A high-efficiency condensation absorption tower

An absorption tower and high-efficiency technology, applied in separation methods, gas treatment, dispersed particle separation, etc., can solve problems such as rising operating costs, and achieve the effects of reducing moisture content, reducing the frequency and amount of water replenishment, and reducing operating costs for desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

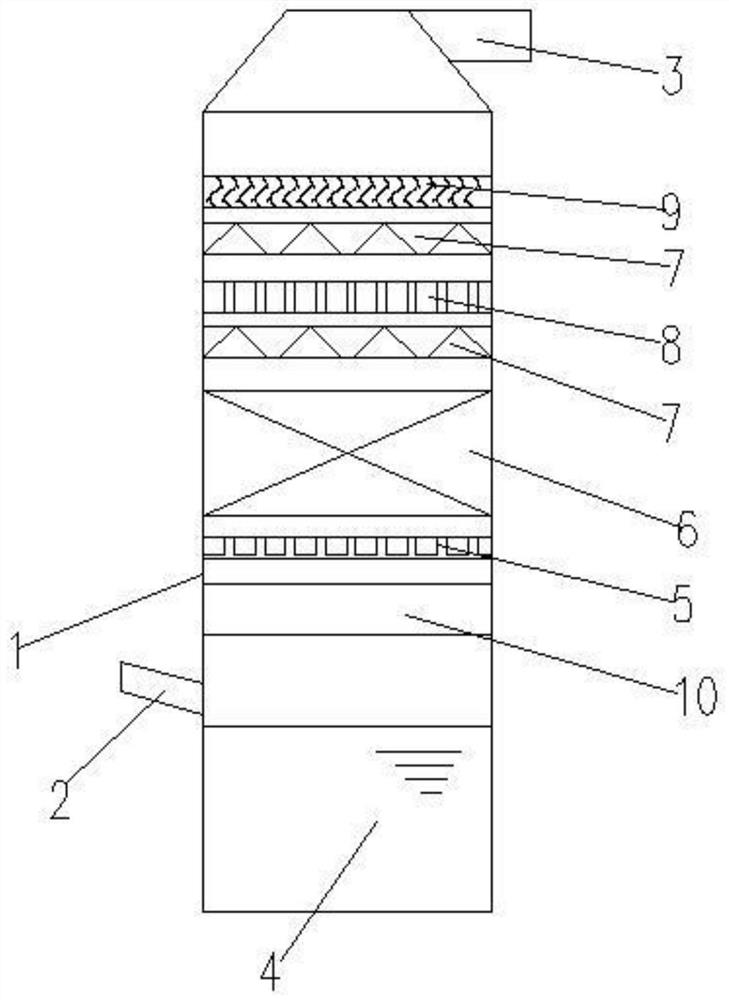

[0035] Attached below Figure 1-19 The embodiments of the present invention are described in detail.

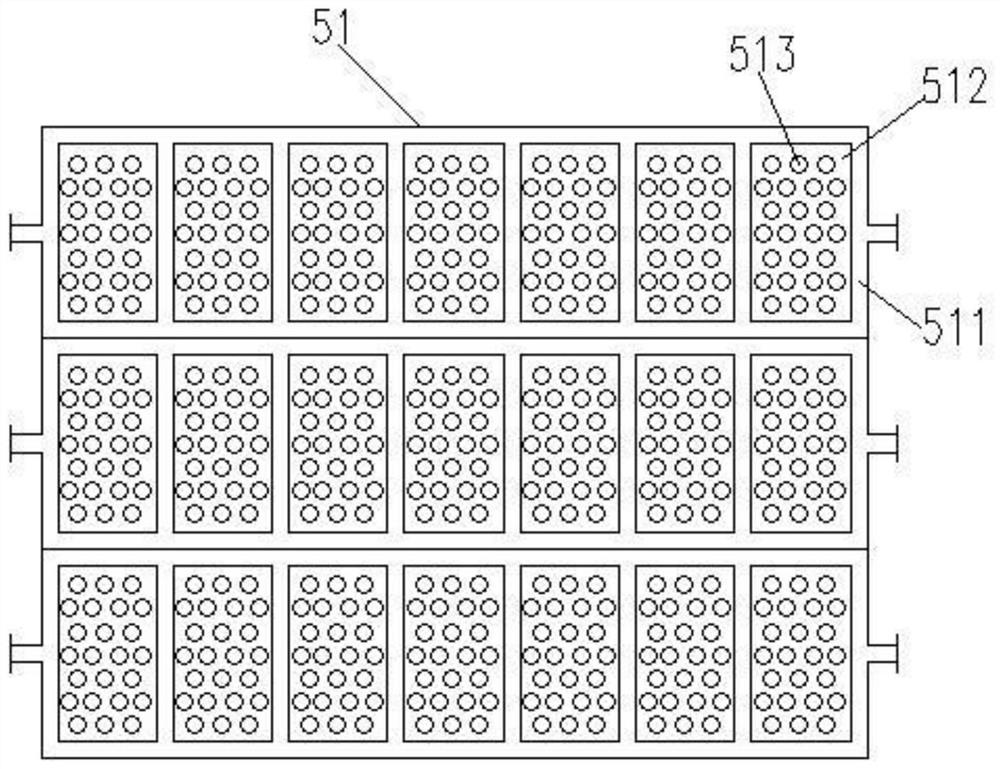

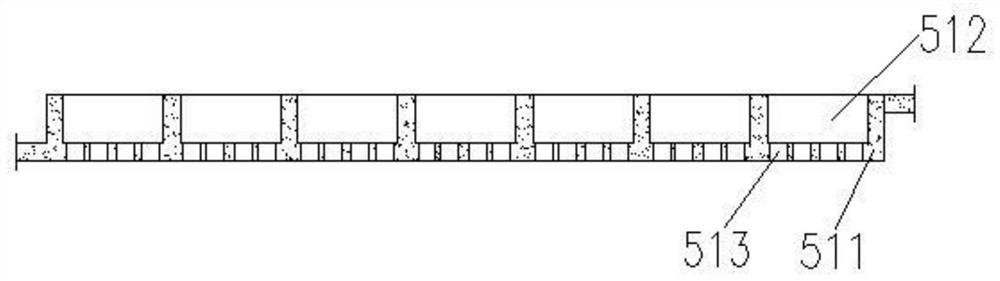

[0036] A high-efficiency condensation absorption tower, comprising a tower body 1, a slurry pool 4 is provided at the inner lower part of the tower body 1, a flue gas inlet pipe 2 is connected to the lower left side of the tower body 1, and the connection between the flue gas inlet pipe 2 and the tower body 1 is as high as At the liquid level of the slurry pool 4, the flue gas inlet pipe 2 is arranged obliquely, and the end of the flue gas inlet pipe 2 connected to the tower body 1 is lower than the other end, and the upper part of the tower body 1 is connected to the flue gas outlet pipe 3, and the inside of the tower body 1 From top to bottom, there are four layers of demisters, spraying area 6, and condensation tray 5. There is a liquid distributor 10 under the condensation tray 5. The height of the condensation tray 5 is higher than that of the flue gas inlet pipe 2. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com