Floor drain type drainage device for aluminum alloy ship

A drainage device and aluminum alloy technology, which is applied in the direction of ship soil drainage, water supply devices, drainage structures, etc., can solve the problems of blockage and removal of the floor drain drainage device, and the lack of limit structure of the filter net, so as to avoid water accumulation and improve drainage efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

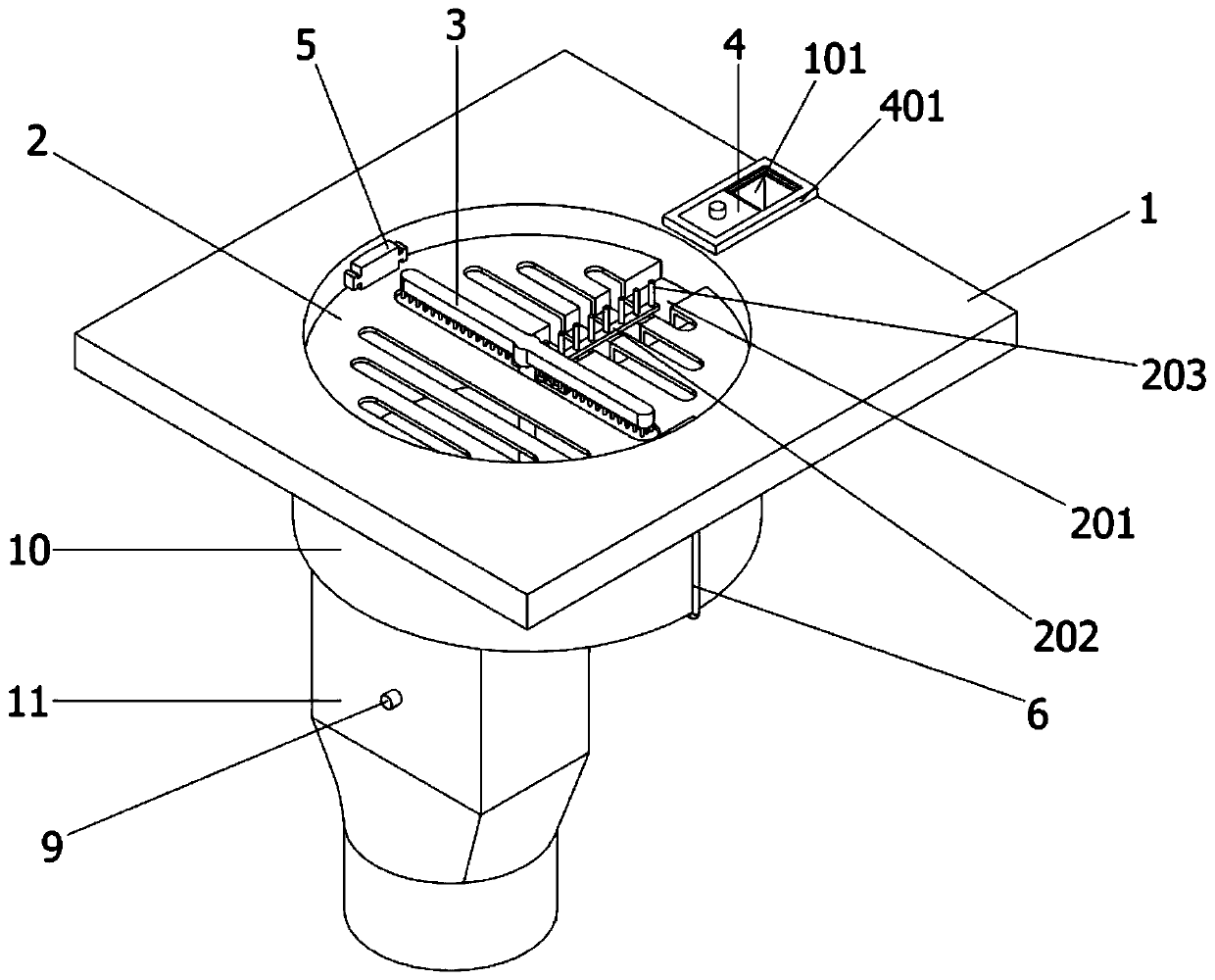

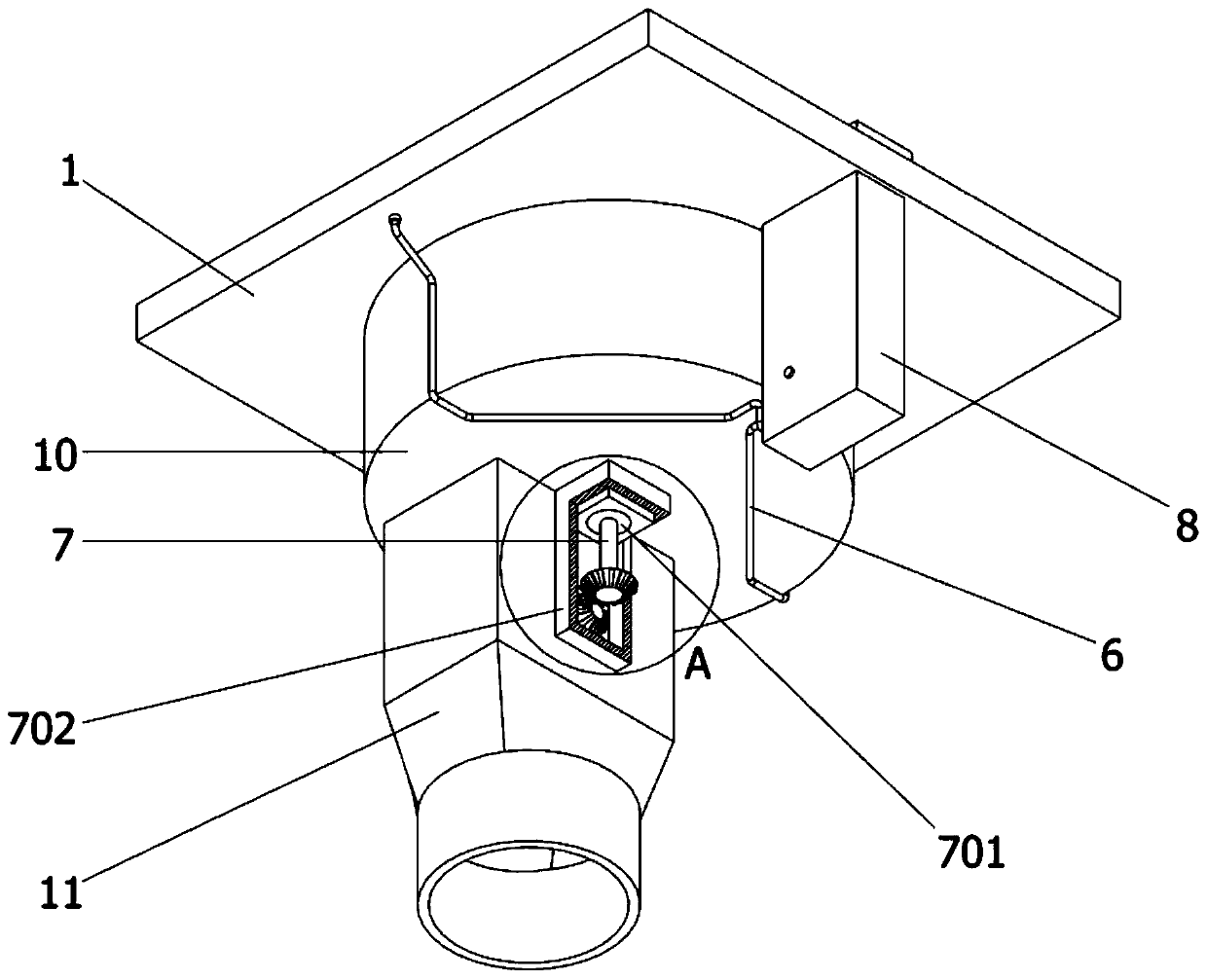

