Control method and device of wall breaker, wall breaker and computer-readable storage medium

A control method and a technology of a wall breaker, which are applied in the control of a wall breaker, the field of a wall breaker and computer-readable storage media, can solve the problems of increasing the difficulty of using cooking appliances and the workload of use, and avoid excessive boiling time , Reduce the effect of cooking difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

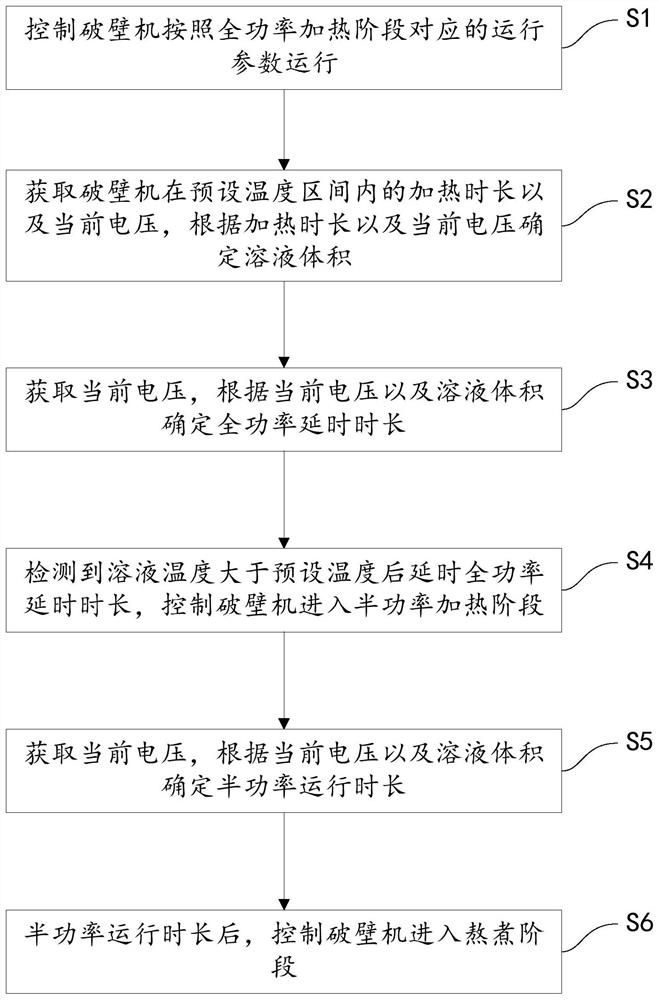

[0044] This embodiment provides a method for controlling a broken wall machine. The cooking process of the broken wall machine includes a full-power heating stage, a half-power heating stage, and a boiling stage, such as figure 1 As shown, the method includes the following steps:

[0045] Step S1, controlling the wall breaking machine to operate according to the corresponding operating parameters in the full power heating stage;

[0046] Step S2, obtaining the heating time and current voltage of the wall breaker in the preset temperature range, and determining the volume of the solution according to the heating time and current voltage;

[0047] Step S3, obtain the current voltage, and determine the full power delay time according to the current voltage and the volume of the solution;

[0048] Step S4, after detecting that the temperature of the solution is higher than the preset temperature, delay the full power delay time, and control the breaking machine to enter the half ...

