A silicon micromachined gyroscope with a four-column mass

A technology of silicon micromachines and quality blocks, which is applied to gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., can solve the problems of limiting gyroscope detection signal and sensitivity, high detection frequency, etc., and reduce output noise signal, improve the signal-to-noise ratio, and improve the effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

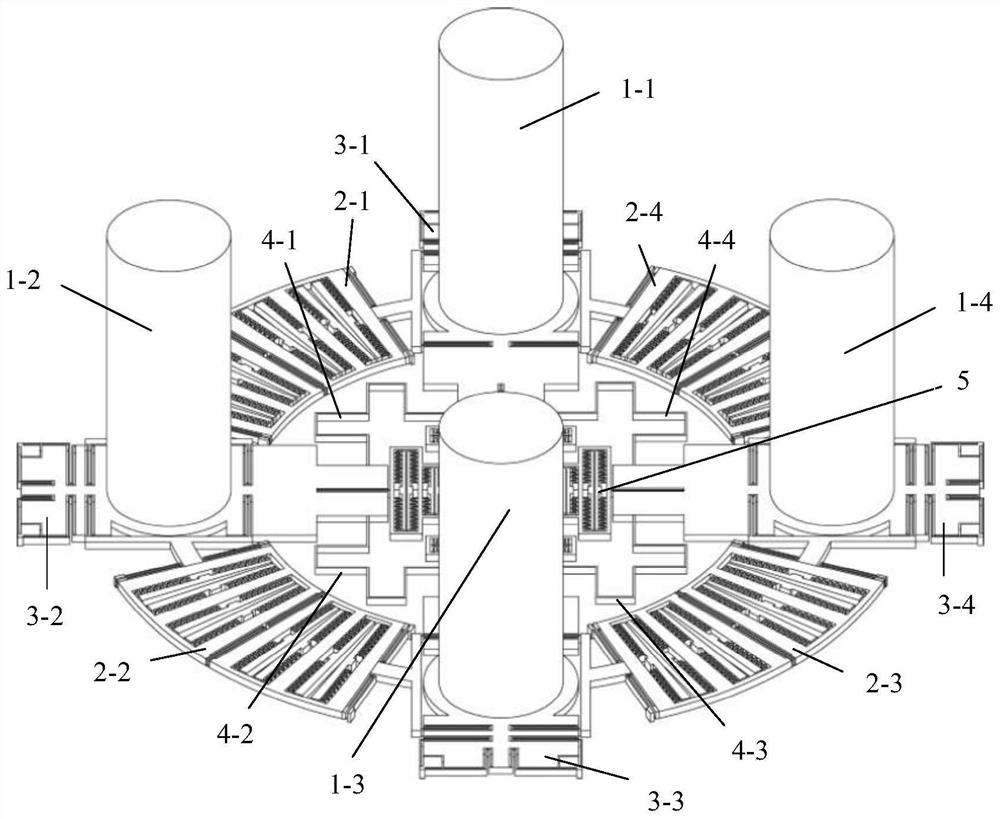

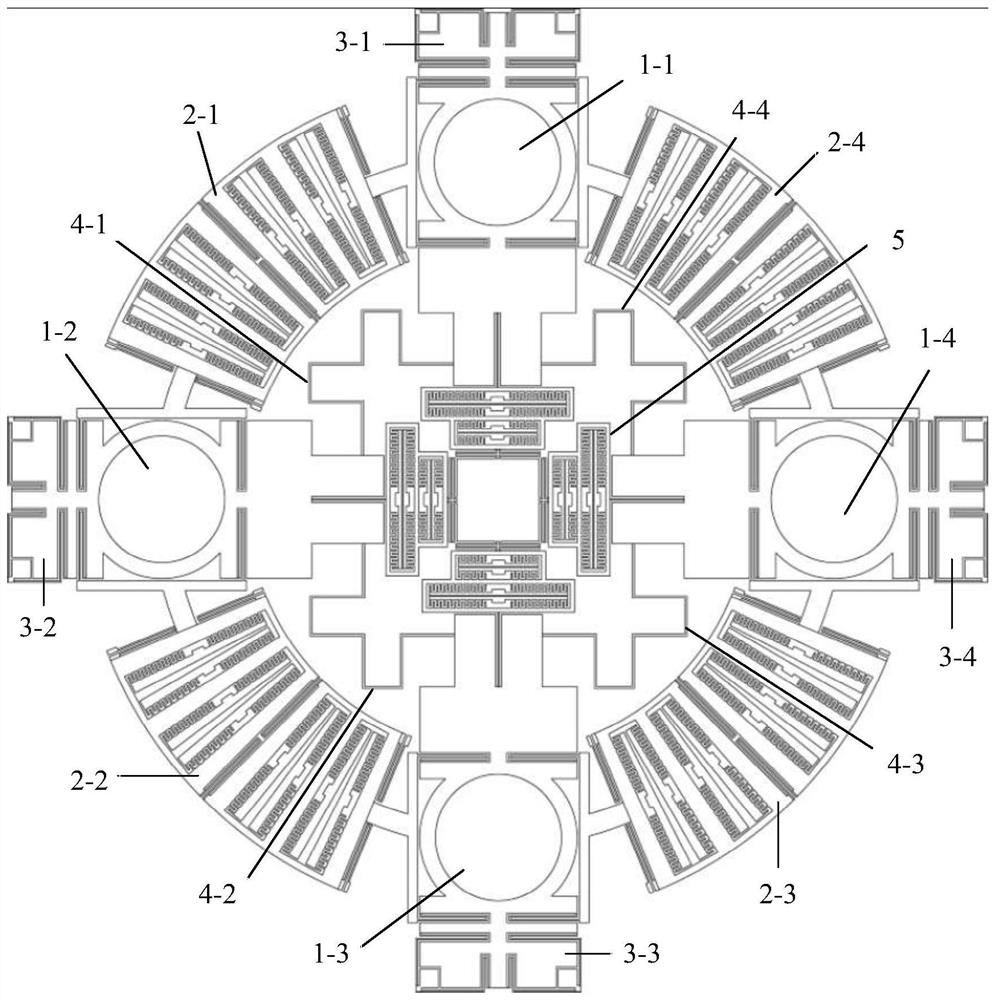

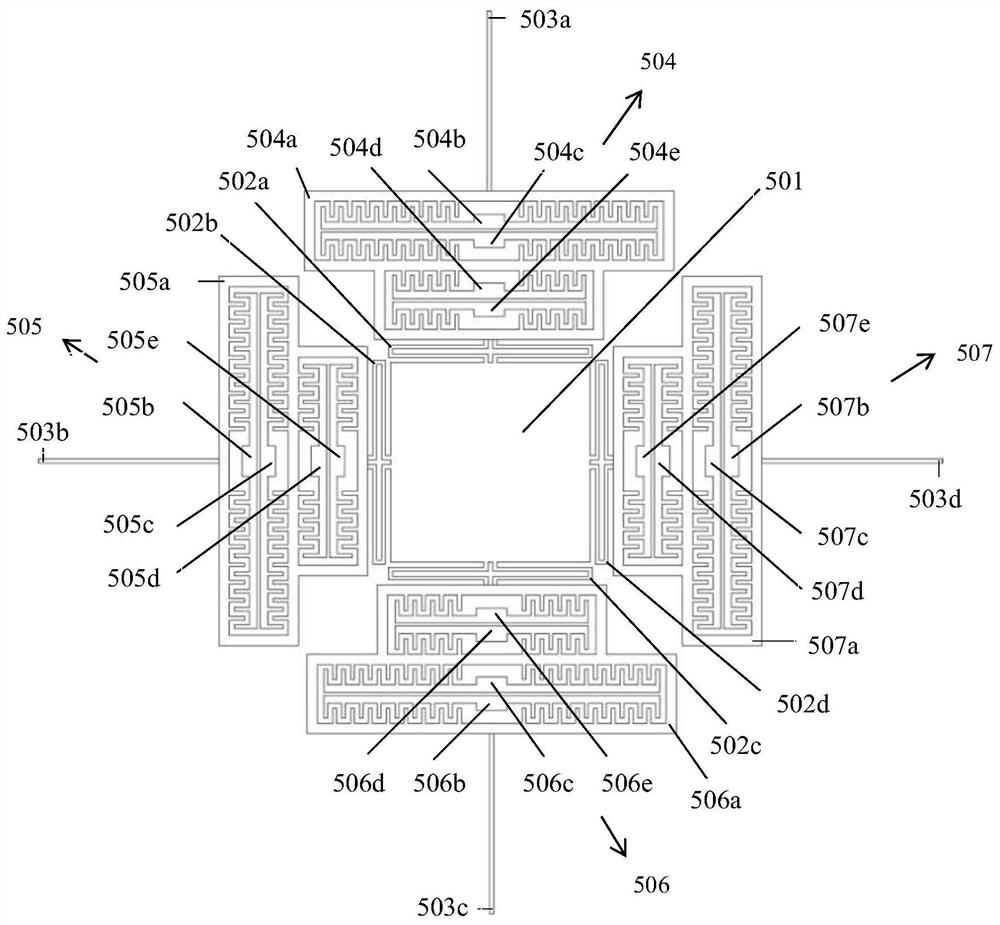

[0031] The silicon micromechanical gyroscope with a four-column-shaped quality block that can realize vertical axis angular velocity sensitivity provided by the present invention, such as figure 1 with figure 2 As shown, it includes upper, middle and lower three-layer structures, wherein the upper layer is four cylindrical mass blocks, the middle layer is a silicon microsensor structure, and the lower layer is a boron-based glass substrate with electrode leads. Cylindrical mass blocks 1-1, 1-2, 1-3, 1-4 are arranged in the center of the four mass block trays in the middle layer silicon microsensor structure, and materials such as SU-8 / silicon / structural steel al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com