Method for manufacturing hyperbolic all-welded structural steel truss girder

An all-welded structure and manufacturing method technology, applied in bridges, truss bridges, bridge forms, etc., can solve the problems of lofting of main truss members, difficult manufacturing, large welding workload of steel beams, and many types of welded joints, etc. The manufacturing quality is easy to control, the nesting time is reduced, and the nesting personnel input is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

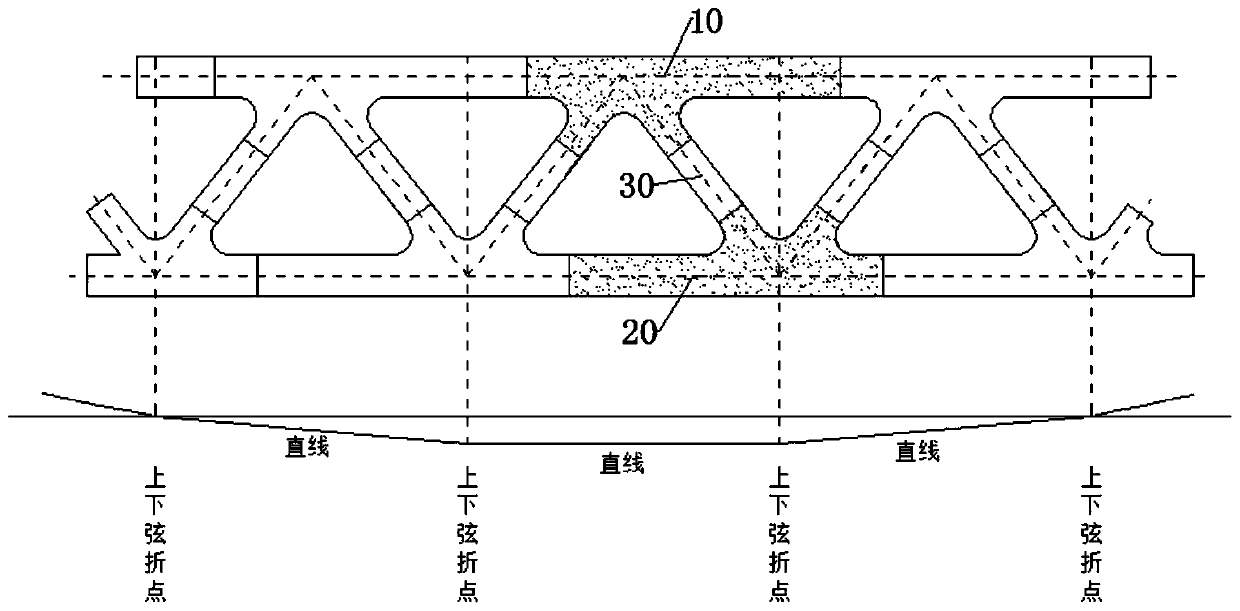

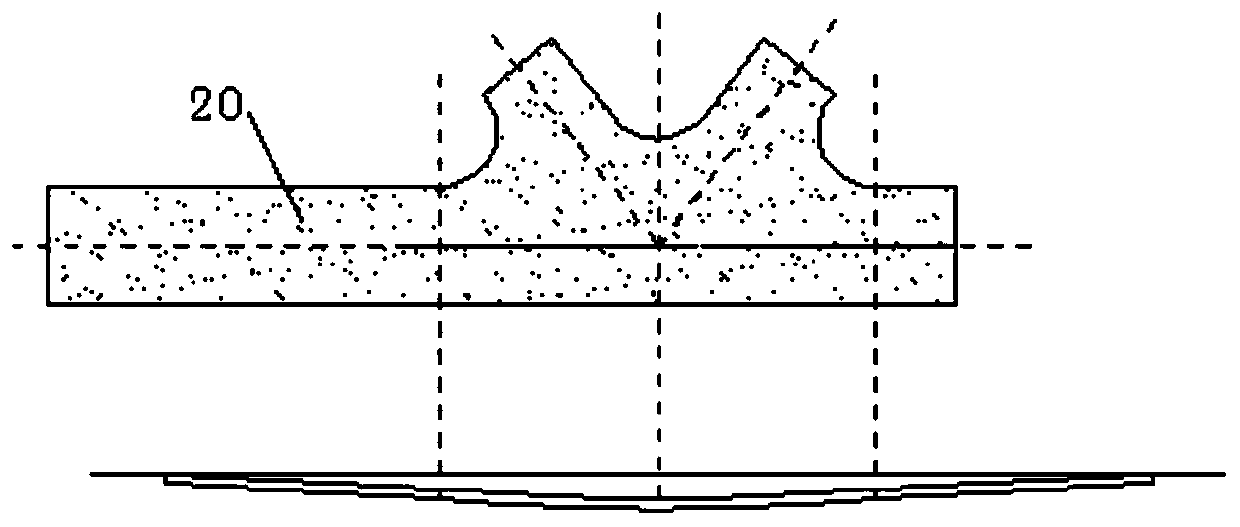

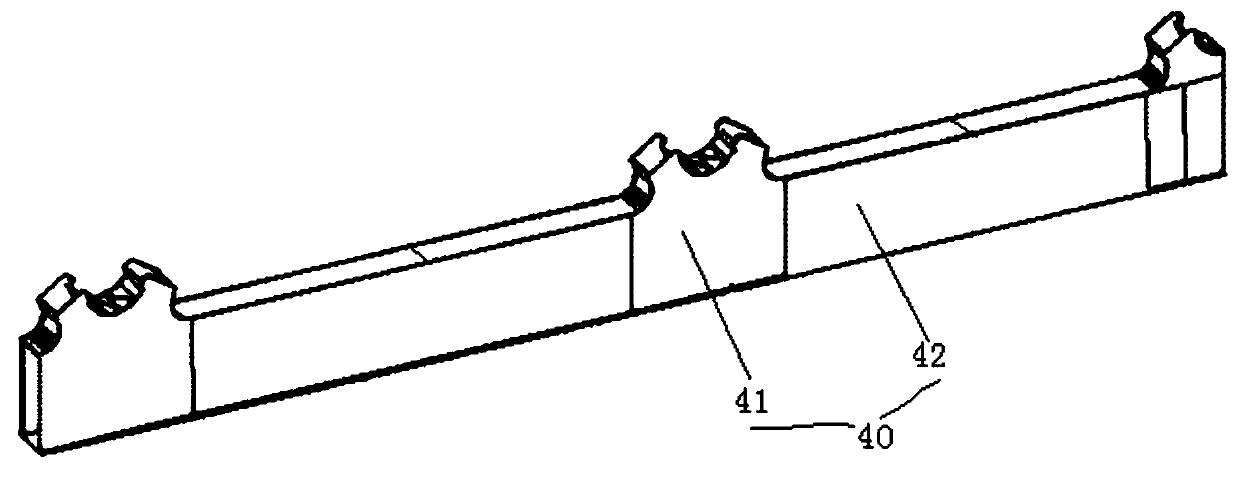

[0029] like Figure 1 to Figure 2 As shown, the invention provides a method for manufacturing a hyperbolic fully welded structural steel truss beam, comprising:

[0030] S1, set up the rod-assembled tire frame, which is used as the trial assembly model of the truss;

[0031] The trial assembly of the trusses in the factory is carried out on the special tire frame. During the assembly process, key points such as truss height, diagonal difference, camber, and plane alignment are strictly controlled. When the trusses are assembled, the matching between adjacent small segments is done to ensure that the bridge The position erection rods are accurately positioned and the steel truss girders are ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com