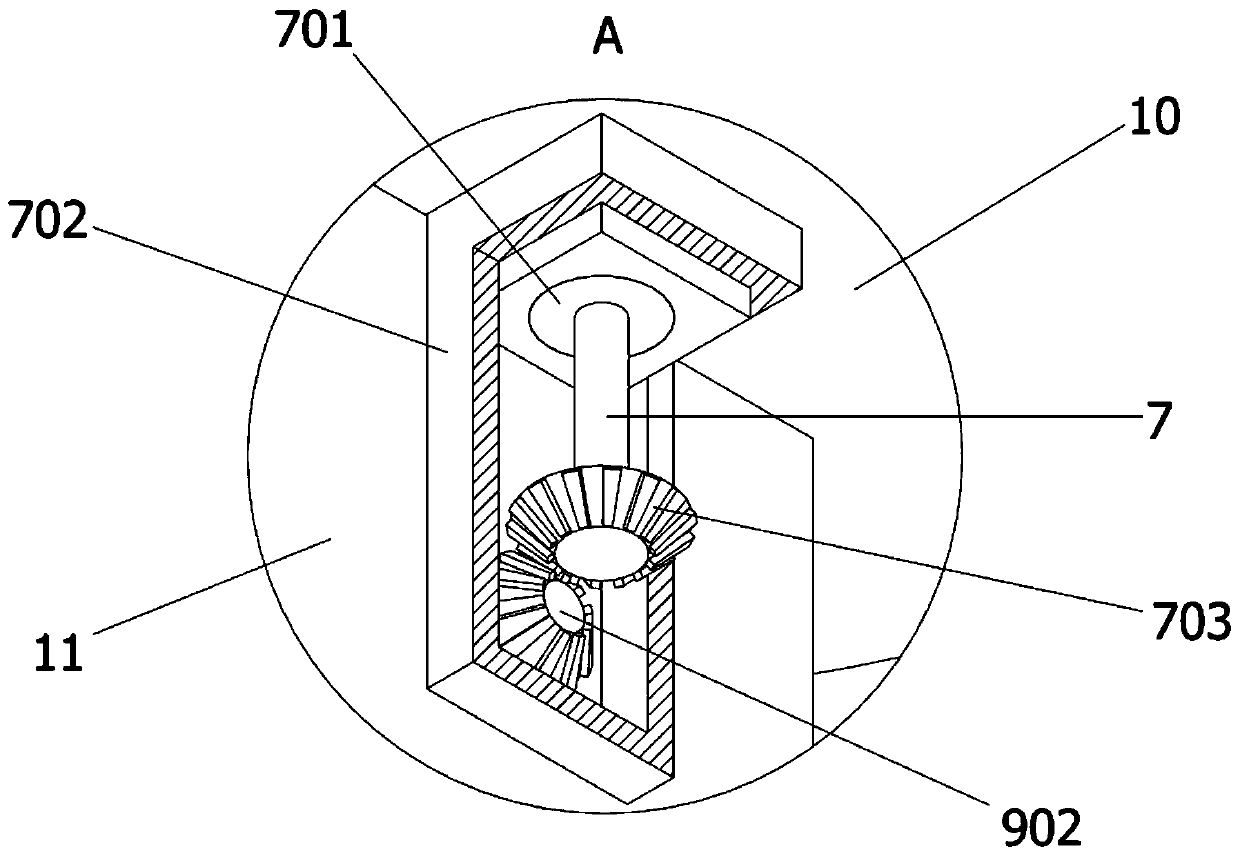

[0035] as attached figure 1 to attach Figure 11 Shown:

[0036] The present invention provides a floor drain type drainage device for aluminum alloy ships, comprising: a floor drain base plate 1, a circular water drop box 10 is provided at the bottom of the floor drain base plate 1, and an inner peripheral surface of the circular water drop box 10 is provided on the upper surface of the floor drain base plate 1 A circular water inlet with the same size. The floor drain base plate 1 also includes a rectangular opening 101, a limit mechanism chute 102, a pulley 103 and an annular groove 104. The upper end of the floor drain base plate 1 is located at the sealing shield plate 4. A rectangular opening is opened 101, and the interior of the rectangular port 101 communicates with the interior of the protection mechanism 8, and the interior of the floor drain substrate 1 is symmetrically provided with two limit mechanism chutes 102, and each limit mechanism chute 102 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com