A linear locking cylinder with a built-in fixed ultrasonic screw rod

An ultrasonic and fixed technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of complex structure and assembly, low positioning accuracy, poor sealing performance, etc., and achieve the effect of simple structure and assembly, high positioning accuracy, and solving the effect of reducing sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

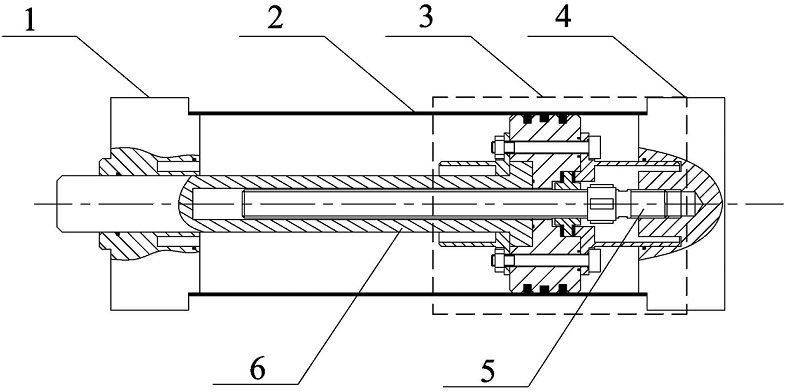

[0029] Embodiment 1: Combining Figure 1~Figure 12 Illustrating this embodiment, this embodiment provides a specific implementation of a linear locking cylinder with a built-in fixed ultrasonic screw rod. The specific implementation is described as follows:

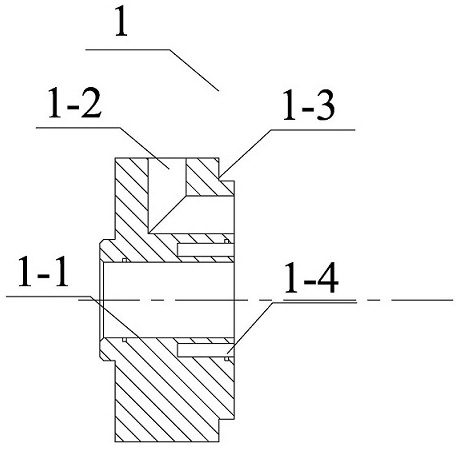

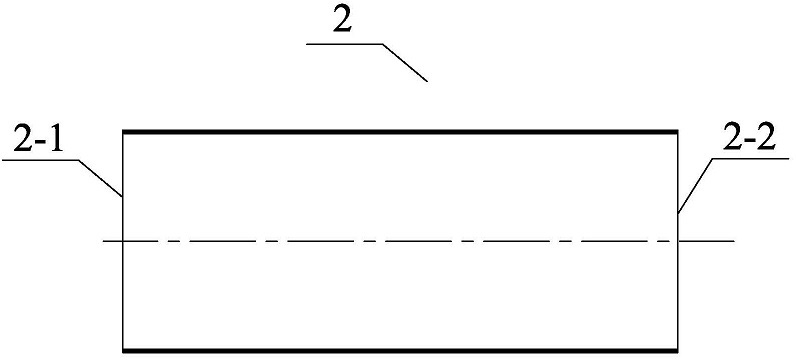

[0030] The linear locking cylinder with built-in fixed ultrasonic lead screw is composed of a front end cover 1 , a cylinder barrel 2 , a piston assembly 3 , a rear end cover 4 , an ultrasonic lead screw assembly 5 , and a piston rod 6 . One end of the cylinder barrel 2 is fastened with the front end cover 1, and the other end is connected with the rear end cover 4 by threaded connection. One end of the ultrasonic screw assembly 5 is connected with the rear end cover 4 by means of threads, and the other end passes through the piston assembly 3 and then is sleeved into the piston rod 6. The piston rod 6 is fixed on the piston assembly 3 and passes through the front end. The cover 1 and the piston assembly 3 can realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com