Parameterization design method of three-dimensional guide pipe welding clamp

A parametric design and welding fixture technology, applied in design optimization/simulation, calculation, image data processing, etc., can solve the problems of high design cost, low efficiency, insufficient systematization and standardization, etc., to reduce operating time and improve design Efficiency, convenience and quick effect of tooling design tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

[0021] A parametric design method of three-dimensional conduit welding fixture, which is completed based on UG NX7.5 software, with the help of the expression function of UGNX7.5, specifically includes the following steps:

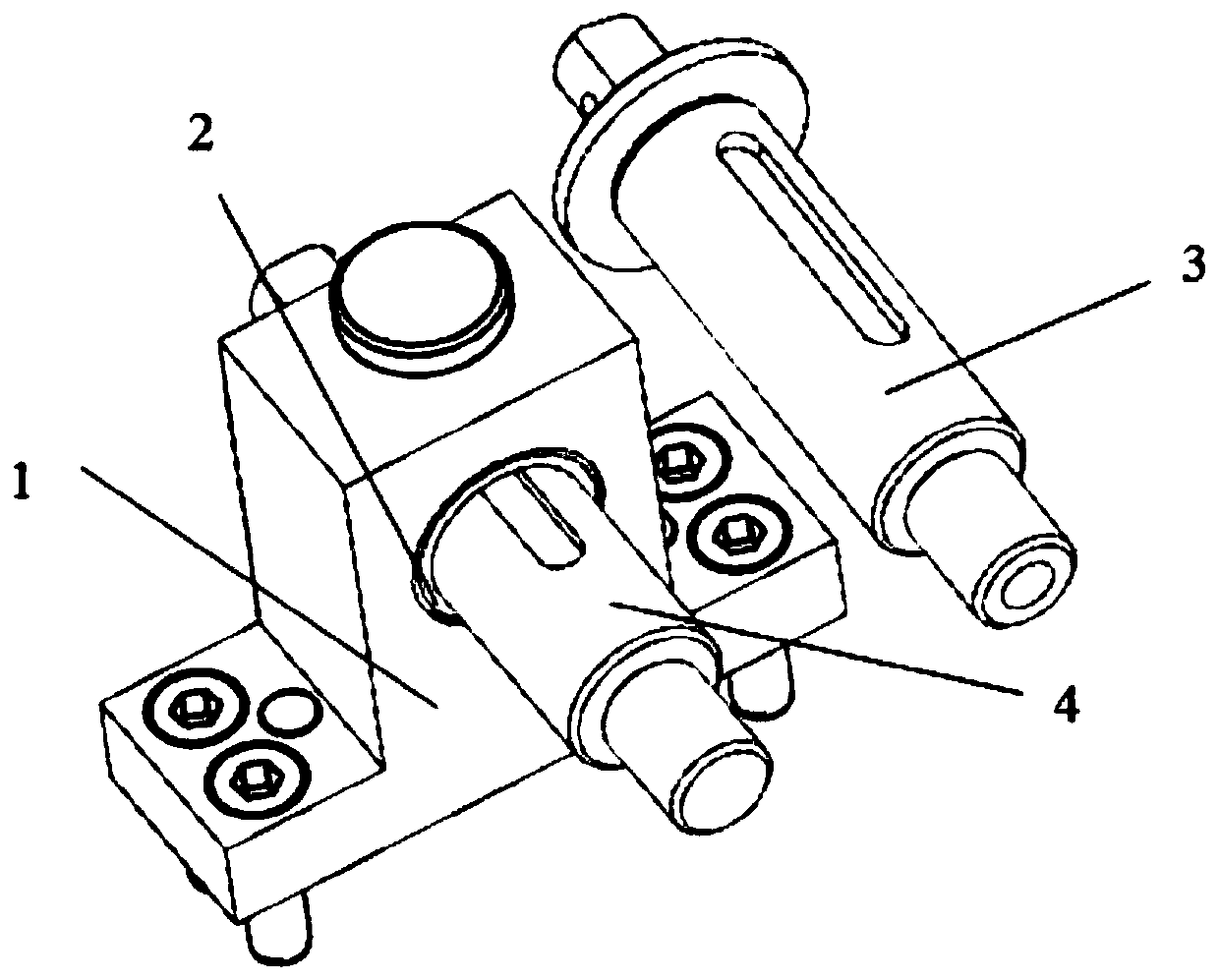

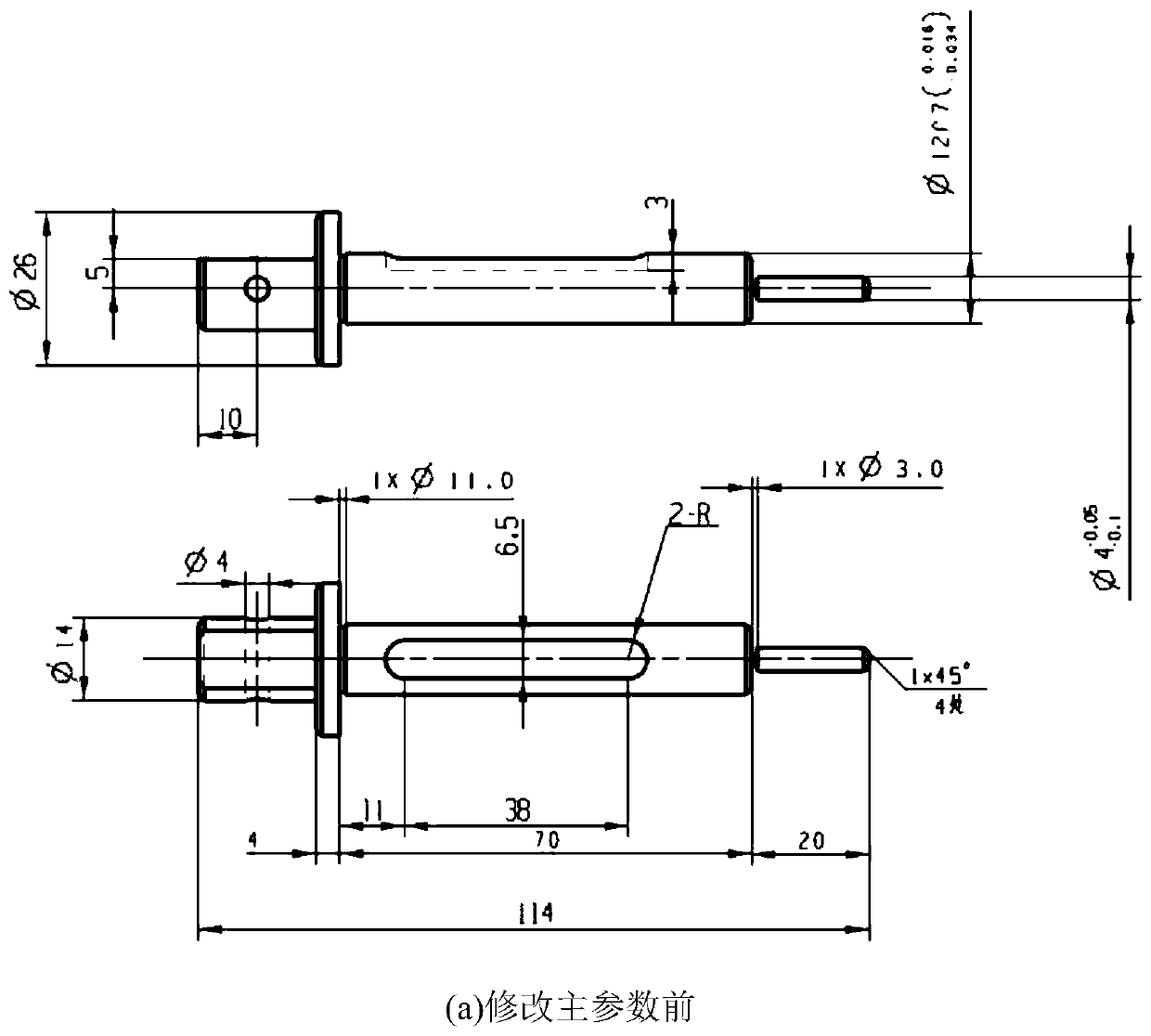

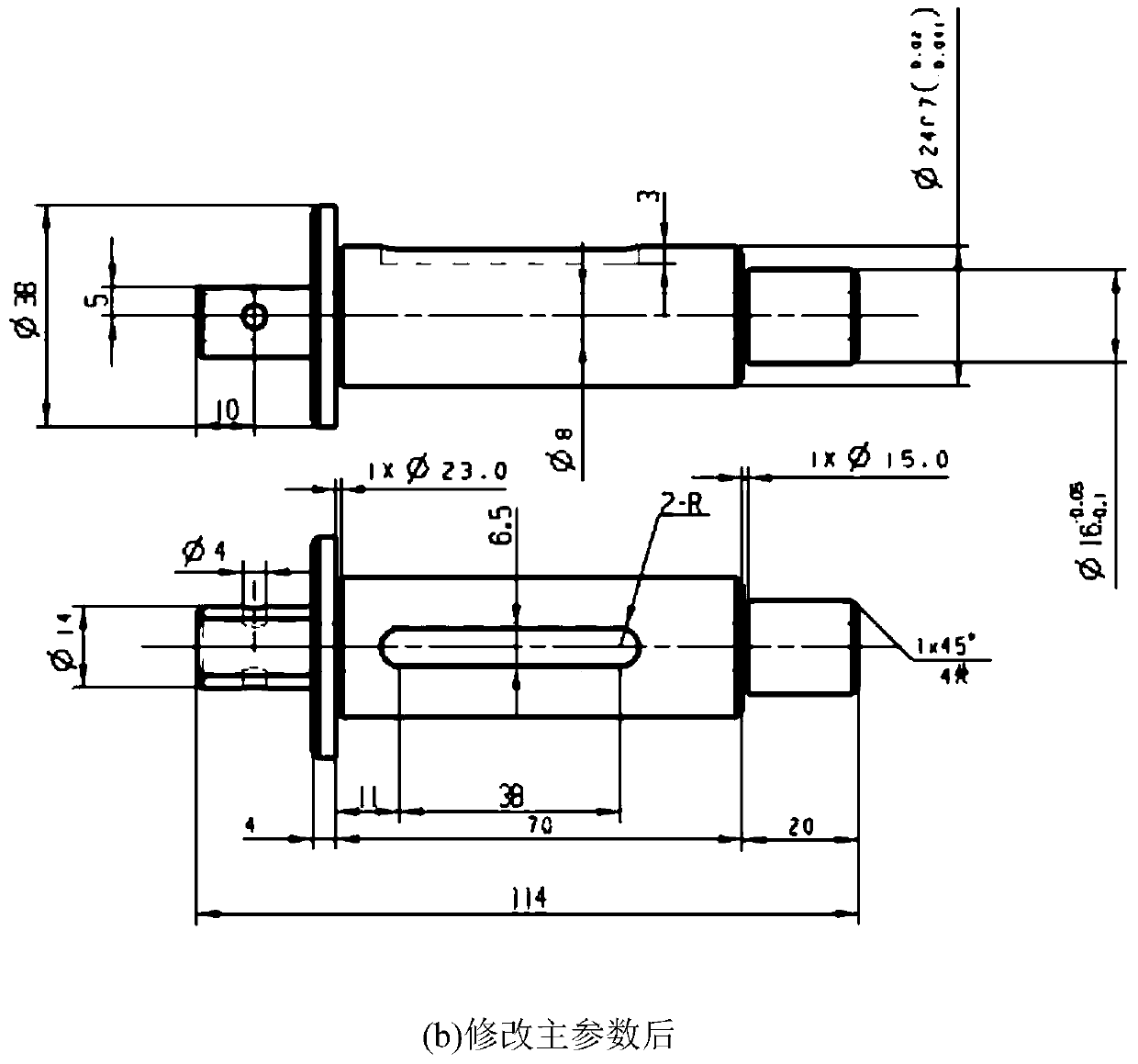

[0022] Step 1: Click the button on the personal resource board to start the tooling module containing the standard part family: call the parametric model of the typical part of the standard part, generate a typical parametric tooling standard part model, and start the tooling standard part menu with parametric drive resource bars;

[0023] Step 2: Select a typical part tooling module to create a master unit module tooling: select different standard parts in the tooling module containing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com