Explosion-proof FID

An explosion-proof, cylindrical component technology, applied in the field of FID, can solve the problems of low signal-to-noise ratio of FID, water accumulation inside the online instrument, damage to the signal board, etc., and achieve safe and reliable structure, high signal-to-noise ratio and low detection limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

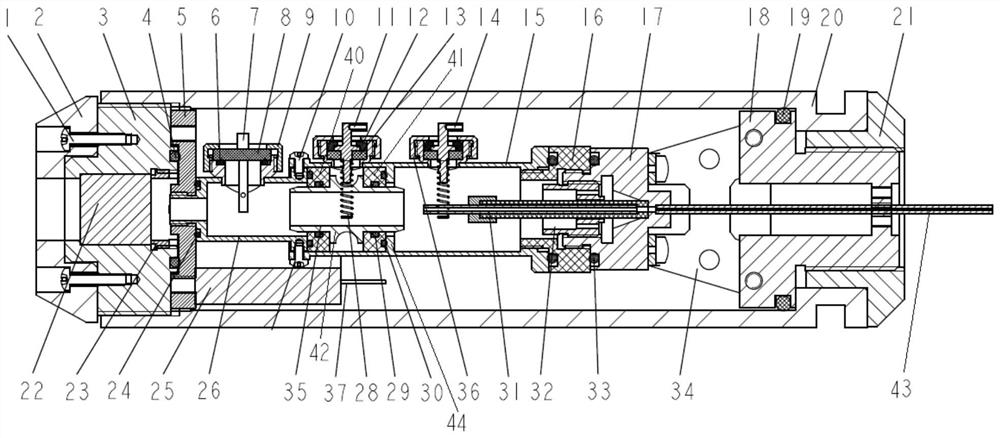

[0025] figure 1 A schematic structural diagram of the explosion-proof FID of the embodiment of the present invention is given, as figure 1 As shown, the explosion-proof FID includes:

[0026] The first cylindrical part 20, and the ignition wire 7, the collecting pole 28 and the polarizing pole 14 arranged in the first cylindrical part 20 are prior art in this field;

[0027] The second cylindrical part, the second cylindrical part is arranged inside the first cylindrical part 20, and is respectively connected with the upstream part and the downstream part, and isolates the inside of the first cylindrical part 20 as the first cylindrical part. The part inside the second cylindrical part, and the interlayer part between the second cylindrical part and the first cylindrical part;

[0028] a nozzle 31, the nozzle 31 is arranged in the second cylindrical part, and is used for transmitting sample gas;

[0029] The polarized pole 14, the collecting pole 28 and the ignition wire 7 ...

Embodiment 2

[0062] An application example of the explosion-proof FID according to Embodiment 1 of the present invention.

[0063] In this application example, if figure 1 As shown, the explosion-proof FID includes:

[0064] a first cylindrical member 20 having a larger inner diameter portion and a smaller inner diameter portion;

[0065] The upstream part includes a first end cover 21, a pipe fixing part 18, a bracket 34, a gas mixing part 17 and an adapter 16 arranged sequentially from outside to inside: the gas mixing part 17 is arranged on the first cylindrical part 20 The inner side of the larger part of the inner diameter has a gas passage arranged along the central axis of the gas mixing part. One end of the first gas pipe 43 is inserted into the gas passage and extends to the outside of the first cylindrical part 20; the nozzle 31 is inserted into the The gas channel passes through the air nozzle 32 and the adapter 16; the air nozzle 32 is arranged in the gas mixing part 17; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com