Automatic forging production line

A technology of automatic production line and driven wheel, which is used in manufacturing tools, forging/pressing/hammer devices, transportation and packaging, etc. It can solve the problem of deviation in the placement of blank bars, manual production efficiency, and inconsistent bar heating temperature. problems, to achieve the effect of improving product quality, high production efficiency, and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

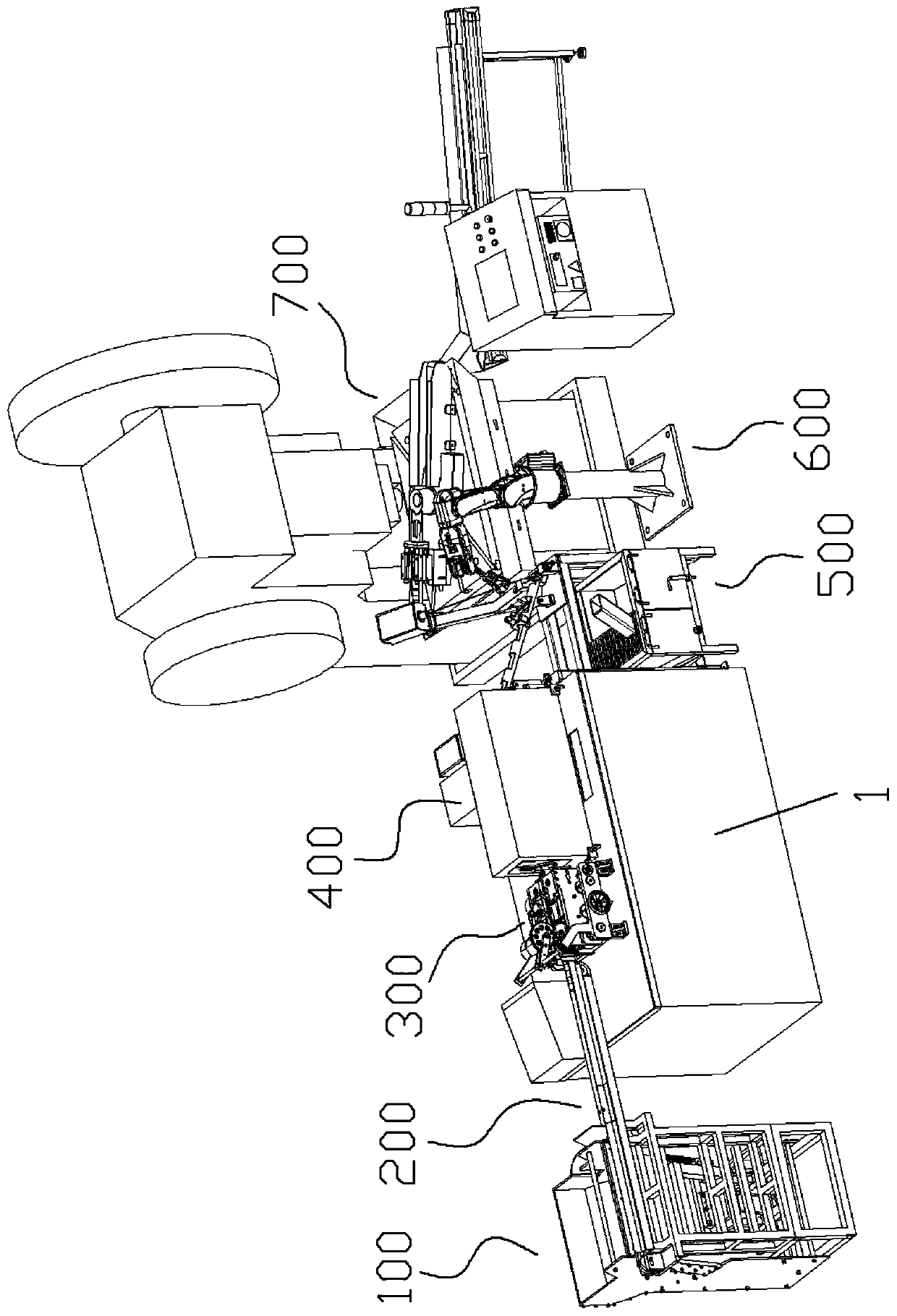

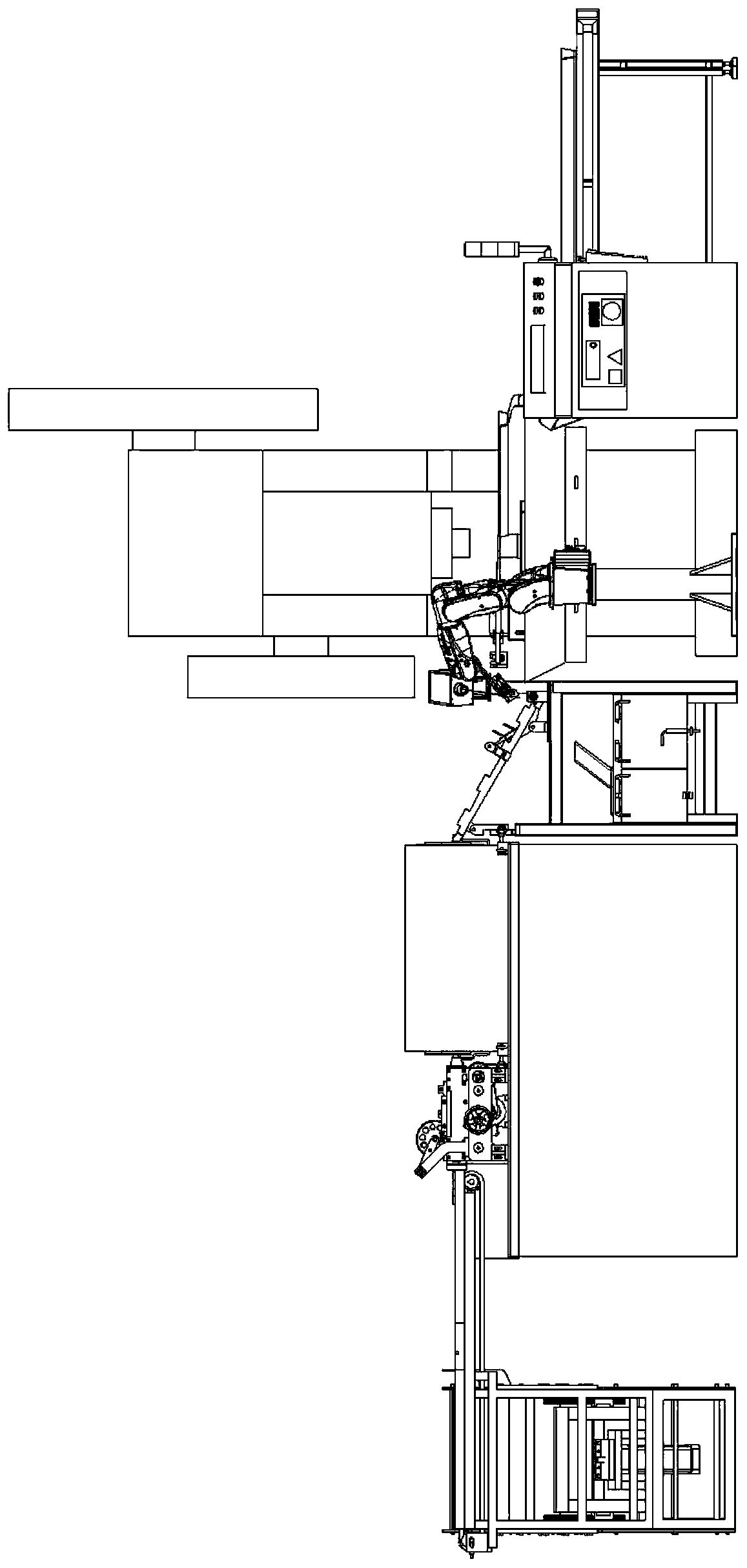

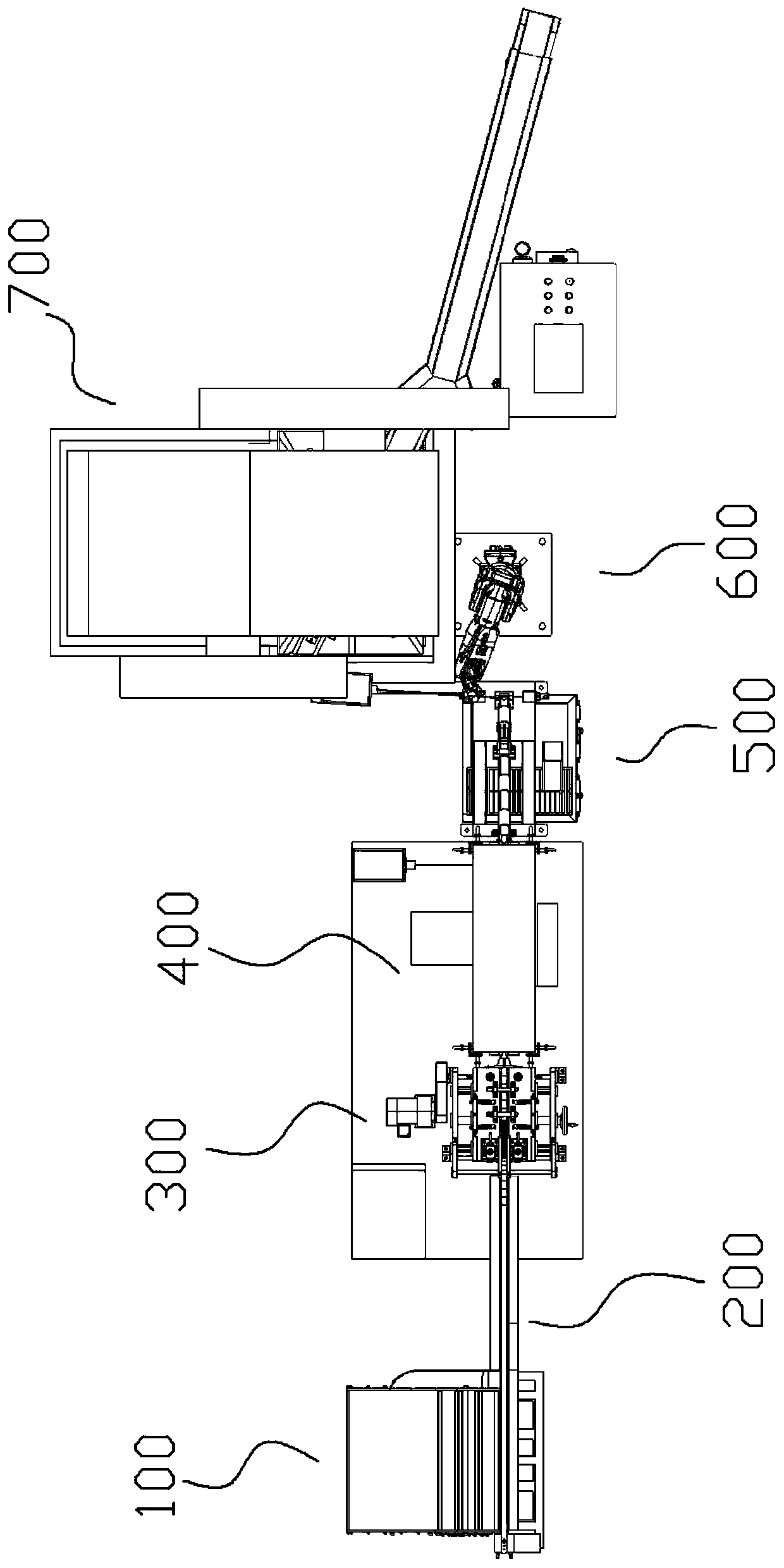

[0028] according to figure 1 , 2 , 3, this scheme provides an automatic forging production line, including a feeding machine (100), a conveyor (200), a clamping feeding mechanism (300), an intermediate frequency heating furnace (400), and a feeding guide arranged in sequence Mechanism (500), joint robot (600) and punch press (700); the discharge end of the feeder (100) is aligned with one end of the conveyor (200), the conveyor (200) is horizontally set, and the conveyor (200 ) is connected to the inlet of the clamping feeding mechanism (300), the discharge port of the clamping feeding mechanism (300) is connected to the inlet of the intermediate frequency heating furnace (400), and the outlet of the intermediate frequency heating furnace (400) is provided with a blanking guide Mechanism (500), the end of the blanking guide mechanism (500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com