056] Each group of tests was measured in parallel three times, and the measured results are shown in Table 1, and the test data required for calculating the toluene insoluble content by the formula are shown in Table 2. It is known from the measurement results that the contents of toluene insolubles at a temperature of 75° C. to 85° C. are basically the same when the toluene is heated, and the relative errors are all less than 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com