Automatic feeding device for bamboo splits

A technology of automatic feeding and bamboo strips, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problem of low production efficiency of bamboo winding composite products, affecting the production cost of bamboo composite products, downtime or speed reduction, etc. To ensure the accuracy and efficiency of preparation, reduce labor and labor costs, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

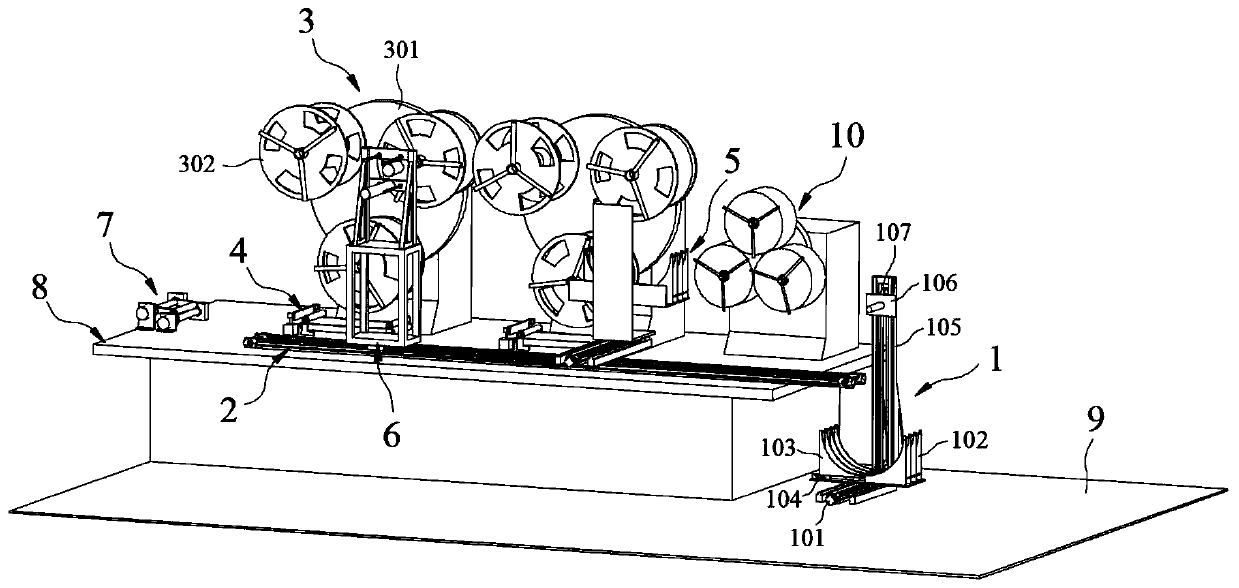

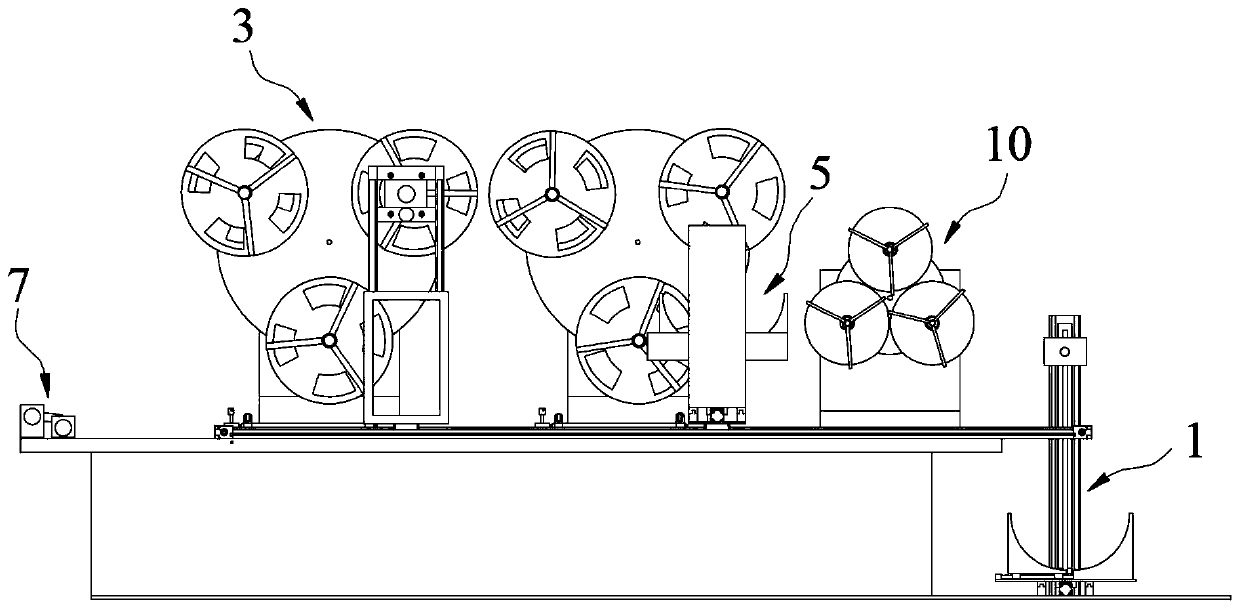

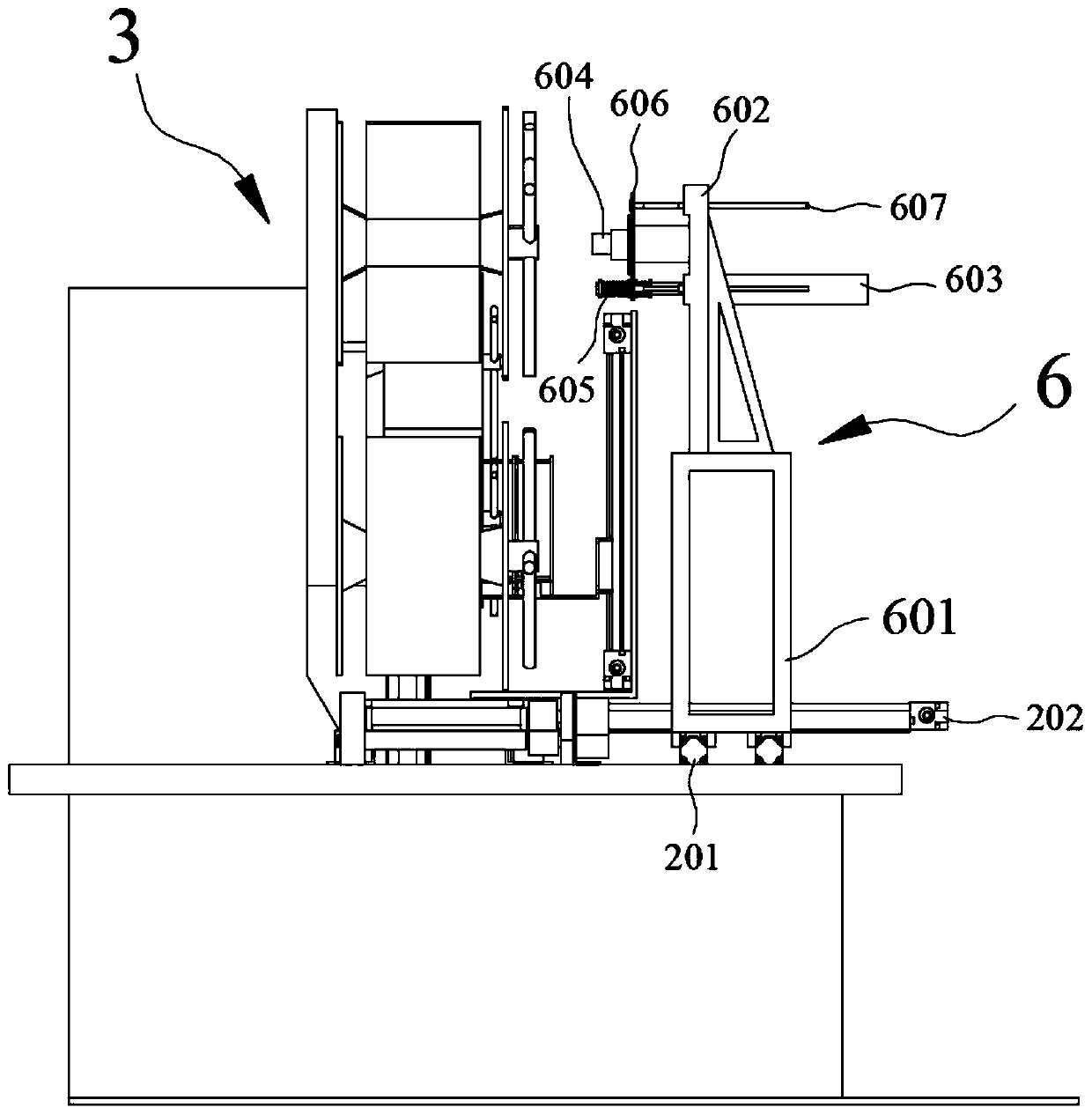

[0042] see Figure 1-8 , the automatic feeding device for bamboo strips in the preferred embodiment of the present invention is arranged on the base 9, which includes the lifting tool 1 and the workbench 8 arranged on the base 9, and the displacement assembly 2 and the positioning turntable arranged on the workbench 8 Tooling 3, feeding cutting tooling 4, tray feeding tooling 5, automatic tightening tooling 6 and discharging tooling 7. Wherein, the tray feeding tool 5 and the automatic tightening tool 6 are correspondingly arranged on the displacement assembly 2, and are respectively used for feeding the bamboo strip tray 302 and setting the bamboo strip tray 302 in the row of the feeding tray 301. Further, the feed cutting tool 4 is set corresponding to the positioning turntable tool 3, and is used for feeding and cutting the bamboo strips corresponding to the bamboo strip tray 302, and the discharging tool 7 is arranged on the workbench 8, and is used to cut off the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com