Seeding machine

A planter and rack technology, which is applied to fertilizers, planting equipment, planting methods, applications, etc., can solve the problems of complex structure of planters and poor passability of tools and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

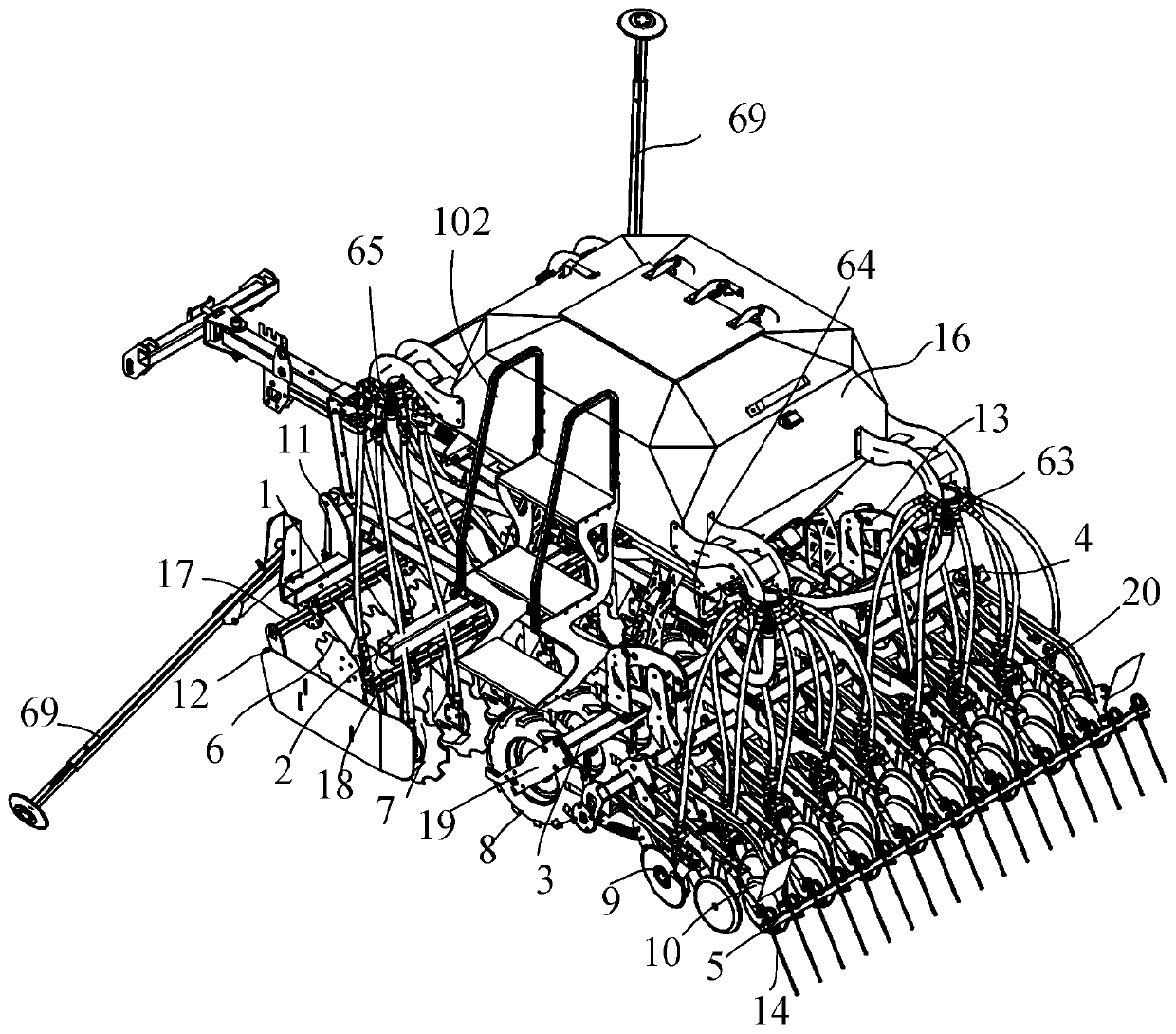

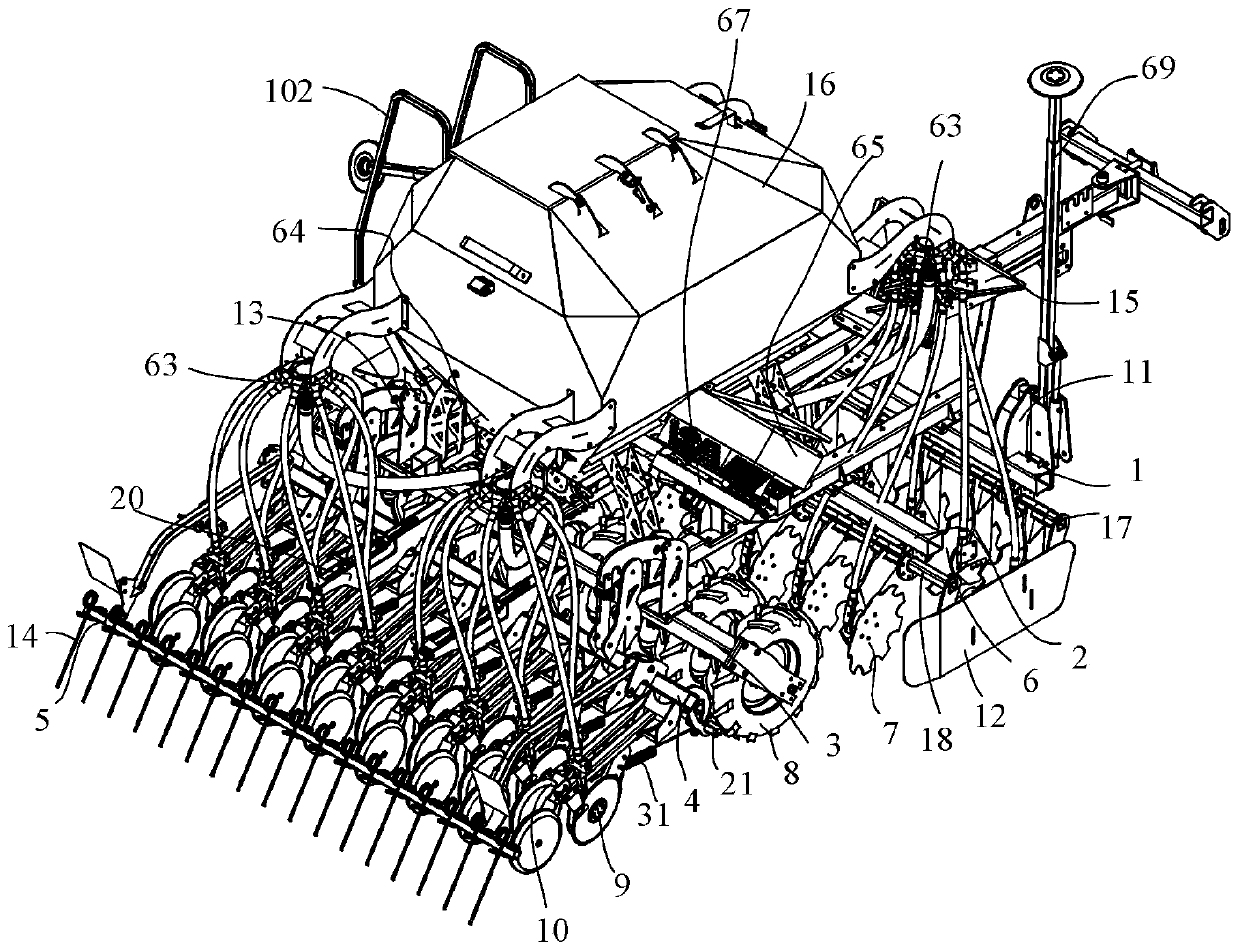

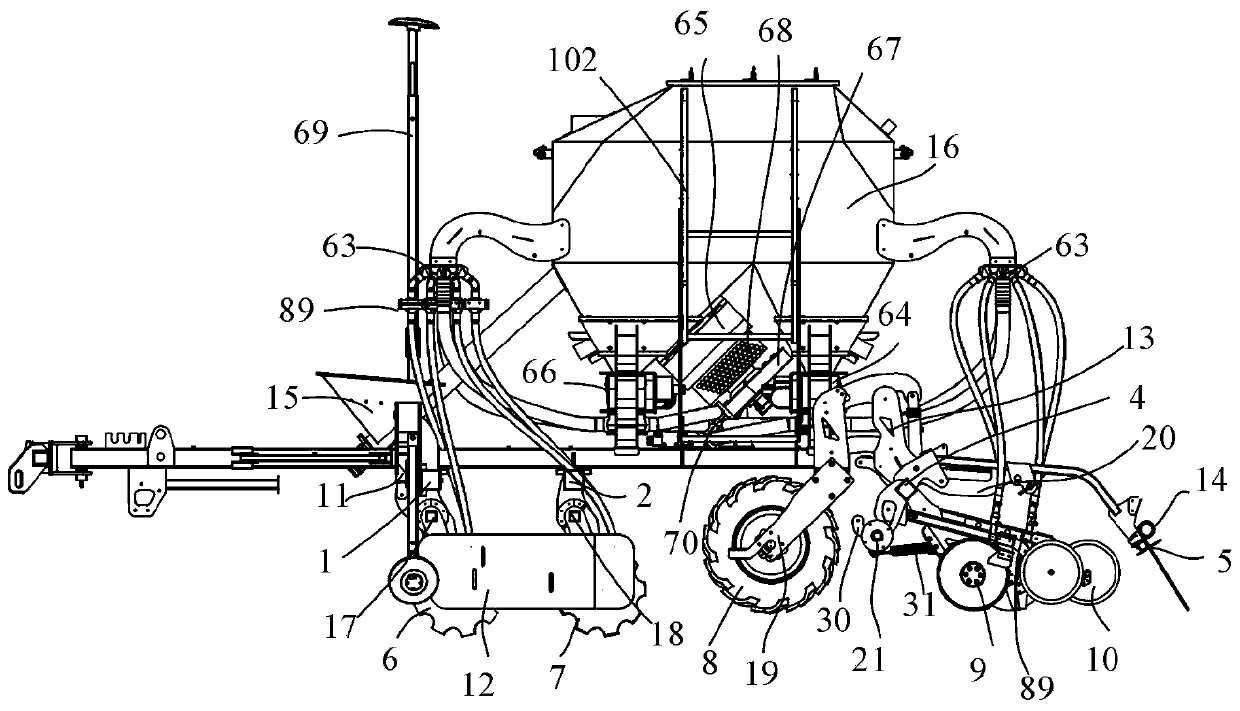

[0037] Such as Figure 1 to Figure 5 As shown, a planter in this embodiment includes a frame, a fertilizing monomer assembly, a walking suppression assembly, a seeding monomer assembly, a soil covering device, a selective material lifting mechanism 15, a seed fertilizer box 16, and a planter. Fertilizer discharge system and liner 69; the front end of the frame is provided with a traction frame, and the rear side of the frame is located at the traction frame and is successively provided with a fertilization monomer assembly, a walking suppression assembly, a seeding monomer assembly and a soil covering device. The two sides of the front end of the frame are respectively provided with markers 69; the top of the frame is fixed with a kind