Pickling device used for electronic components

A technology for electronic components and pickling equipment, applied in the field of electronic components, can solve the problems of insufficient contact, high operation risk, and acid liquid corrodes the skin, etc., and achieves the effect of simple structure, convenient use, and quality and safety assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

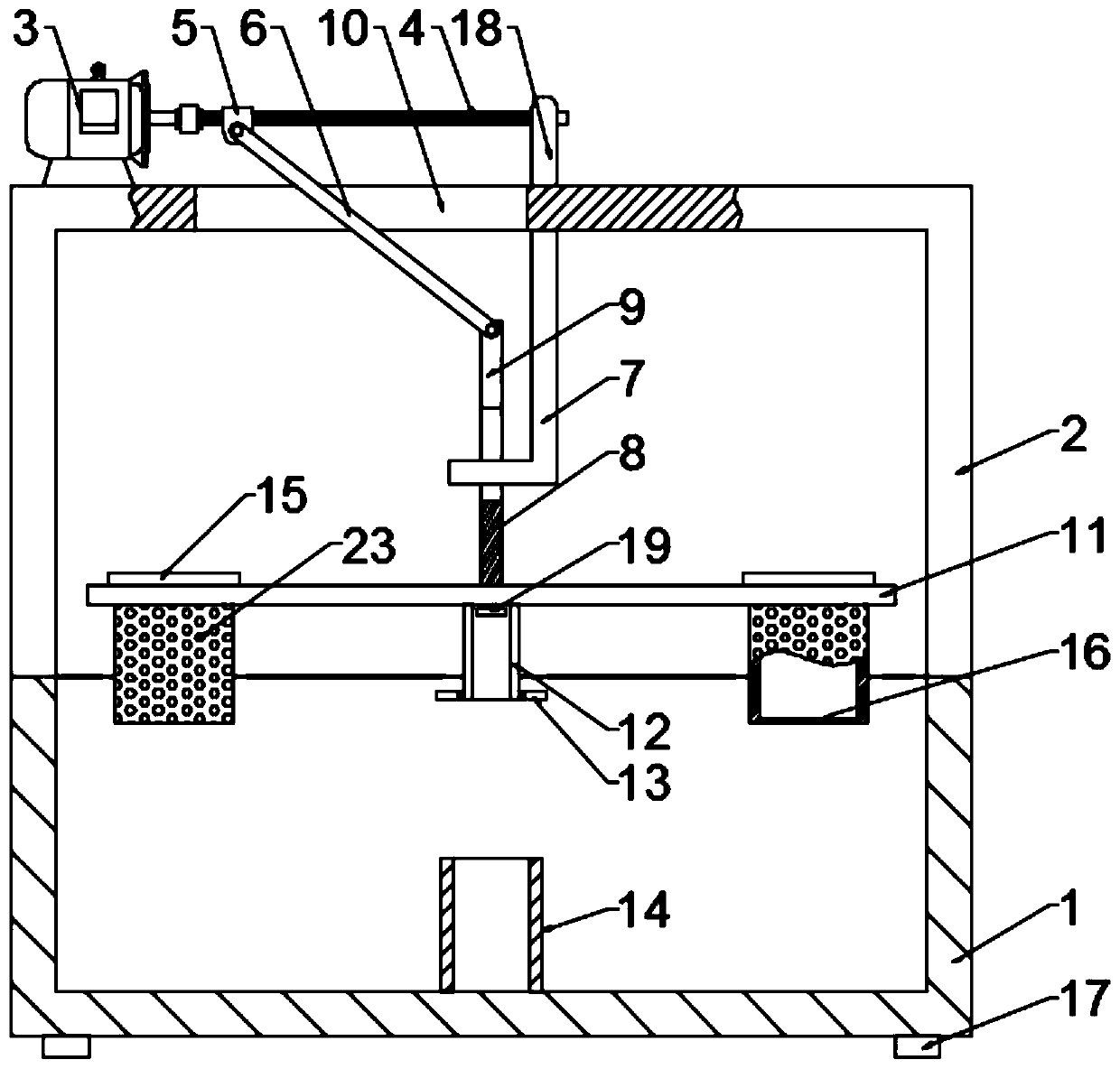

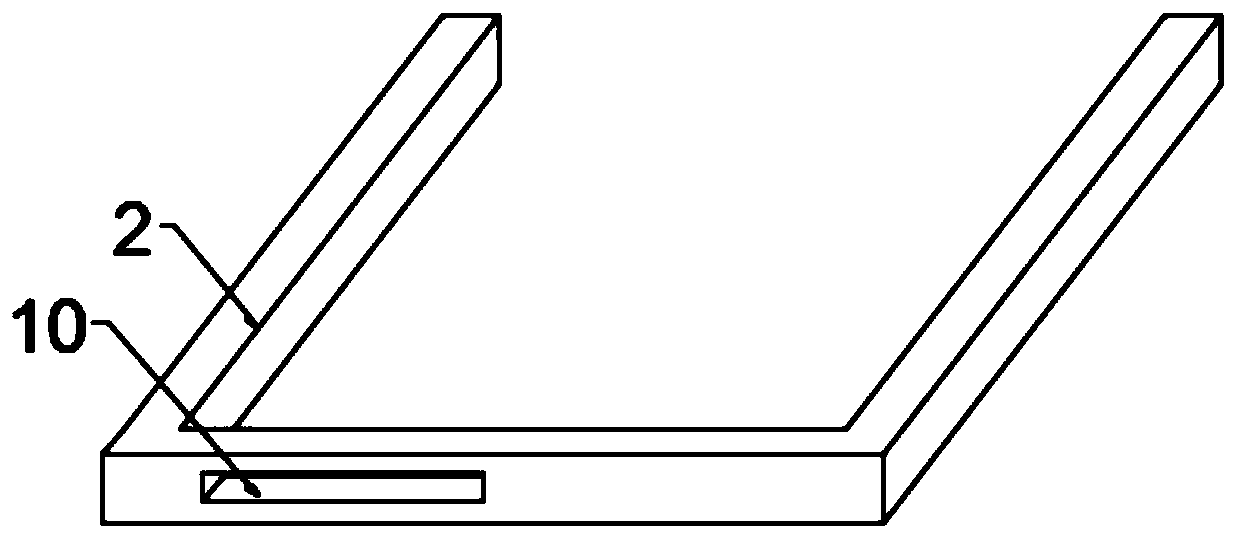

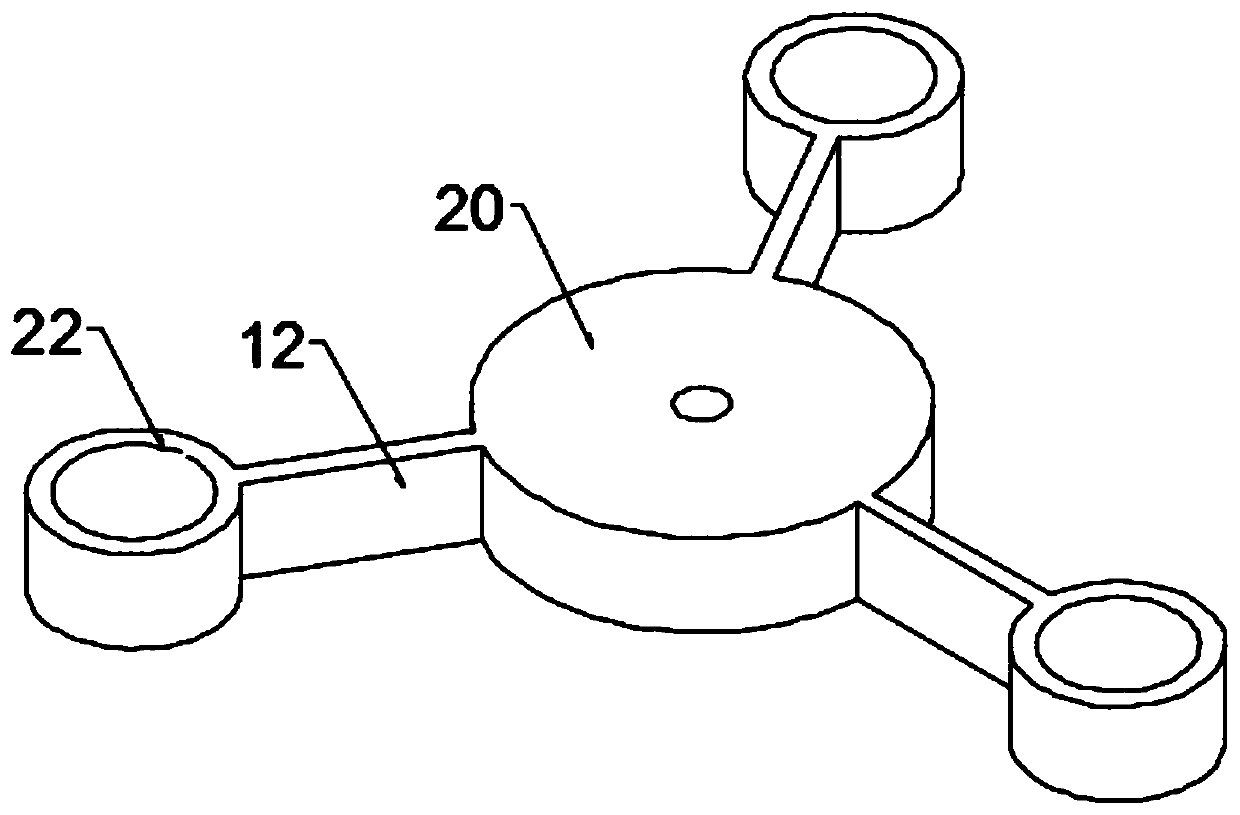

[0023] Example 1: Please refer to Figure 1-3 , a pickling equipment for electronic components, comprising a pickling solution storage box 1, the top of the pickling solution storage box 1 is fixedly connected with a door-shaped bracket 2, and the left side of the top of the door-shaped bracket 2 is fixedly connected with a