Coaxial direct-drive type electronic parking actuator

An electronic parking and actuator technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of large output torque, inaccurate positioning, low efficiency, etc., to improve efficiency and life, solve the problem of application Sexual problems, the effect of reducing work noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

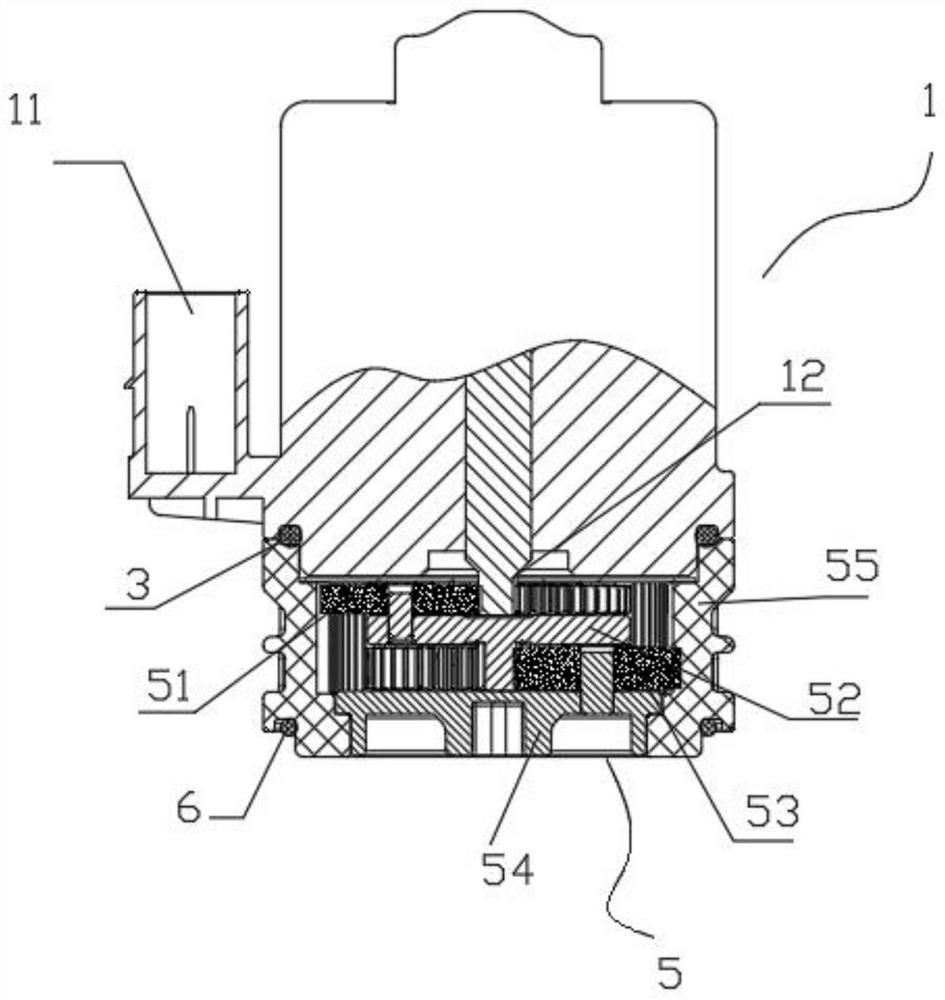

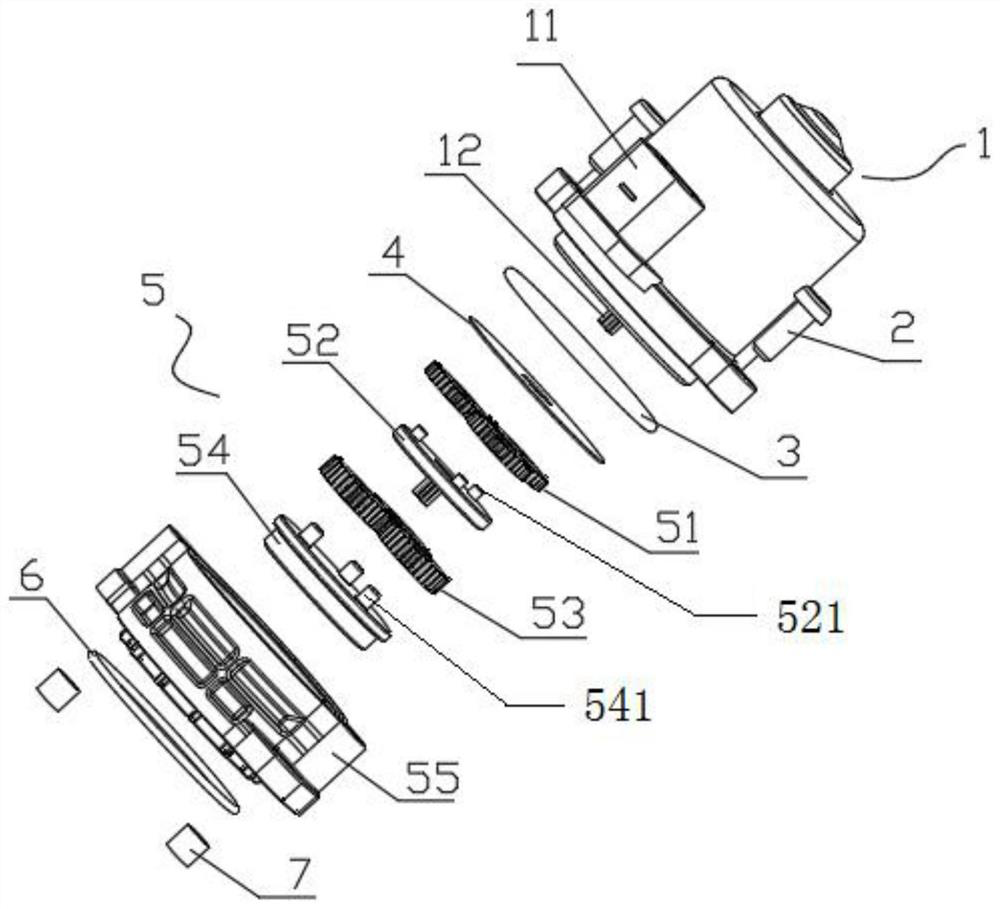

[0030] combine Figure 1-4 This embodiment provides a coaxial direct drive electronic parking actuator, including a motor 1 and a gearbox 5, the motor 1 is fixedly connected to the gearbox 5 and its axis coincides; the outer side of the motor 1 housing A connection part 11 is provided, and an insulating layer is arranged inside the connection part 11, and the wire harness connected to the wiring terminal of the internal motor of the motor 1 can be installed in the connection part 11 to prevent the occurrence of electric connection, and the The connection part 11 and the motor 1 are integrally formed by casting aluminum or stamping, and its compact structure does not require secondary assembly. The integral formation makes the motor 1 have good water resistance, and the overall equipment is safer.

