A kind of cable stripping system and material sorting method

A cable and cable management technology, applied in the field of cable stripping system and material management, can solve the problems of damage to the internal circuit, the incision is not beautiful, damage to the internal circuit of the cable, etc., to avoid the offset of the cutting position, and the structural design Reasonable and ingenious to ensure the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

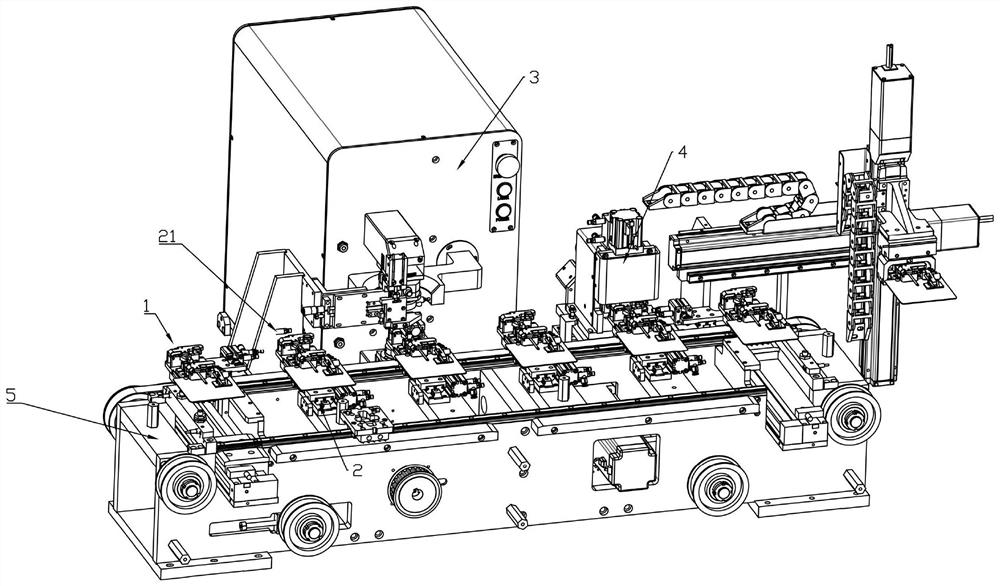

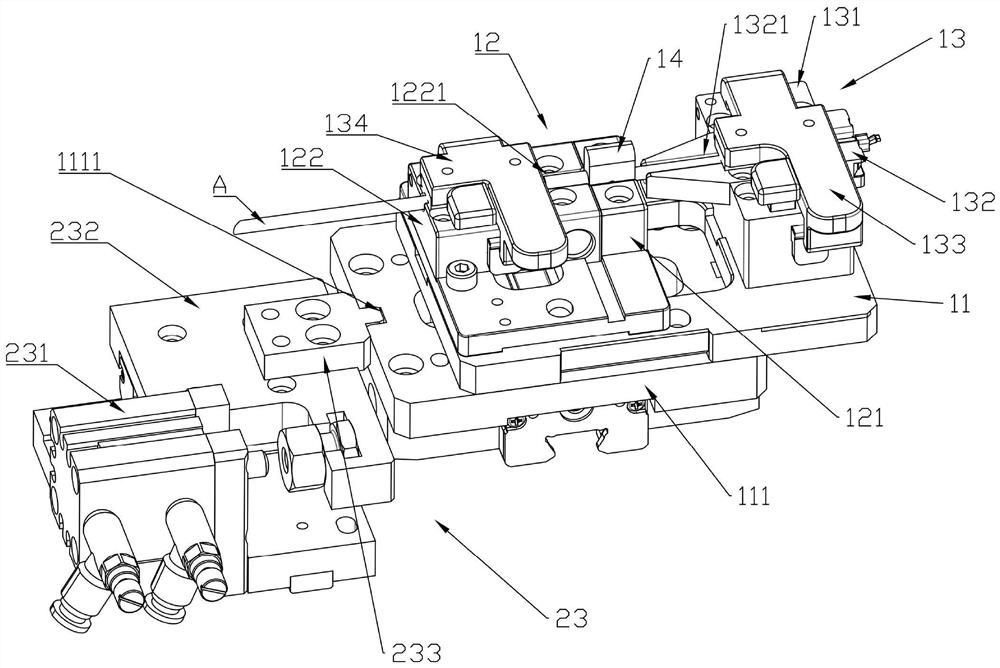

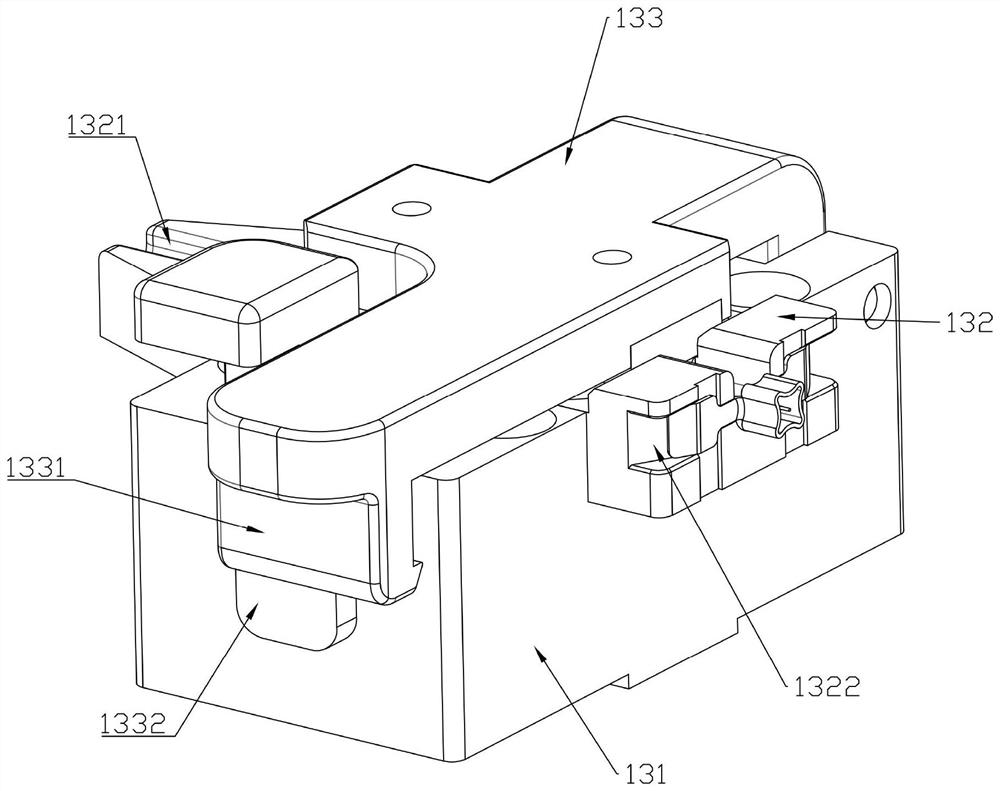

[0026] Examples, see Figure 1 to Figure 6 A cable stripping system provided in this embodiment includes: a cable management tool 1, a cable management device 2 arranged in sequence, a double-headed laser cutting device 3, a stripping device 4, and a cable management tool 1 that drives the wire The wire device 2, the double-head laser cutting device 3, and the jig conveying line 5 that moves between the peeling device 4; the wire management jig 1 includes a base 11 and a corresponding auxiliary wire management part 12 for adjusting the first extension of the wire. The amount of thread head positioning part 13, the auxiliary thread management part 12 is fixedly connected with the base 11, and the thread head positioning part 13 is movable and installed on the base 11 in a longitudinally movable manner; A cable bending eliminating assembly 14 is clamped on the wire portion 12 .

[0027] Specifically, through the cable management device 2, the double-head laser cutting device 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com