Substrate evaporation bearing plate and vacuum evaporation instrument

A technology for substrates and trays, applied in the field of machinery, can solve the problems of fewer types of evaporation substrates and insufficient utilization of the space of substrate evaporation trays, etc., to improve space utilization, increase types and numbers, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

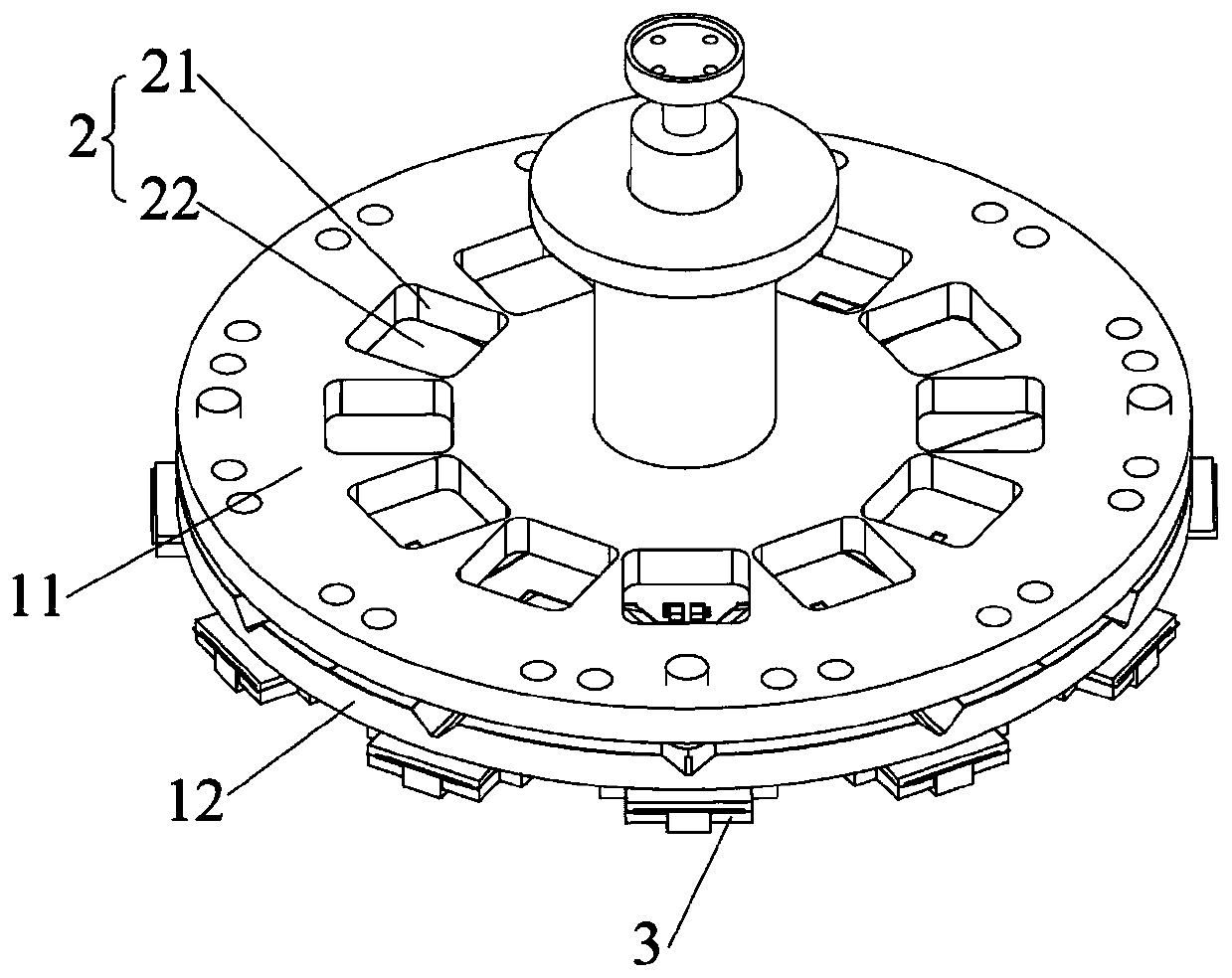

[0041] This embodiment provides a substrate evaporation carrying plate, which is used in a vacuum evaporation apparatus. The substrate evaporation carrying plate can place multiple substrates, and there are many types of evaporation substrates, which improves the efficiency of substrate evaporation. Space utilization of plated carrier trays.

