Flotation-gravity combined beneficiation process for Anshan-type hematite

A hematite and Anshan-type technology, which is applied in the field of Anshan-type hematite flotation combined beneficiation process, can solve the problems of frequent ore circulation, difficult production operation, and easy fluctuation of production indicators, and achieves reduced tailings grade and qualified The effect of increasing the rate and reducing the amount of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

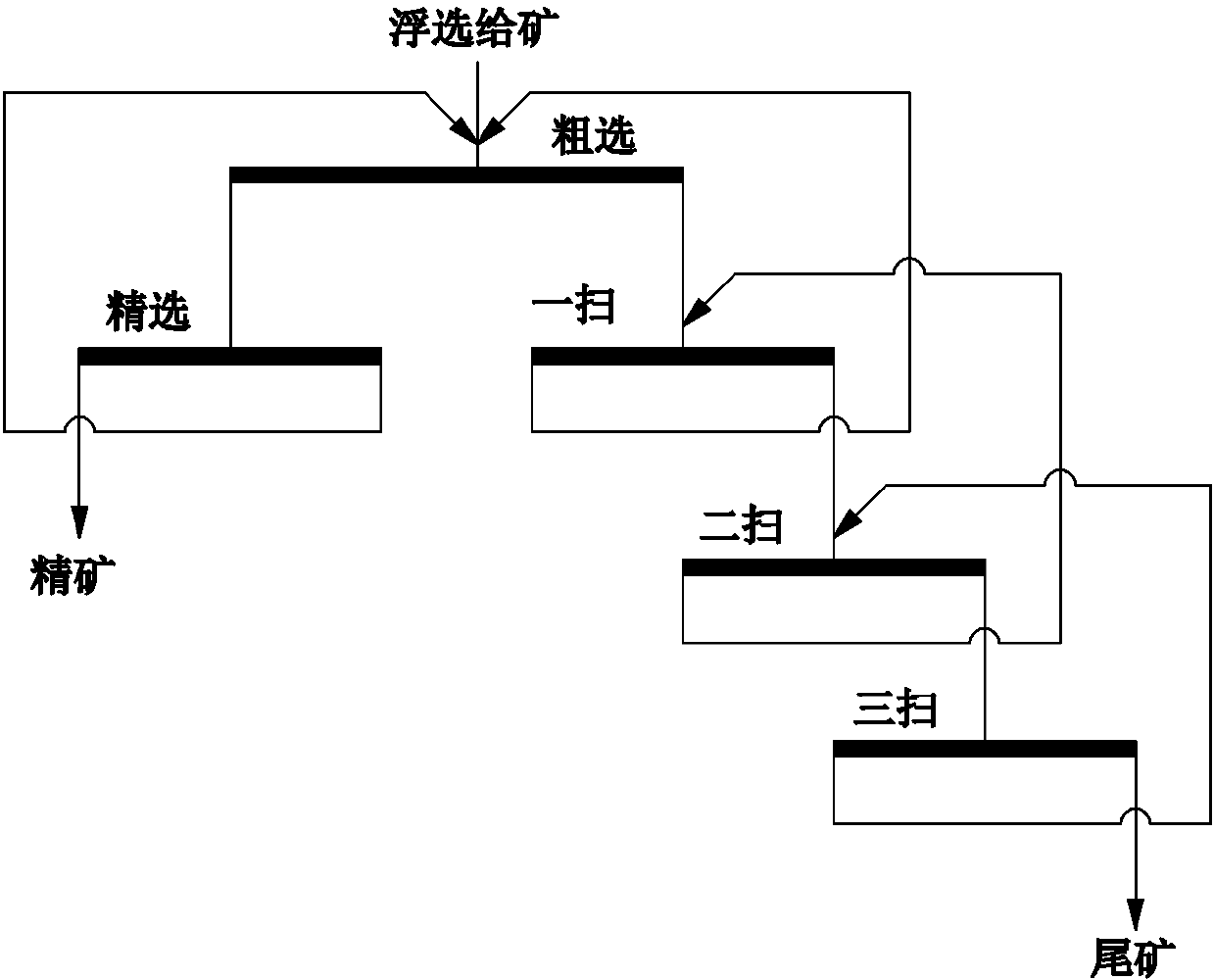

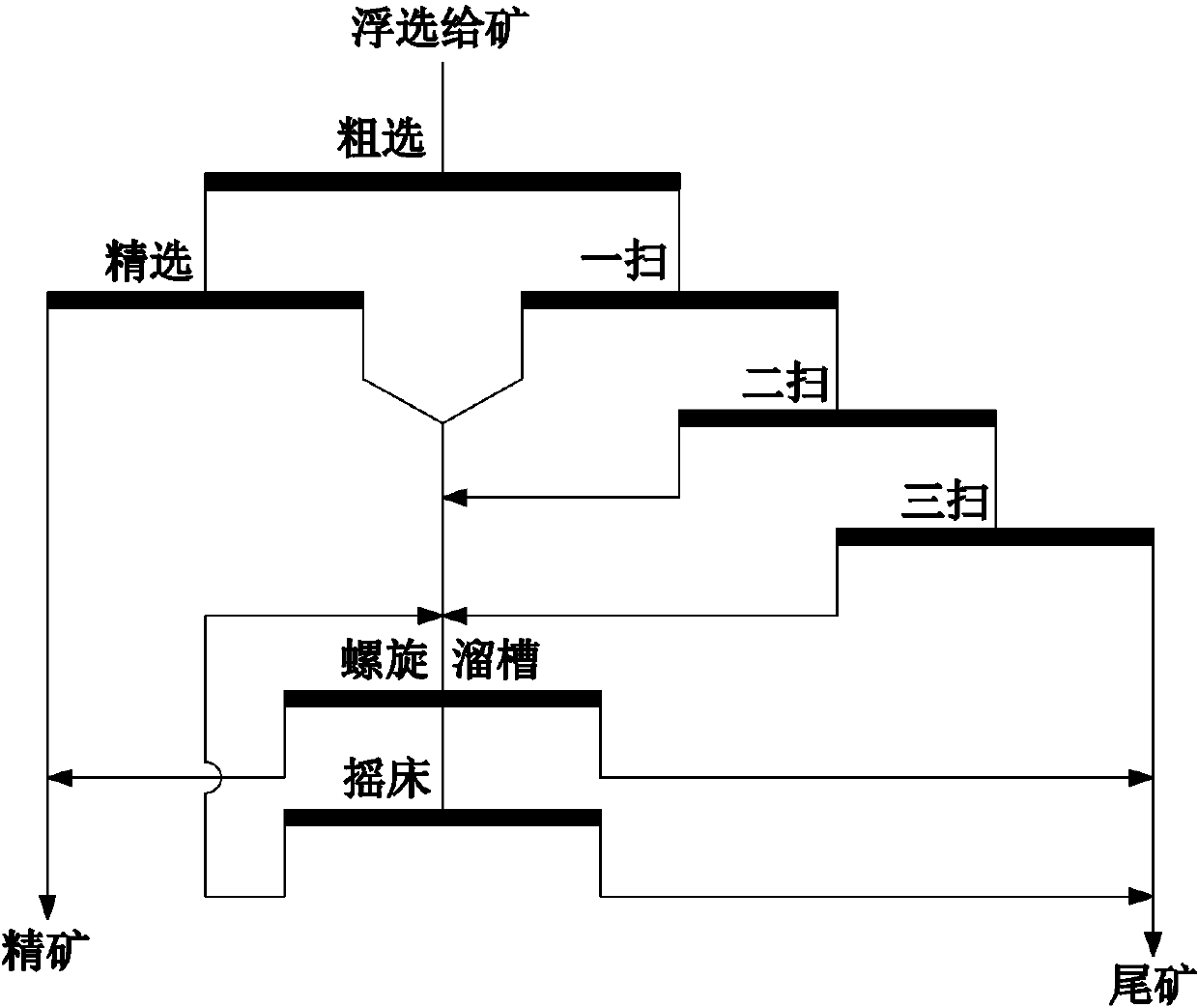

[0021] The ore sample used in the test of this embodiment is the Anshan type hematite flotation feed used in Anqian Concentrator, the -200 mesh content is 85%, and the iron grade of the feed is 45.42%. figure 2 Shown technique of the present invention is sorted out, carries out according to the following steps:

[0022] (1) Flotation operation

[0023] The flotation operation consists of one stage of roughing, one stage of fine selection and three stages of sweeping:

[0024] The above-mentioned flotation feed ore of Anqian Concentration Plant is fed into the first stage of roughing, the grade of the first stage of rougher concentrate is 55.89%, and the grade of the first stage of rougher tailings is 35.31%; the first stage of rougher concentrate is fed into the first stage of concentration operation to obtain The grade is 65.52%. The first stage of concentrated ore and the first stage of concentrated tailings; The third-stage scavenging tailings with a grade of 16.33%; the...

Embodiment 2

[0030] The sorting process is the same as embodiment 1, and the difference is that the ore grade and granularity are different, so the sorting index is different, as follows:

