Odor-proof garment fabric

A technology for garments and fabrics, applied in the field of deodorant garment fabrics, can solve the problems of increased difficulty in mass production of garment fabrics, unsuitable for large-scale promotion and use, complicated preparation methods, etc., and achieves significant deodorization and antibacterial effects, high finished product qualification rate, and preparation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

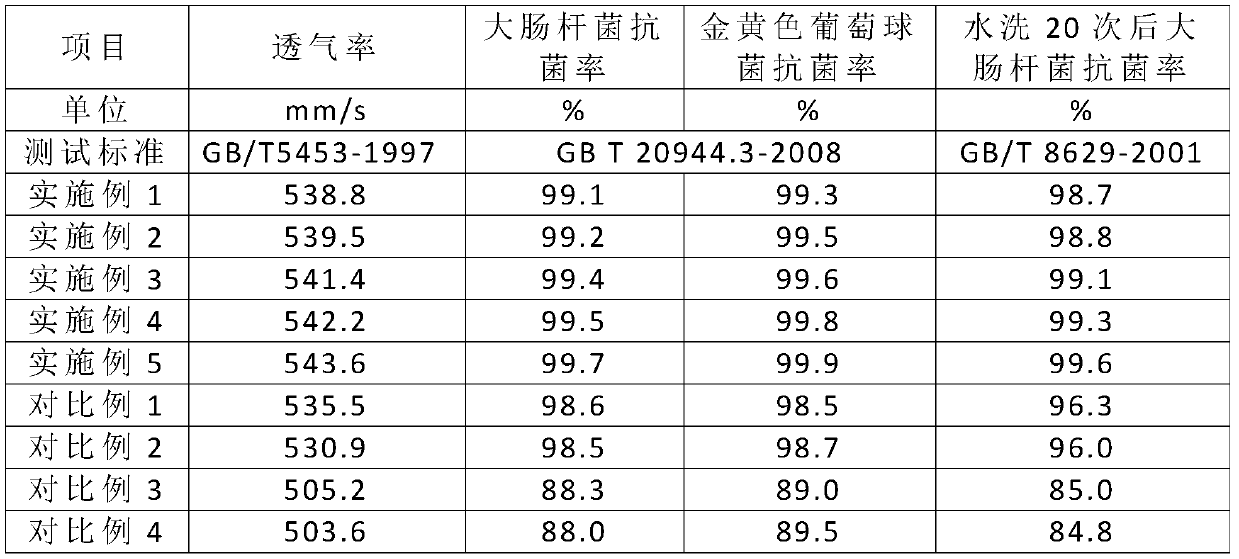

Examples

Embodiment 1

[0028] A deodorant clothing fabric is characterized in that it is made of the following raw materials in parts by weight: 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methylimino Diacetate / tetrahydroxystilbene glycoside / 16,17-epoxy progesterone modified cefditoren core copolymer 80 parts, allyl cyclodextrin 5 parts, azobisisobutyronitrile 1 part, Amino functionalized MOFs metal frame 8 parts, pearl powder 5 parts.

[0029]The 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methyliminodiacetate / tetrahydroxystilbene glycoside / 16,17-epoxy The preparation method of progesterone modified cefditoren core copolymer comprises the steps of: 5-vinyl-2-thiazolamine 1kg, two (triethoxysilyl) ethylene 0.5kg, 4-vinylphenylboronic acid methyl Add 0.2kg of iminodiacetate, 0.8kg of tetrahydroxystilbene glycoside, 0.5kg of 16,17-epoxy progesterone modified cefditoren core, and 0.03kg of benzoin dimethyl ether to 10kg of dimethy...

Embodiment 2

[0033] A deodorant clothing fabric is characterized in that it is made of the following raw materials in parts by weight: 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methylimino Diacetate / Tetrahydroxystilbene Glycoside / 16,17-Epoxyprogesterone Modified Cefditoren Core / Allyl Cyclodextrin Copolymer 85 parts, Allyl Cyclodextrin 6 parts, Azo 1.5 parts of diisobutyronitrile, 9 parts of amino-functionalized MOFs metal framework, and 6 parts of pearl powder.

[0034] The 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methyliminodiacetate / tetrahydroxystilbene glycoside / 16,17-epoxy The preparation method of progesterone modified cefditoren core copolymer comprises the steps of: 5-vinyl-2-thiazolamine 1kg, two (triethoxysilyl) ethylene 0.5kg, 4-vinylphenylboronic acid methyl 0.2 kg of imino diacetate, 0.8 kg of tetrahydroxy stilbene glycoside, 0.5 kg of 16,17-epoxy progesterone modified cefditoren core, and 0.032 kg of...

Embodiment 3

[0038] A deodorant clothing fabric is characterized in that it is made of the following raw materials in parts by weight: 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methylimino Diacetate / tetrahydroxystilbene glycoside / 16,17-epoxy progesterone modified cefditoren core copolymer 90 parts, allyl cyclodextrin 8 parts, azobisisobutyronitrile 2 parts, Amino functionalized MOFs metal framework 10 parts, pearl powder 7.5 parts.

[0039] The 5-ethylene-2-thiazolamine / bis(triethoxysilyl)ethylene / 4-vinylphenylboronic acid methyliminodiacetate / tetrahydroxystilbene glycoside / 16,17-epoxy The preparation method of progesterone modified cefditoren core / allyl cyclodextrin copolymer comprises the following steps: 1kg of 5-ethylene-2-thiazolamine, 0.5kg of bis(triethoxysilyl)ethylene, 4-vinylphenylboronic acid methyliminodiacetate 0.2kg, tetrahydroxystilbene glycoside 0.8kg, 16,17-epoxy progesterone modified cefditoren core 0.5kg, benzoin isopropyl ether 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com