Bearing inner ring with V-shaped narrow oil groove and processing method

A bearing inner ring, narrow technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of narrow oil grooves and small space for empty tools, achieve high-altitude tool space, and ensure the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

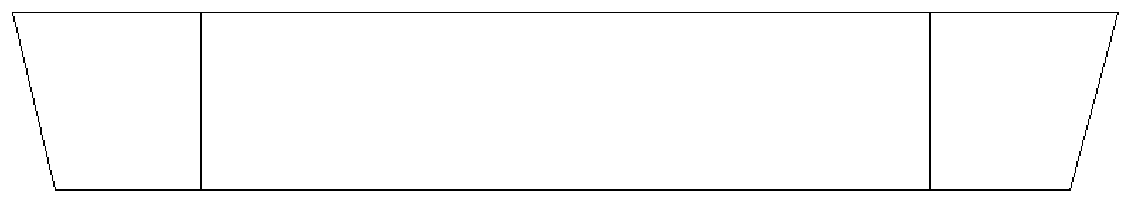

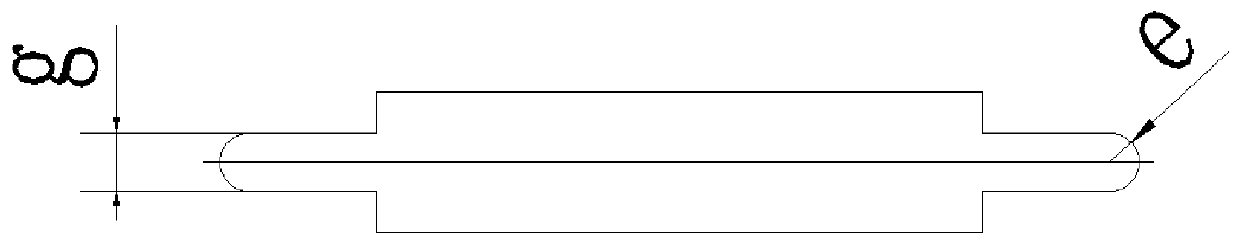

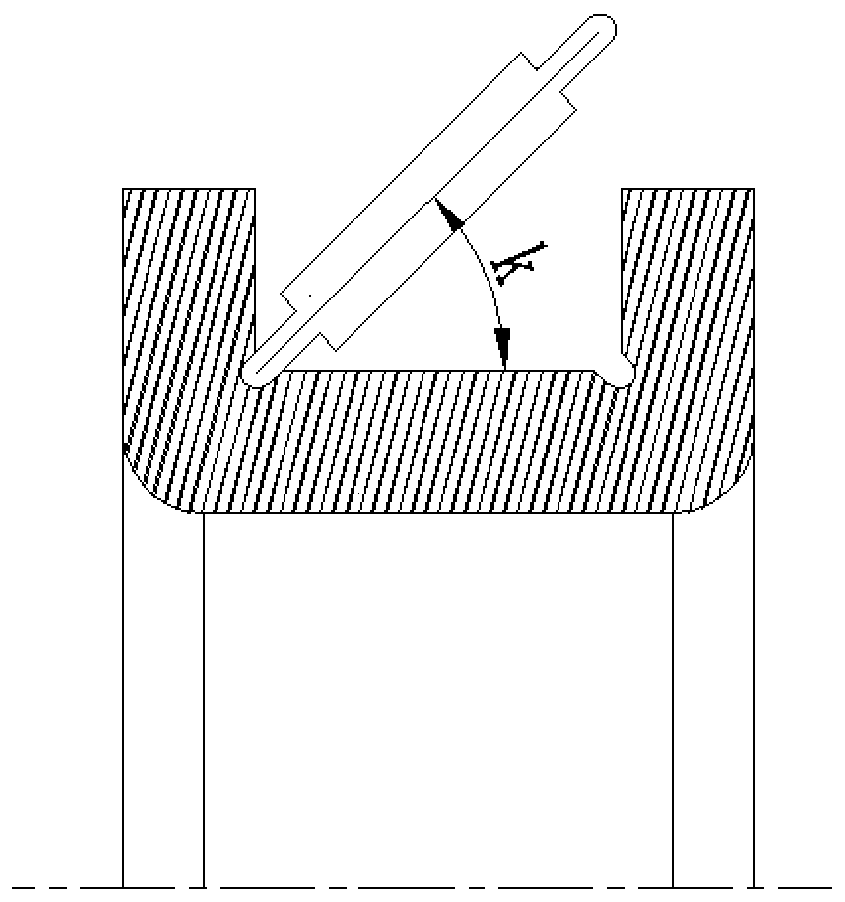

[0036] Specific implementation mode 1: In this embodiment, the bearing inner ring with a V-shaped narrow oil groove is composed of a narrow oil groove and a bearing inner ring, and the narrow oil groove is arranged at the intersection of the rib and the raceway in the bearing inner ring; The cross section of the narrow oil groove is V-shaped, the groove bottom of the narrow oil groove is arc-shaped, the angle between the two side walls of the narrow oil groove is 26°~26.5°, and the centerline of the cross section of the narrow oil groove is in line with the bearing The angle between the raceway planes of the inner ring is 55°.

[0037] The narrow oil groove in this embodiment is V-shaped, and the included angle between the two side walls is 26°-26.5°. Compared with the existing U-shaped, it has a higher empty knife space, which can meet the needs of subsequent raceways, stoppers, etc. Side and other processing needs to ensure the pass rate of products.

specific Embodiment approach 2

[0038] Specific embodiment two: In this embodiment, the method for processing the bearing inner ring with a V-shaped narrow oil groove in this embodiment is carried out according to the following steps:

[0039] (1) Turning of bearing inner ring blanks:

[0040] Firstly, fine-turn surface A, fine-turn inner diameter, chamfer the inner diameter of surface A, and chamfer the outer diameter of surface A; The inner diameter chamfering of the B surface and the outer diameter chamfering of the B surface; the final rough car oil groove;

[0041] (2) Perform heat treatment on the bearing inner ring obtained in step (1); heat treatment can change the internal structure of the bearing to meet the requirements of bearing structure and hardness;

[0042] (3) The inner ring of the bearing obtained in step (2) is subjected to rough grinding of both end surfaces, rough grinding of the outer diameter, rough grinding of the inner diameter, rough grinding of ribs and rough grinding of the race...

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the processing parameters of the fine turning A surface, fine turning inner diameter, fine turning B surface and fine turning outer diameter of step (1): cutting speed Vc: 160 ~180m / min, feed rate f: 0.15~0.25mm / min, cutting depth ap: 0.5~1.5mm; the A surface and B surface are the two end surfaces of the inner ring of the bearing;

[0053] Processing parameters of the thin car raceway in step (1): cutting speed Vc: 80-100m / min, feed rate f: 0.03-0.05mm / min;

[0054]The processing parameters of the rough car oil groove in step (1): cutting speed Vc: 80-100 m / min, feed rate f: 0.05-0.1 mm / min. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com