Thread transmission mechanism and electric valve containing thread transmission mechanism

A thread transmission and electric valve technology, applied in the direction of engine components, lift valves, valve details, etc., can solve the problems of difficult assembly and low thread accuracy, achieve stable rotation, ensure position accuracy and strength, and avoid excessive contact length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

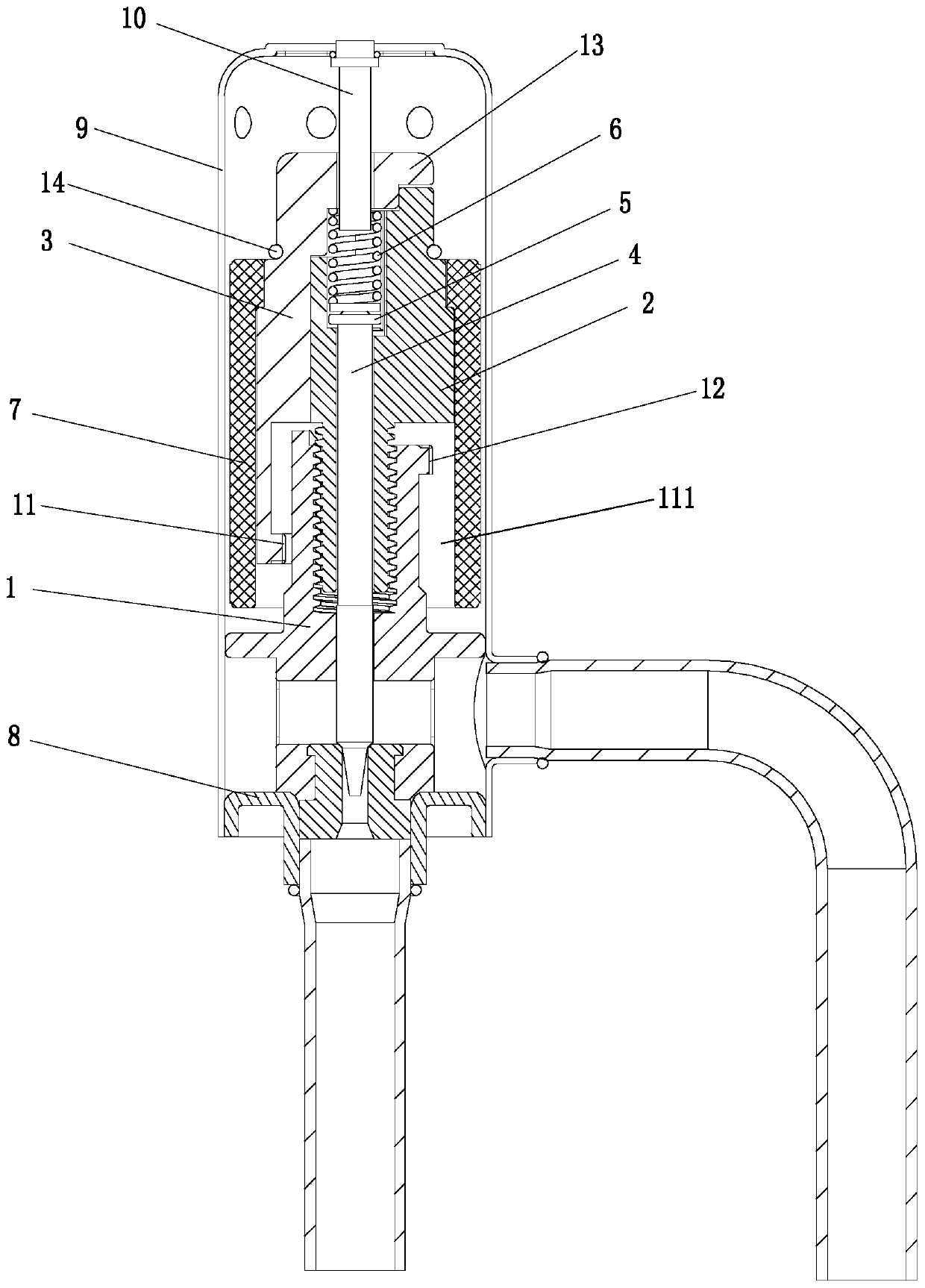