[0031] (1) Flotation feed ore -200 mesh content 95%, iron grade 49.88%;

[0032] (2) The grade of the first roughing concentrate is 59.42%, the grade of the first roughing tailings is 34.91%, and the grade of the first roughing concentrate is 67.84%;

[0033] (3) The tailings grade of the third-stage sweeping process is 15.35%. The ore grade in flotation operation is 44.97%;

[0034] (4) The concentrate grade of the spiral chute is 66.39%, the grade of medium ore in the spiral chute is 34.39%, and the grade of tailings in the spiral chute is 19.20%;

[0035] (5) Shaker concentrate grade is 44.42%, shaker tailings grade is 24.52%;

[0036] (6) The final concentrate grade is 67.34%, and the final tailings grade is 19.59%.

Embodiment 3

[0038] The sorting process is the same as embodiment 1, and the difference is that the ore grade and granularity are different, so the sorting index is different, as follows:

[0039] (1) Flotation feed ore -200 mesh content 90%, iron grade 48.36%;

[0040] (2) The grade of the first stage of roughing concentrate is 58.65%, the grade of the first stage of roughing tailings is 34.02%, and the grade of the first stage of refined concentrate is 66.52%;

[0041] (3) The tailings grade of the third-stage sweeping is 18.27%, and the ore grade of the flotation operation is 43.45%;

[0042] (4) The concentrate grade in the spiral chute is 65.44%, the grade in the spiral chute is 33.83%, and the grade of tailings in the spiral chute is 18.01%;

[0043] (5) The shaker concentrate grade is 43.50%, and the shaker tailings grade is 23.83%;

[0044] (6) The final concentrate grade is 66.51%, and the final tailings grade is 17.27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com