[0042] Specifically, such as figure 1 and figure 2 As shown, the substrate evaporation carrier includes a chassis and a baffle assembly 3, the chassis is provided with a plurality of bearing parts 2 for placing substrates, the baffle assembly 3 is arranged below the chassis, and the baffle assembly 3 can be opposite to the chassis. Movement, and the baffle assembly 3 is used to switch whether to evaporate and switch the desired evaporation pattern 4. During the evaporation process, the baffle assembly 3 can block the evaporation pattern 4 so that the corresponding substrate does not have the evaporation pattern, and can also switch th...

Embodiment 2

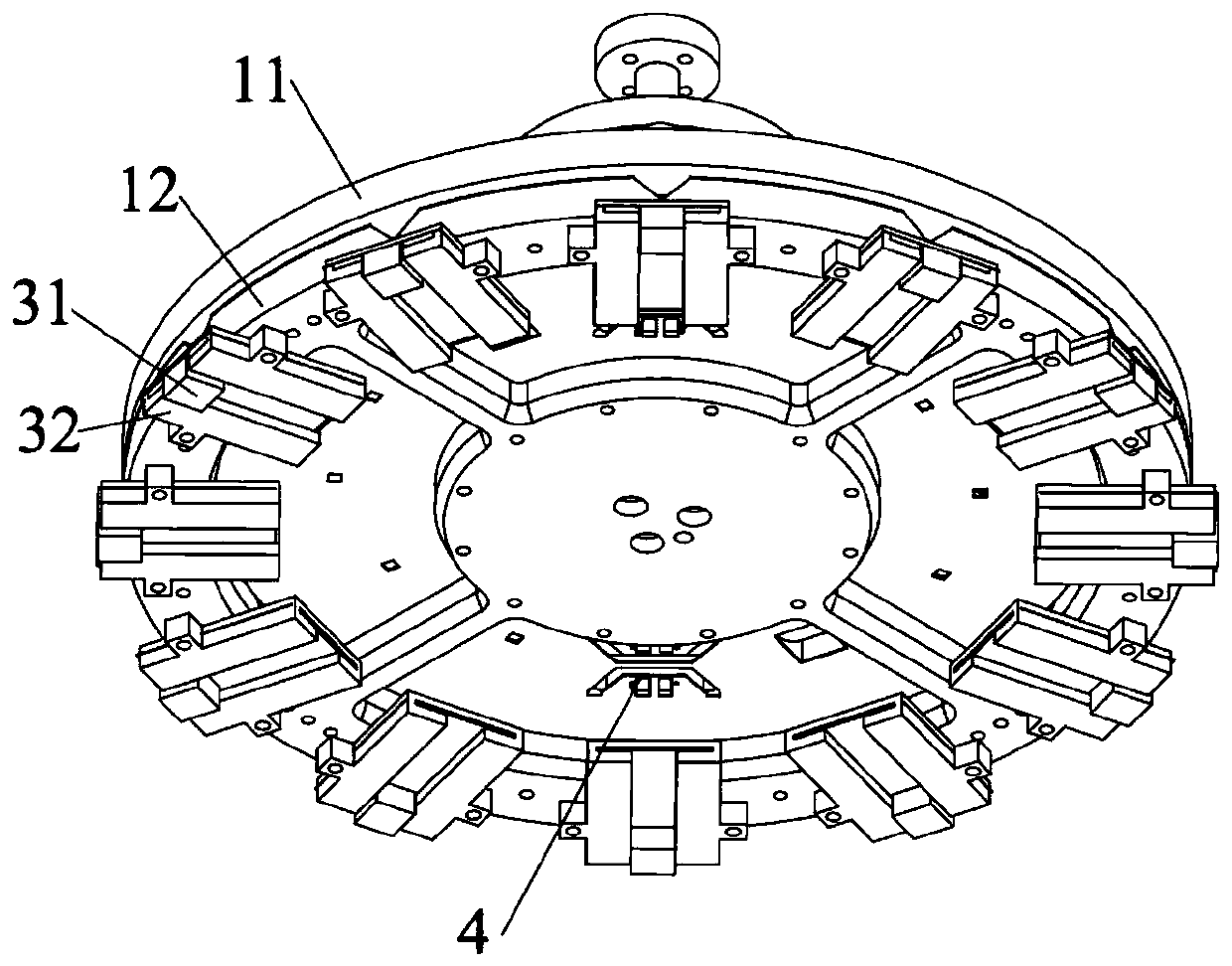

[0051] This embodiment provides a substrate evaporation carrying plate, which is used in a vacuum evaporation apparatus. The substrate evaporation carrying plate can place multiple substrates, and there are many types of evaporation substrates, which improves the efficiency of substrate evaporation. Space utilization of plated carrier trays.

[0052] Specifically, such as Figure 4 and Figure 5 As shown, the substrate evaporation carrier includes a chassis and a baffle assembly 3, the chassis is provided with a plurality of bearing parts 2 for placing substrates, the baffle assembly 3 is arranged below the chassis, and the baffle assembly 3 can be opposite to the chassis. Movement, and