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

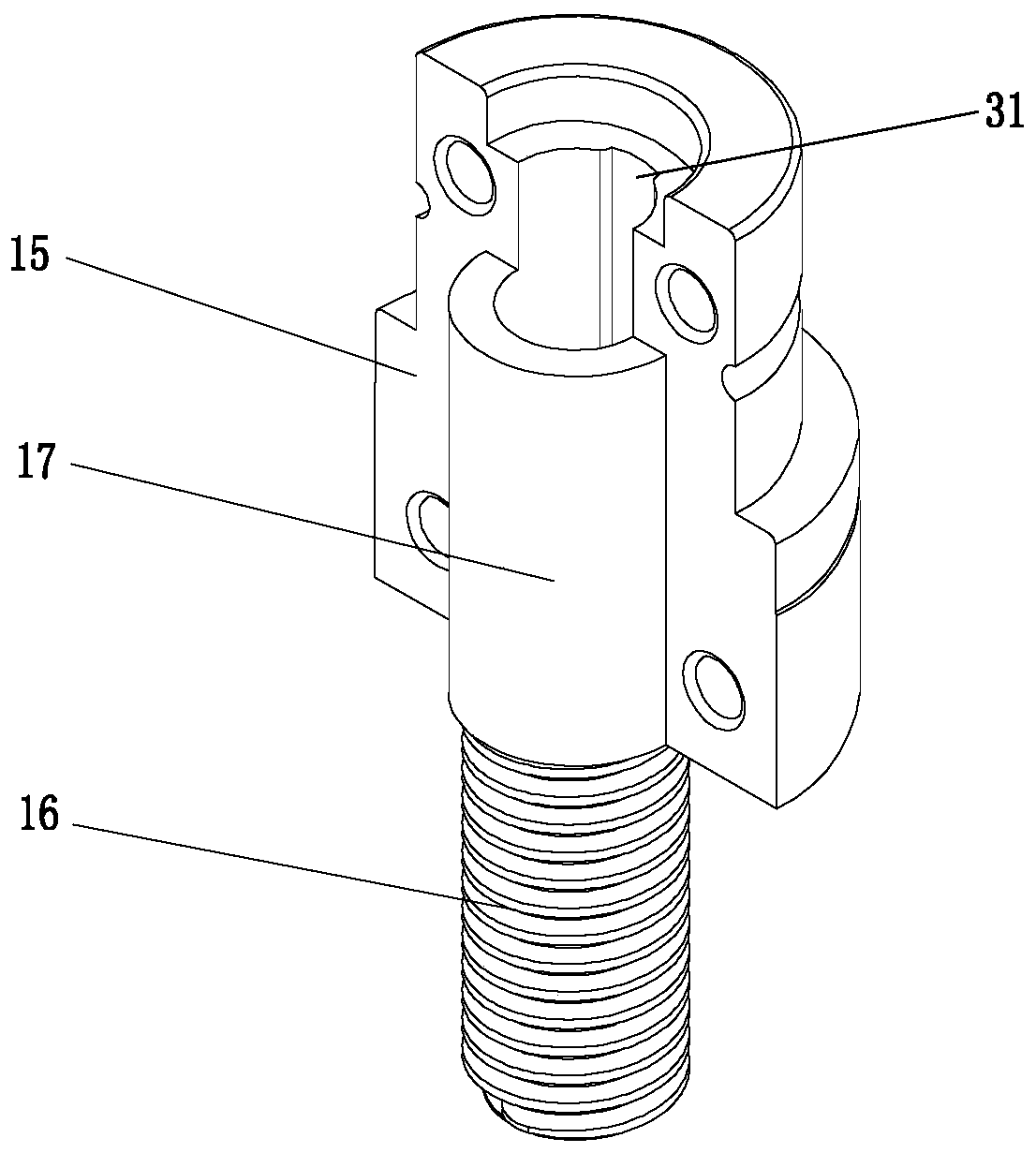

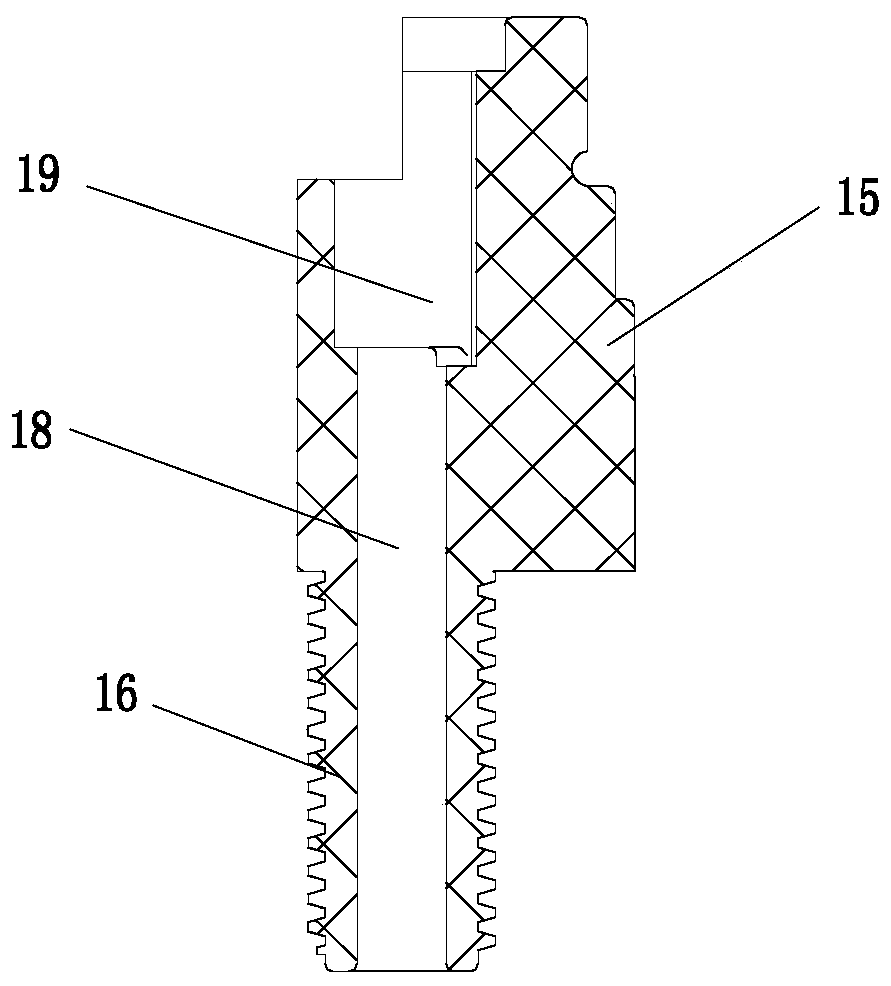

[0023] Such as Figure 1-Figure 4 As shown, the electric valve screw transmission mechanism of the present invention includes an internal thread part 1 and an external thread part. It includes a stepped semi-cylindrical base 15 and an externally threaded rod 16, the externally threaded rod 16 is fixedly connected to the bottom of the base, and the mounting seat 3 and the base 15 are in a stepped semi-cylindrical shape that cooperates with each other; the lower part of the mounting seat 3 and the base 15 cooperate to form a The motor rotor 7 of the electric valve is connected to the matching transmission part. A semi-cylindrical part 17 integrally formed with the external threaded rod is formed on the axial plane part of the base part 15. A semicircular groove matching the semi-cylindrical part 17 is formed on the mounting seat 3. .

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com