Embodiment 2

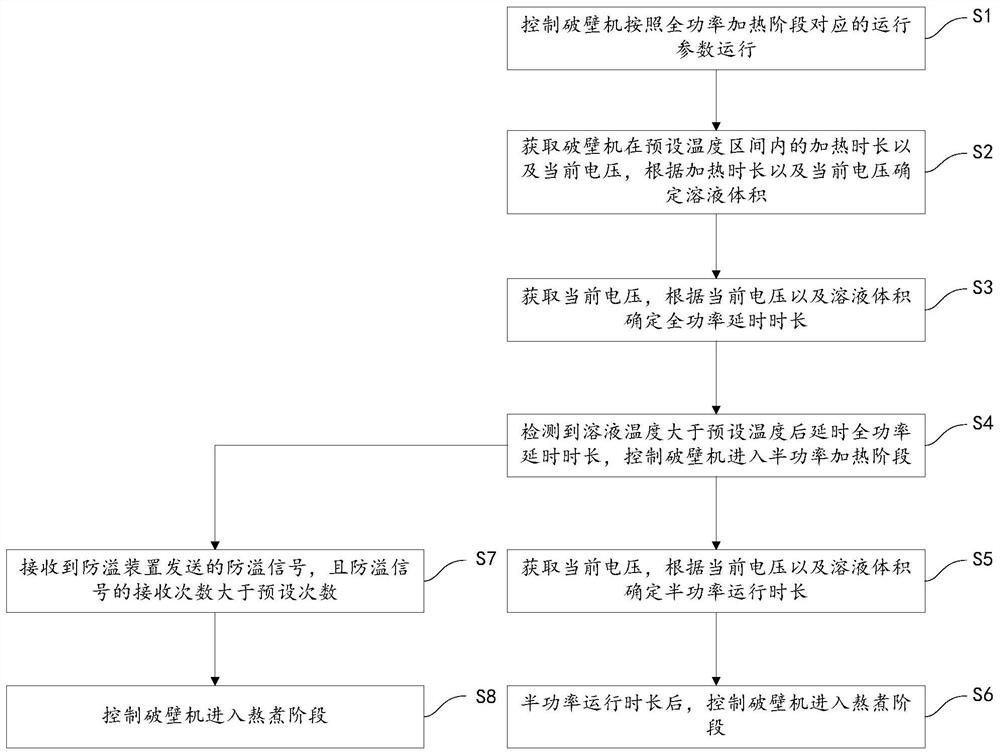

[0056] This embodiment provides a control method for a broken wall machine. The cup lid of the broken wall machine is provided with an overflow prevention device. After step S4 of controlling the broken machine to enter the half-power heating stage, as follows figure 2 As shown, the method also includes:

[0057] Step S7, when the anti-overflow signal sent by the anti-overflow device is received, and the number of times the anti-overflow signal is received is greater than the preset number of times, step S8 is executed;

[0058] Step S8, controlling the broken wall machine to enter the boiling stage.

[0059] In this embodiment, the anti-overflow device includes but is not limited to anti-overflow electrodes. During the half-power heating stage, the anti-overflow device detects anti-overflow signals in real time. Once the solution or foam in the wall breaker rises to the cup lid, the anti-overflow signal is recorded once. Taking the preset number of times as 3 times as an ex...

Embodiment 3

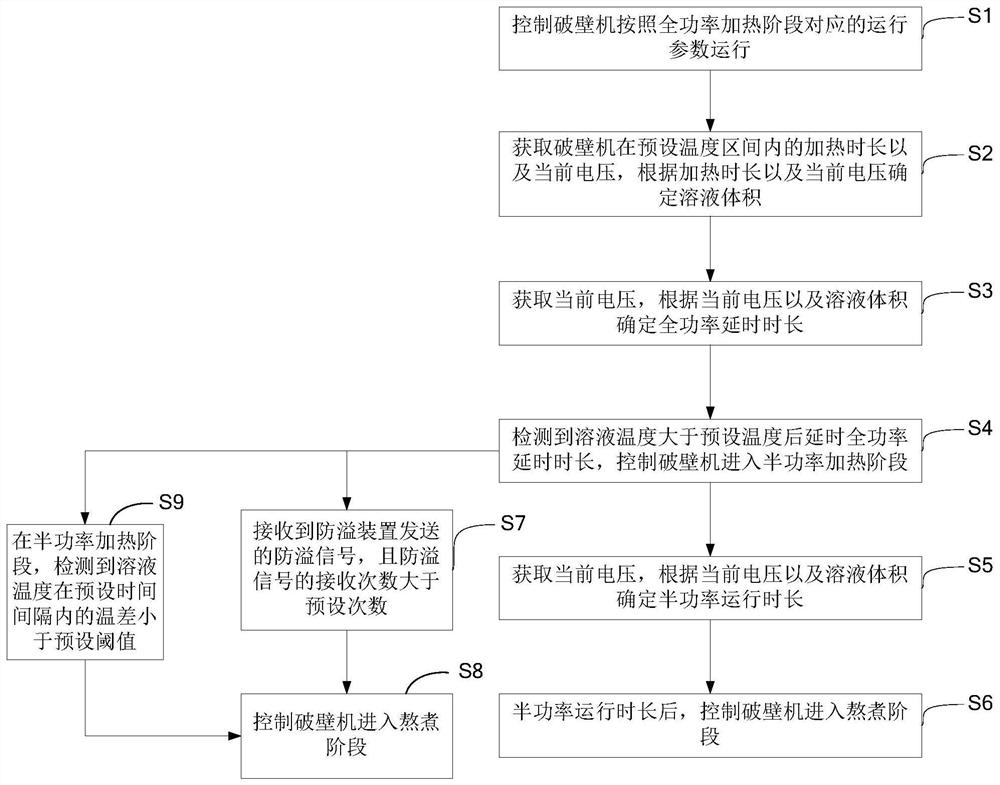

[0061] This embodiment provides a method for controlling a broken wall machine. On the basis of Embodiment 1, after step S4 of controlling the broken wall machine to enter the half-power heating stage, as follows image 3 As shown, the method also includes:

[0062] Step S9. In the half-power heating stage, when it is detected that the temperature difference of the solution temperature within the preset time interval is less than the preset threshold, step S8 is executed;

[0063] Step S8, controlling the broken wall machine to enter the boiling stage.

[0064] Taking the preset time interval of 1 minute and the preset threshold of 0.5°C as an example, in the half-power heating stage, if the temperature difference of the solution temperature is detected to be 0.1°C within 1 minute, that is, when it is less than the preset threshold of 2°C, the control will break the wall The machine enters the cooking stage.

[0065] In this embodiment, if the temperature difference of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com