Method for improving power generation efficiency of water turbine and inhibiting cavitation erosion of spare parts of water turbine

A technology of power generation efficiency and water turbines, applied in the fields of hydropower generation, machines/engines, engine components, etc., can solve the problems of complex design, erosion of water turbines, high prices, etc., and achieve the effect of suppressing cavitation, preventing cavitation, and increasing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Preferred embodiments are provided below for the above-mentioned technical features of the present invention; however, water turbines are of a great variety, and their shapes and structures are not exactly the same, so although only the preferred embodiments are listed for illustration, the technical means used are the same, Therefore, it is not possible to repeat them one by one. And the "hydraulic turbine spare parts" mentioned below include related components such as hydraulic turbine parts and accessories. Another rotating blade can also be called impeller or related names.

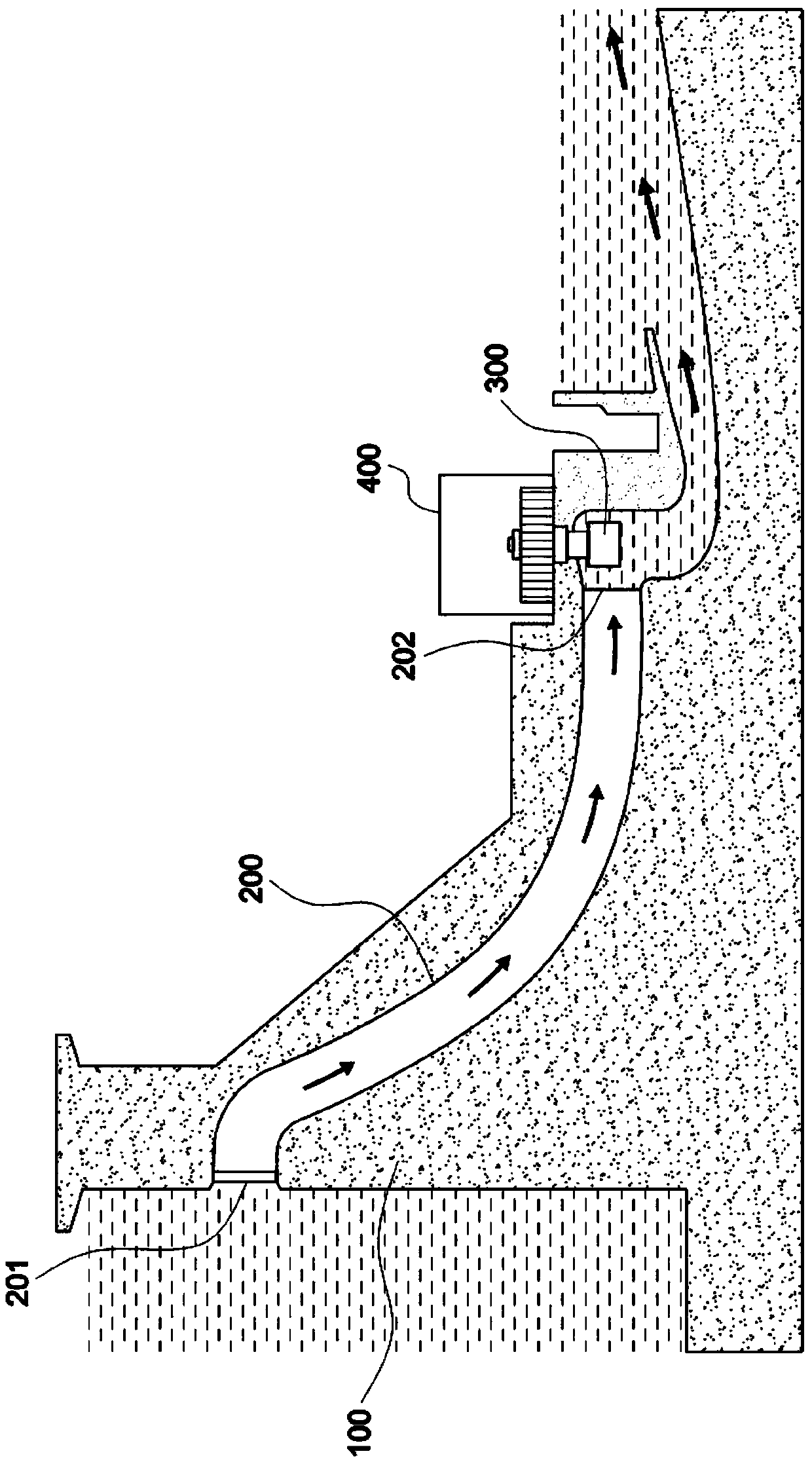

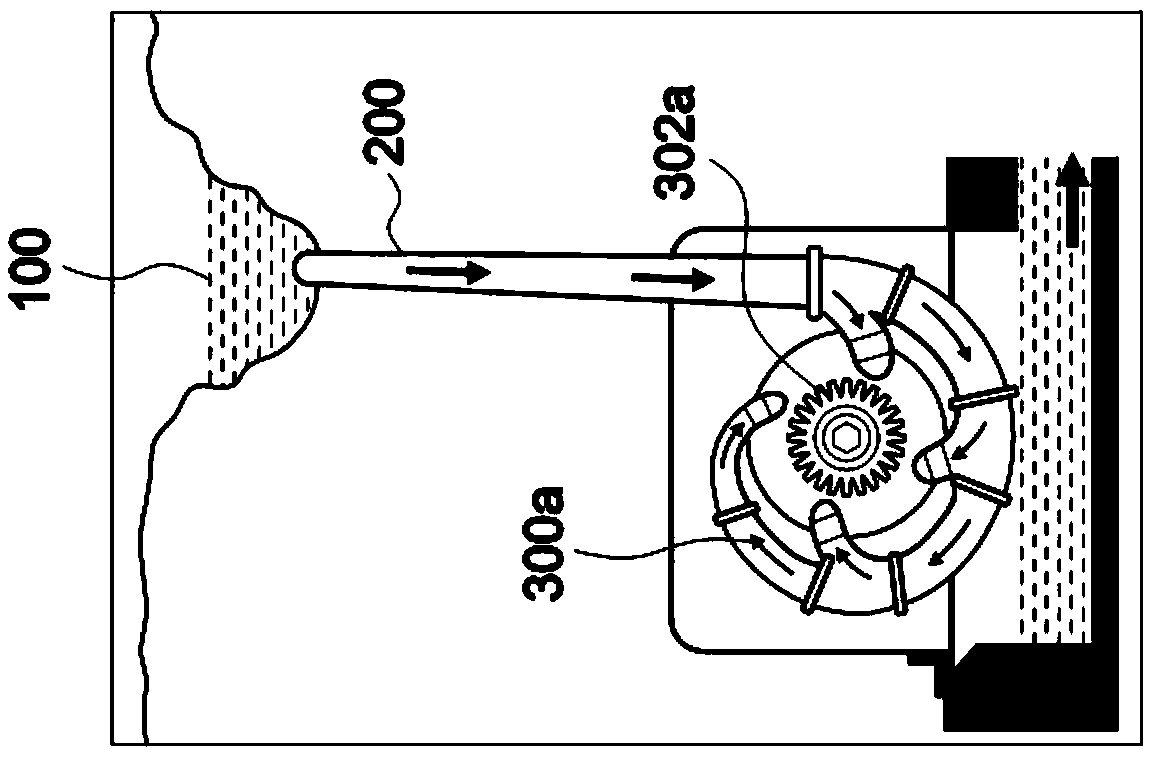

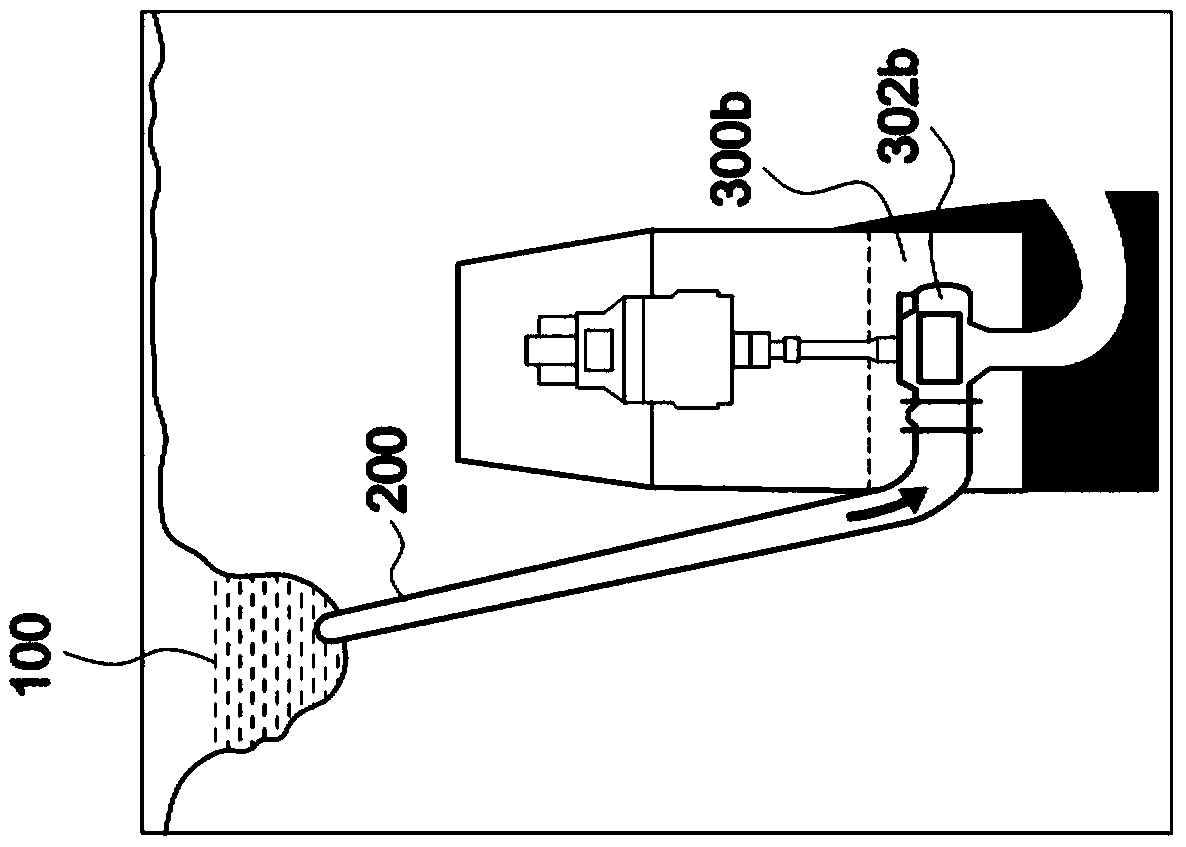

[0060] First, see Figure 3 to Figure 10 As shown, the first feasible embodiment of the present invention includes: a water diversion pipe 20 arranged on the dam 10 of the hydropower station, either inside or above the dam 10 . Its upper end has a water inlet 21, and the bottom end has a water outlet 22; The water outlet 22 utilizes the water diversion pipe 20 to drive the rotating blade 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com