Orange peeling device

A peeling device and orange peeling technology, which is applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of low efficiency, failure to ensure that the same standard of orange peeling is peeled off, and many defective products. The effect of saving energy, reducing defective products, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

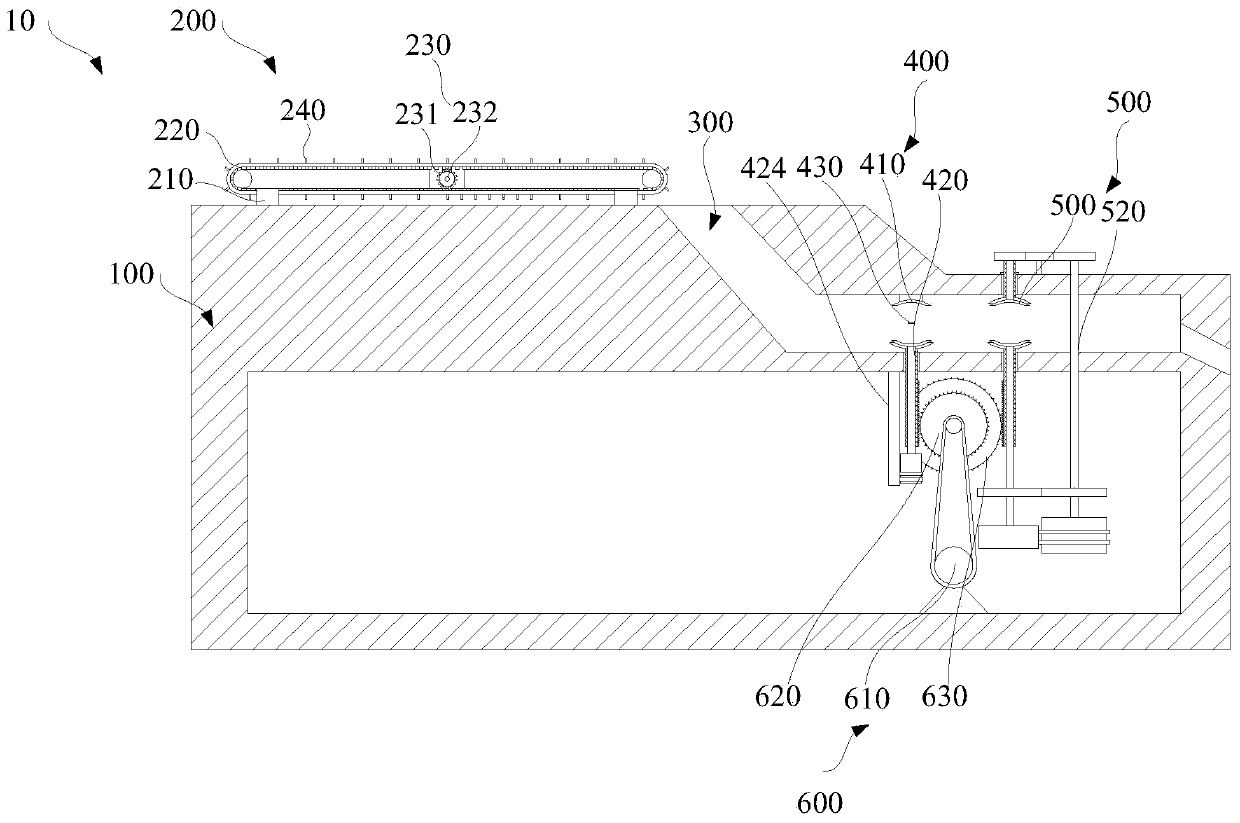

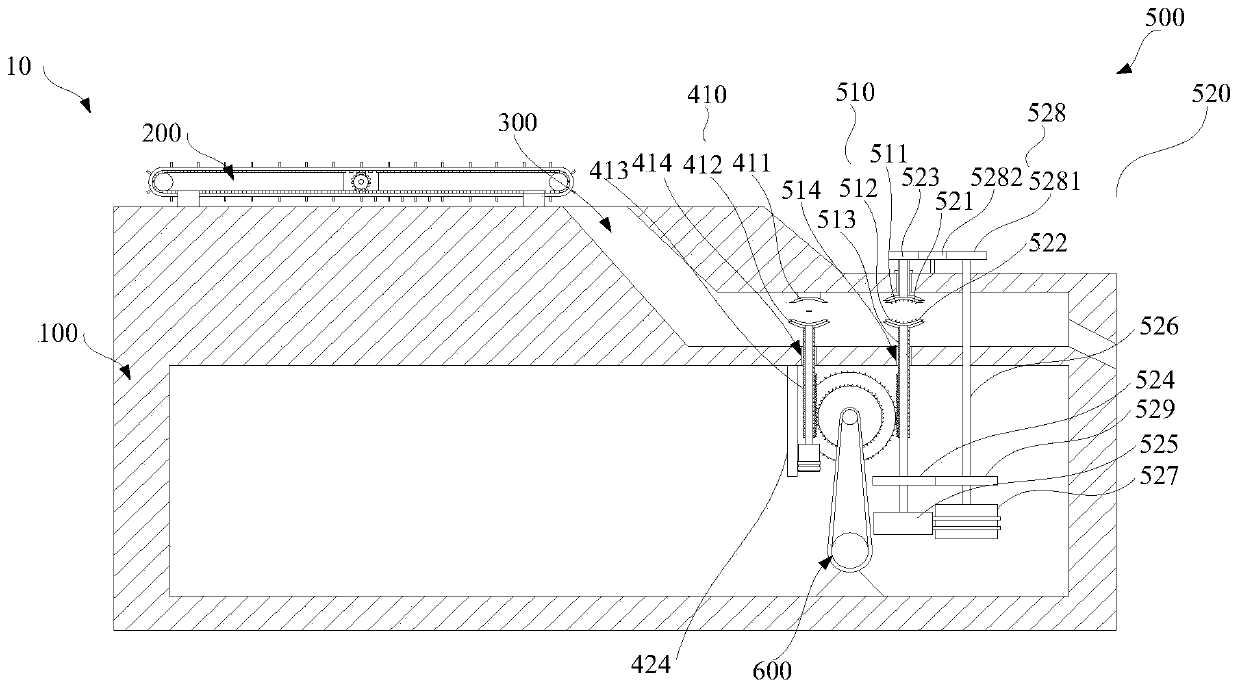

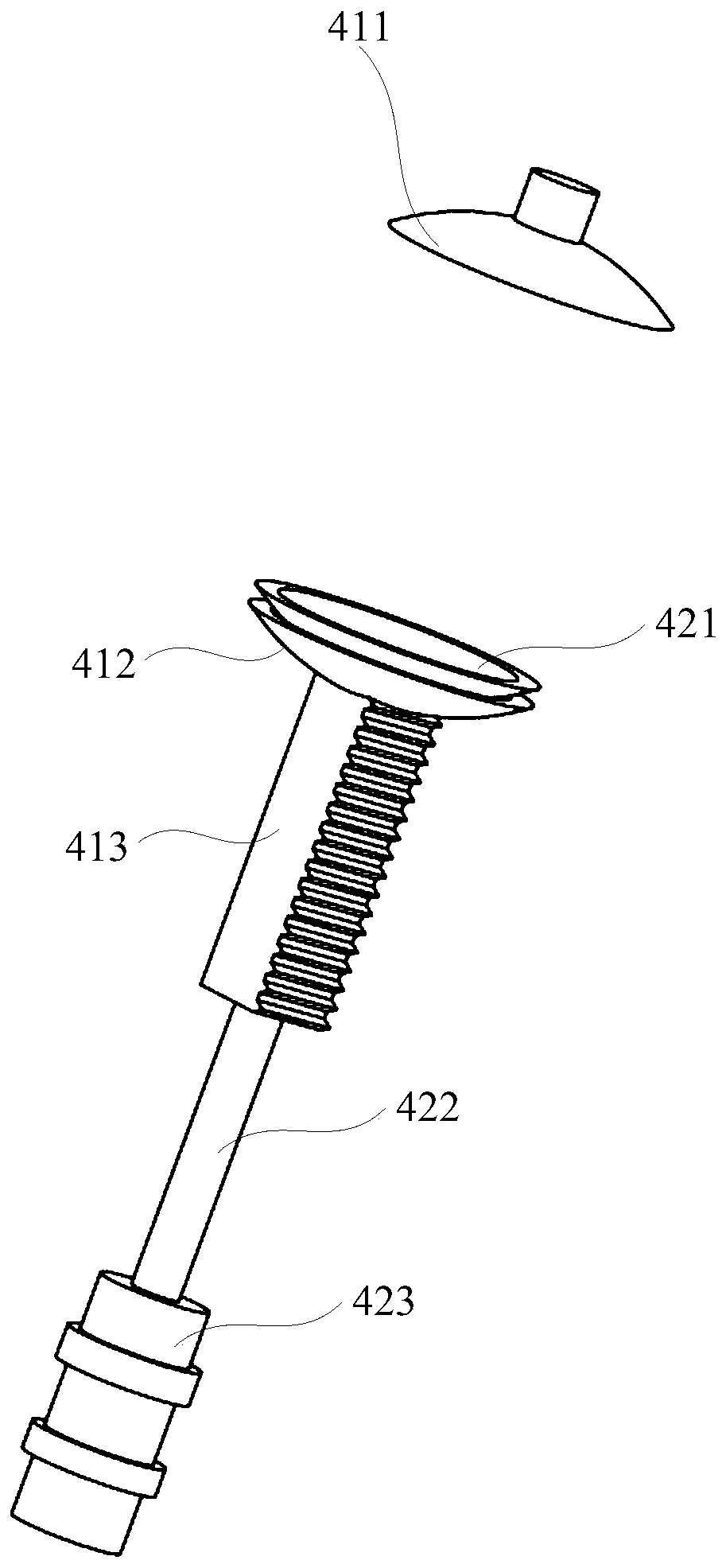

[0026] Such as Figure 1 to Figure 3 Shown, the present embodiment provides a kind of orange peel peeling device 10, comprises frame 100, conveying mechanism 200, processing chamber 300, rotary cutting mechanism 400, peeling mechanism 500 and total drive assembly 600, is used for orange peel from orange Peel off.

[0027] Specifically, the rack 100 is used to support the entire device. The conveying mechanism 200 is arranged at the front end of the frame 100, and the conveying mechanism 200 is used for conveying oranges. The processing chamber 300 is located at the rear end of the conveying mechanism 200 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com