of fertilizer box 16, and one end of the selective material lifting mechanism 15 is fixed on the front bottom of the kind of fertilizer box 16, and the other end extends into the kind of fertilizer box 16, the selective material lifting mechanis...

Embodiment 2

[0040] Figure 1 to Figure 17 As shown, a planter in this embodiment includes all the technical features in Embodiment 1. In addition, the fertilization unit assembly includes a first beam 1, a second beam 2, a plurality of first fertilization units Body 6, a plurality of second fertilization monomers 7, fertilization pressure regulating device 11 and linkage 12; the walking suppression assembly includes a third crossbeam 3, a plurality of walking suppression wheels 8 and wheel arms 19; the sowing monomer assembly includes The fourth crossbeam 4, a plurality of first sowing units 9, a plurality of second sowing units 10 and a planting pressure regulating device 13; the soil covering device includes the fifth crossbeam 5 and a plurality of spring teeth 14; the first crossbeam 1, the second The beam 2, the third beam 3, the fourth beam 4 and the fifth beam 5 are arranged in parallel at intervals from front to back. The first beam 1, the second beam 2 and the third beam 3 are all...

Embodiment 3

[0043] Figure 1 to Figure 17 As shown, a planter in this embodiment includes all the technical features in Embodiment 2. In addition, the fertilization unit assembly also includes a shock absorber 41, a first rotating beam 17 and a second rotating beam 18. The fertilization pressure regulating device 11 includes a support plate 22, a fertilization hydraulic cylinder 23 and a fertilization connection ear 24; the shock absorber 41, the first rotating beam 17 and the second rotating beam 18 are square steel pipe structures, and the first fertilizing monomer 6 The shock absorber 41 is connected to the first rotating beam 17 through the shock absorber 41. The shock absorber 41 on the first fertilization unit 6 is sleeved on the first rotate beam 17. The second fertilization unit 7 is connected to the first rotating beam 17 through the shock absorber 41. On the two rotating crossbeams 18, the shock absorber 41 on the second fertilization monomer 7 is sleeved on the second rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com