[0031] The motor shaft gear 12 is fixedly connected to the power output end of the motor 1, and the motor shaft gear 12 is integrally formed with the shaft of the motor 1 to improve...

Embodiment 2

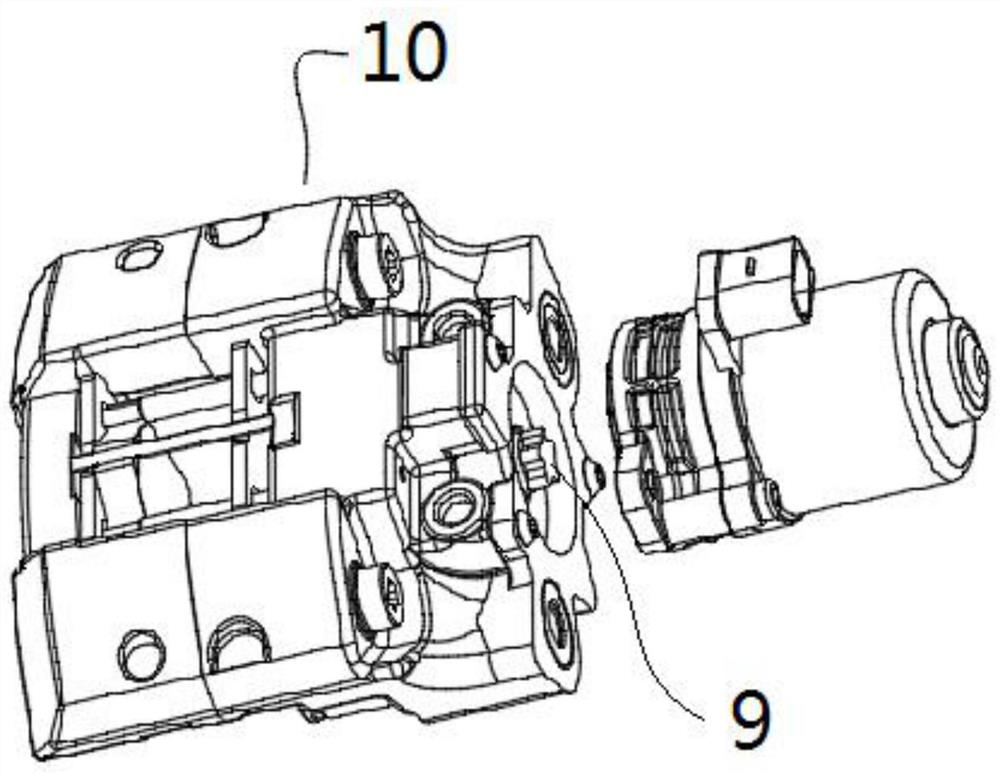

[0038] The difference between embodiment 2 and embodiment 1 is that both the internal spline 8 and the external spline 9 use a six-tooth spline, and the internal spline 8 and the output disc 54 are integrally formed without secondary splines. Processing improves the connection strength between the internal spline 8 and the output disc 54 and ensures the concentricity of the internal spline 8 and the output disc 54 .

[0039] The motor 1 adopts a flat motor, and the selection of the flat motor makes the axial length of the motor 1 smaller when the output power is the same, so that the volume of the parking device is smaller and the application range is wider.

[0040] The first-stage gear 51 and the second-stage gear 53 are formed by metal powder metallurgy or metal sheet extrusion, thereby reducing the height of the gear box 5 and reducing the overall volume of the device, increasing the range of use.

[0041] In this embodiment, the number of teeth of the internal gear ring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com