Friction energy dissipation sleeve reinforcing device and use method thereof

A reinforcement device and frictional energy consumption technology, which is applied in building maintenance, building components, building types, etc., to achieve the effect of improving bearing capacity, simple and effective reinforcement method, and flexible reinforcement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

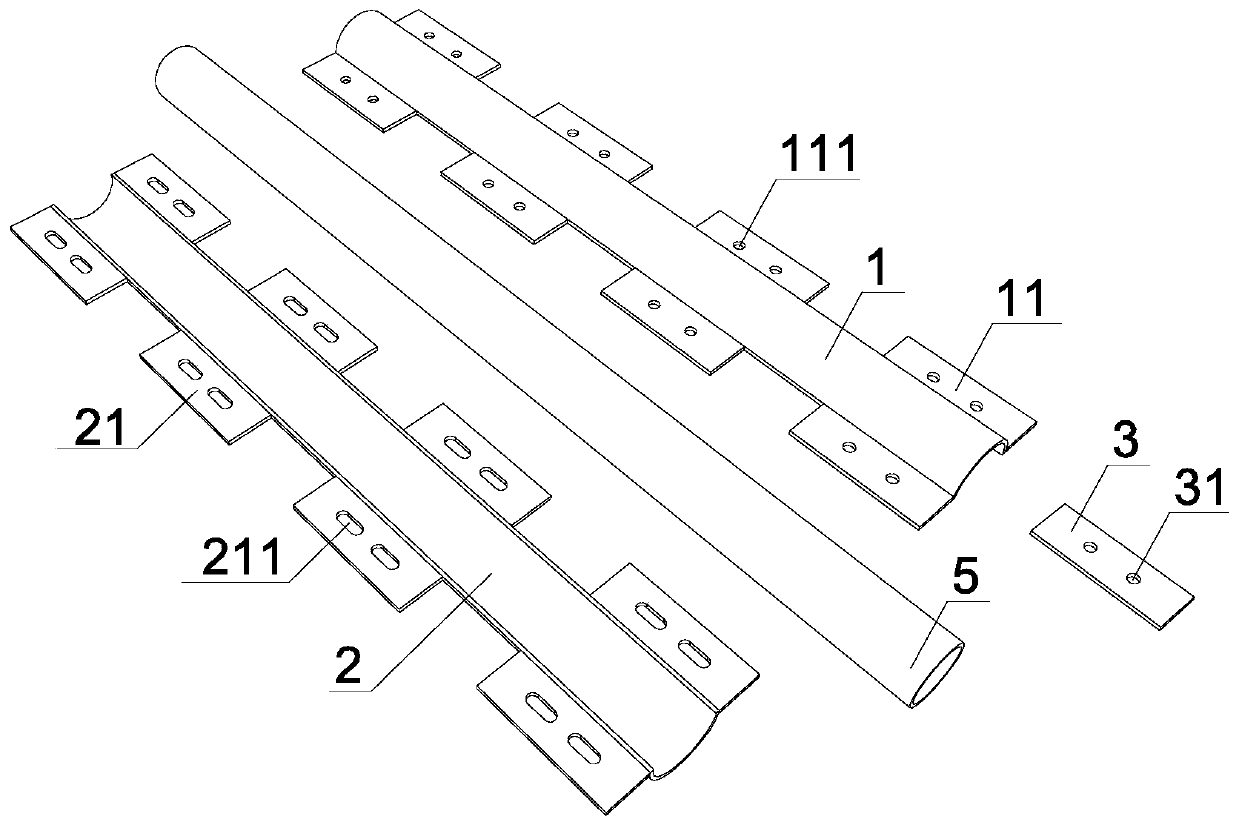

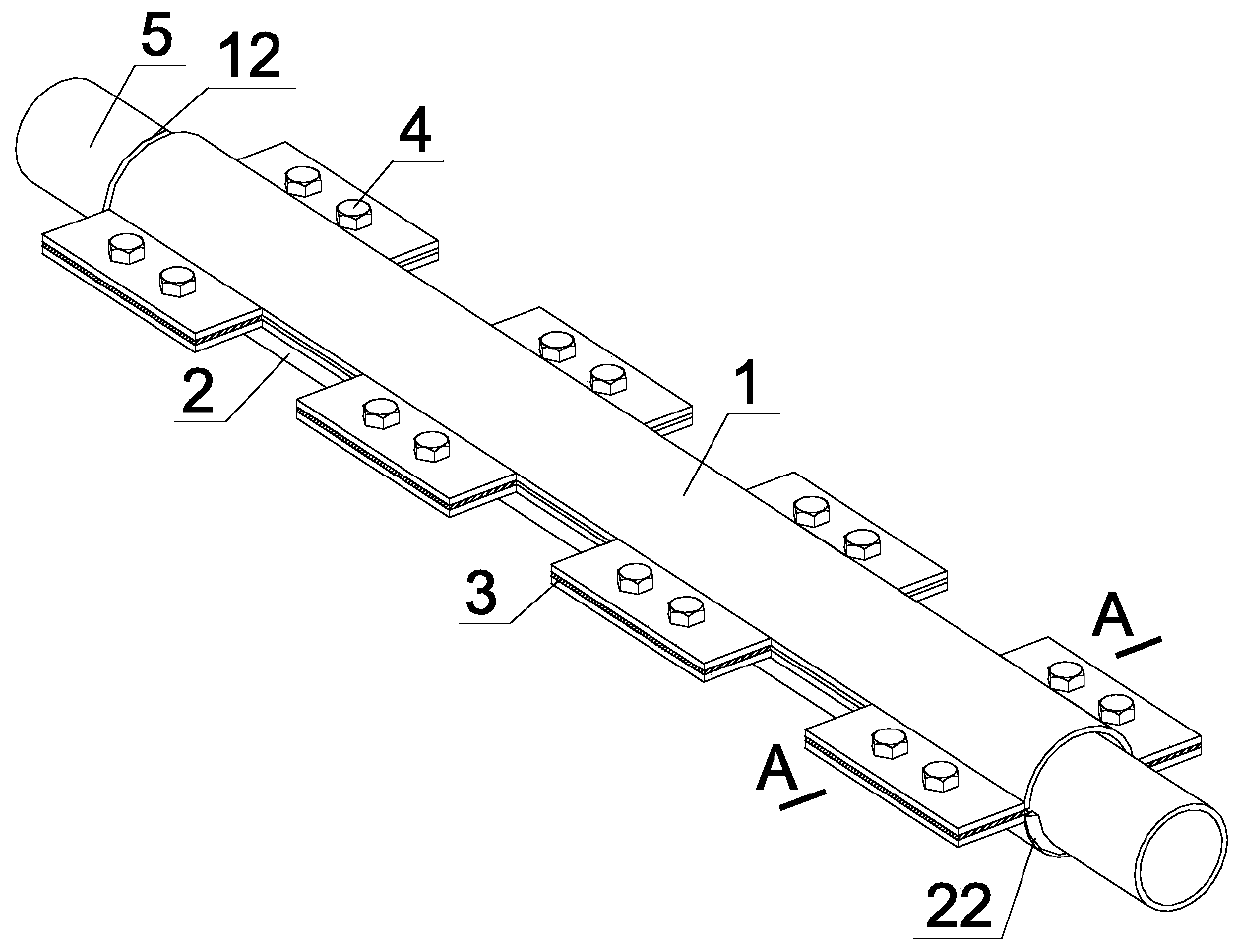

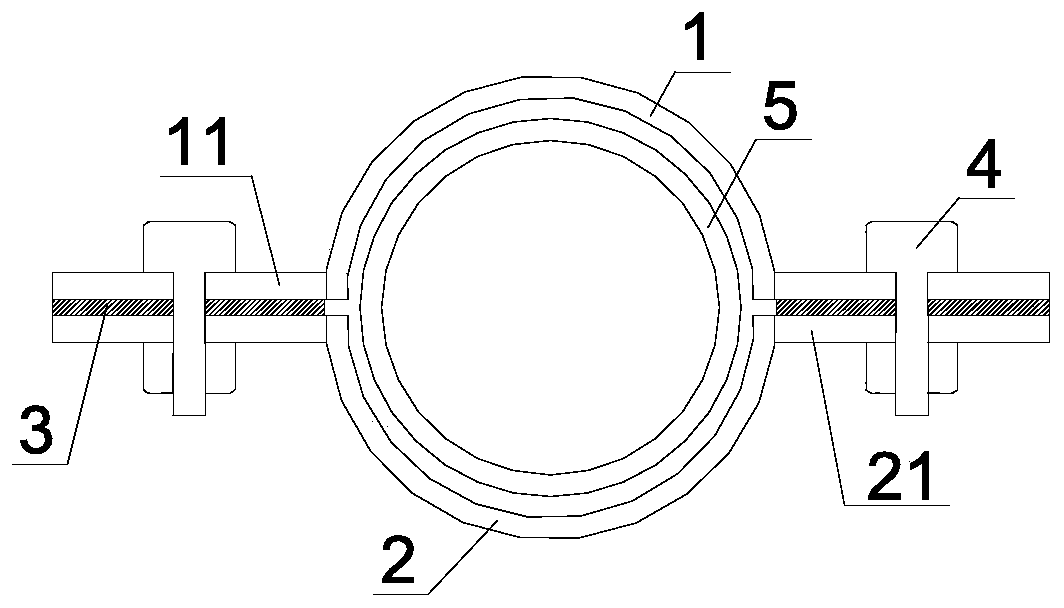

[0030] like Figure 1~3 , use the symmetrical first segment 1 and the second segment 2 to reinforce the pressure bar 5, the first segment 1 includes the first stiffening plate 11 which is evenly distributed along the length direction of the tube and fixedly connected, the first stiffening plate 11 has a circle Hole one 111, the second segment 2 includes second stiffening plates 21 uniformly distributed and fixedly connected along the length of the tube, and the second stiffening plate 21 has a slot one 211 along the length of the tube. The friction sheet 3 is clamped between the first stiffening plate 11 and the second stiffening plate 21. The size of the friction sheet 3 is not larger than the first stiffening plate 11. The friction sheet 3 is a copper sheet and has the same position and size as the round hole 111. Two circular holes 31 are arranged. Round hole 1 111, round hole 2 31 and slot hole 1 211 are fixed by bolts 4 to form the restraint part of the reinforcement bar...

Embodiment 2

[0032] like Figure 4 , This embodiment is the same as the rest of Embodiment 1, except that the first segment 1 and the second segment 2 of polygonal flaps are used, and the friction sheet 3 is non-asbestos organic matter.

Embodiment 3

[0034] like Figure 5 , This embodiment is the same as the rest of Embodiment 1, except that the reinforcement object is a compression bar 5 with an H-shaped steel section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com