Device for changing waste roller into shared umbrella placement vehicle and manufacturing method

A manufacturing method and drum technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as waste of time, single function of cutting device, low efficiency, etc., to save time, improve maximum utilization, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

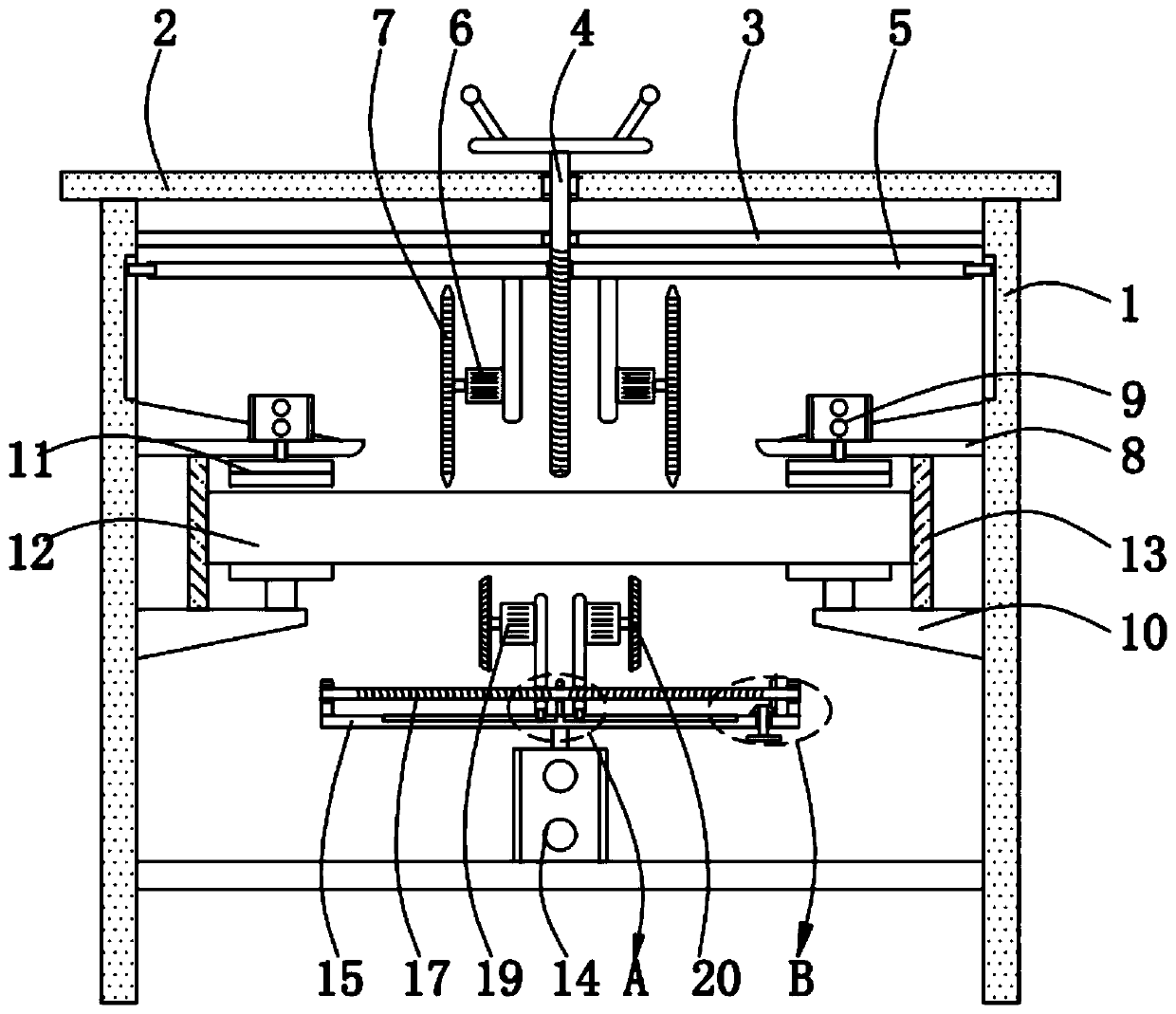

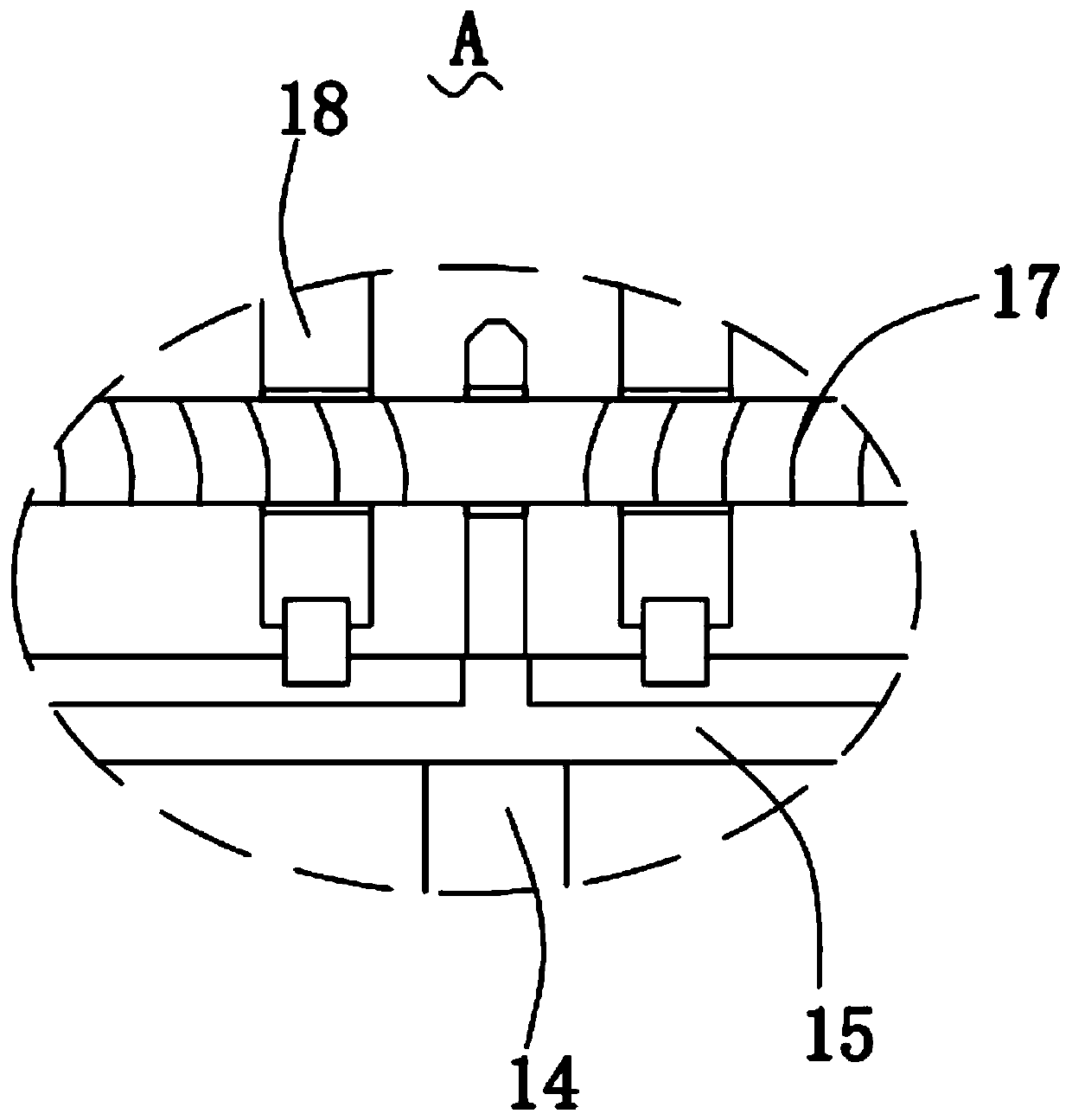

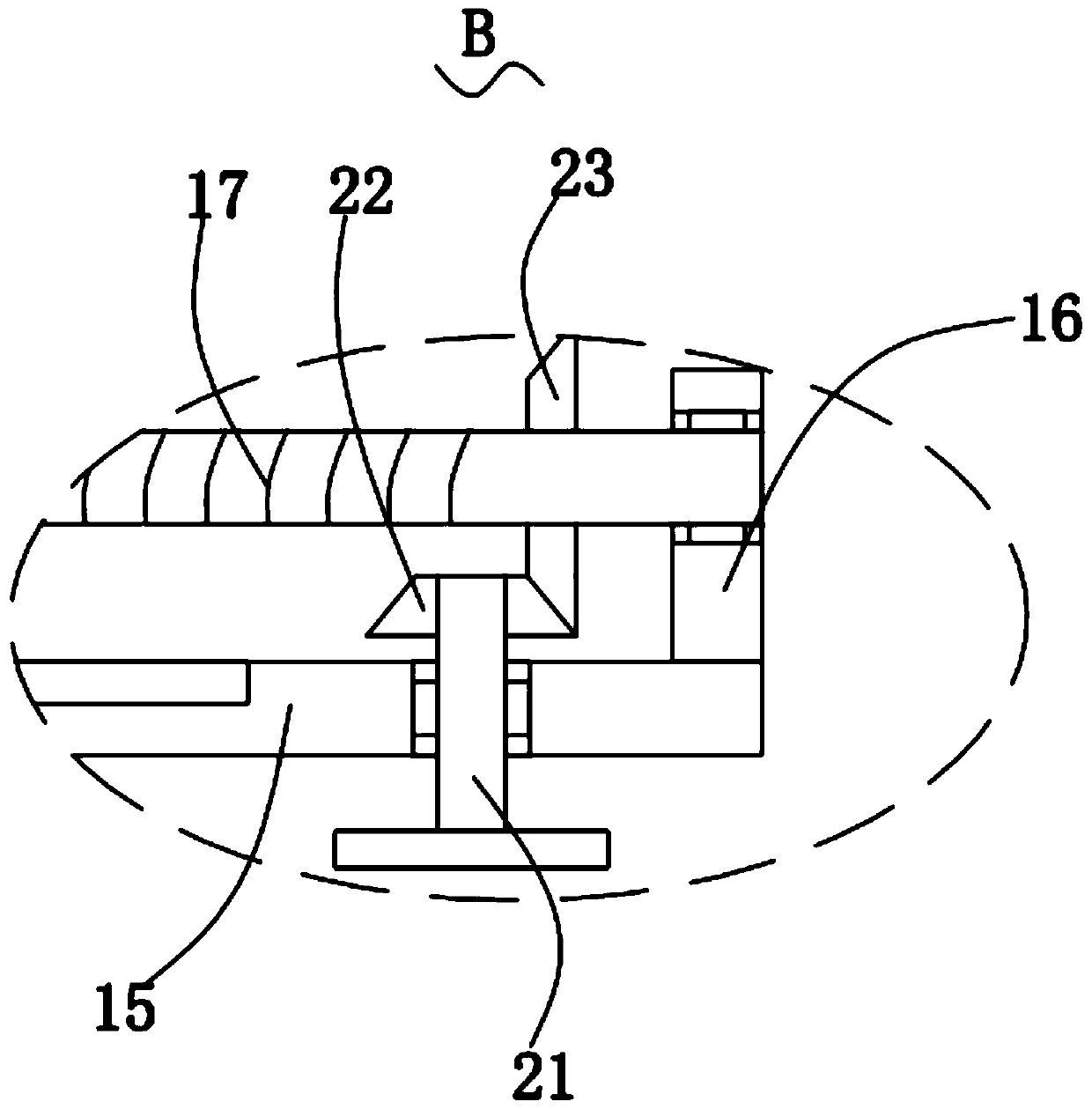

[0028] Please refer to Figure 1-Figure 4 ,in figure 1 It is a structural schematic diagram of a preferred embodiment of a device for refitting a shared umbrella with a discarded roller proposed by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 The enlarged schematic diagram of part B shown; Figure 4 for figure 1 Schematic diagram of the side view structure of the curved splint shown.

[0029] In this embodiment, a device for refitting a shared umbrella with discarded rollers is proposed, including two side fixing plates 1; a cover plate 2, and the cover plate 2 is fixedly installed on the top of the two side fixing plates 1; a reinforcing plate 3. The reinforcing plate 3 is fixedly installed on the side where the two side fixing plates 1 are close to each other; the first screw 4, the first screw 4 is rotatably installed on the cover plate 2 and the reinforcing plate 3 On the movable plate 5, the mov...

Embodiment 2

[0039] In this embodiment, a method for making a vehicle for refitting a shared umbrella with discarded rollers is proposed, including the following steps:

[0040] S1: Material selection: Select a suitable waste roller, two sealing plates that match the diameter of the roller, two iron sheets for umbrella storage, three connecting rods, a load-bearing base and four universal wheels.

[0041] S2: Cutting into sections: Cut the selected waste drum into two sections of the same size, and then polish the cut surface.

[0042] S3: Material welding: Weld two sealing plates on one side of the two-section drum respectively to seal the opening on one side, and then weld the two umbrella storage iron plates on the other opening side of the two-section drum respectively, and then The three connecting rods are welded on the top of the load-bearing base, and the two rollers are welded to the three connecting rods. The distance between the two rollers can be adjusted according to the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com