motor 3 , the output end of the motor 3 is connected with a horizontal screw 4 through a coupling, the outer thread of the horizontal screw 4 is connected with a sliding screw sleeve 5, and the lower part of the sliding screw sleeve 5 is connected with a tilting push rod 6, and the door-shaped bracket 2 The bottom is fixedly connected with the guide seat 7, the inner side of the guide seat 7 slides up and down and connected with the longitudinal screw 8, the upper part of the longitudinal screw 8 is fixedly connected with the connecting end 9, the upper part of the door bracket 2 is provided with a through groove 10, and the inclined push rod 6 runs through ...

Embodiment 2

[0034] Example 2: Please refer to Figure 1-3 , a pickling equipment for electronic components, comprising a pickling solution storage box 1, the top of the pickling solution storage box 1 is fixedly connected with a door-shaped bracket 2, and the left side of the top of the door-shaped bracket 2 is fixedly connected with a motor 3 , the output end of the motor 3 is connected with a horizontal screw 4 through a coupling, the outer thread of the horizontal screw 4 is connected with a sliding screw sleeve 5, and the lower part of the sliding screw sleeve 5 is connected with a tilting push rod 6, and the door-shaped bracket 2 The bottom is fixedly connected with the guide seat 7, the inner side of the guide seat 7 slides up and down and connected with the longitudinal screw 8, the upper part of the longitudinal screw 8 is fixedly connected with the connecting end 9, the upper part of the door bracket 2 is provided with a through groove 10, and the inclined push rod 6 runs through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com