the baffle assembly 3 is used to switch whether to evaporate and switch the desired evaporation pattern 4. During the evaporation process, the baffle assembly 3 can block the evaporation pattern 4 so that the corresponding substrate does not have the evaporation pattern, and can also switch t...

Embodiment 3

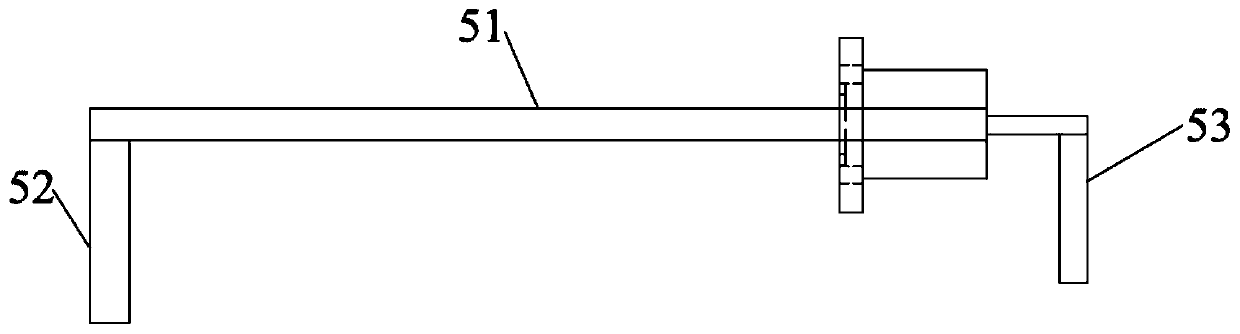

[0059] This embodiment provides a substrate evaporation carrying plate, which is used in a vacuum evaporation apparatus. The substrate evaporation carrying plate can place multiple substrates, and there are many types of evaporation substrates, which improves the efficiency of substrate evaporation. Space utilization of plated carrier trays.

[0060] Specifically, such as Figure 7 and Figure 8 As shown, the substrate evaporation carrier includes a chassis and a baffle assembly 3, the chassis is provided with a plurality of bearing parts 2 for placing substrates, the baffle assembly 3 is arranged below the chassis, and the baffle assembly 3 can be opposite to the chassis. Movement, and the baffle assembly 3 is used to switch whether to evaporate and switch the desired evaporation pattern 4. During the evaporation process, the baffle assembly 3 can block the evaporation pattern 4 so that the corresponding substrate does not have the evaporation pattern, and can also switch t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com