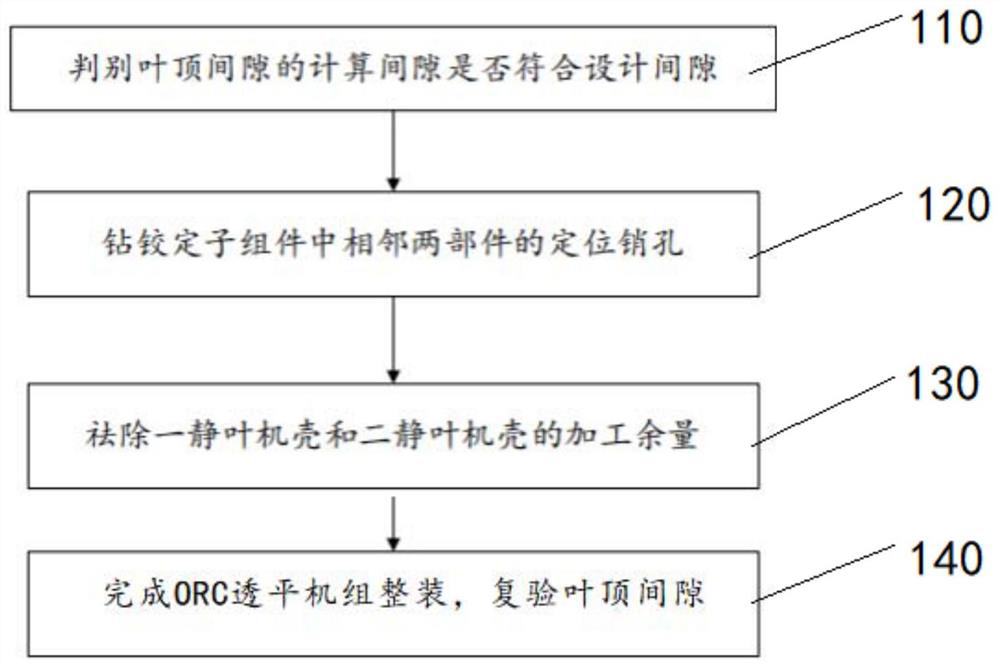

Method for controlling blade top clearance of ORC (organic Rankine cycle) turbine unit

A technology of blade tip clearance and turbine unit, which is applied in the field of compressors, can solve the problems of inability to meet the needs of industrial production and low assembly efficiency of ORC turbine units, and achieve the effects of increasing productivity, reducing work intensity, and ensuring the installation pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

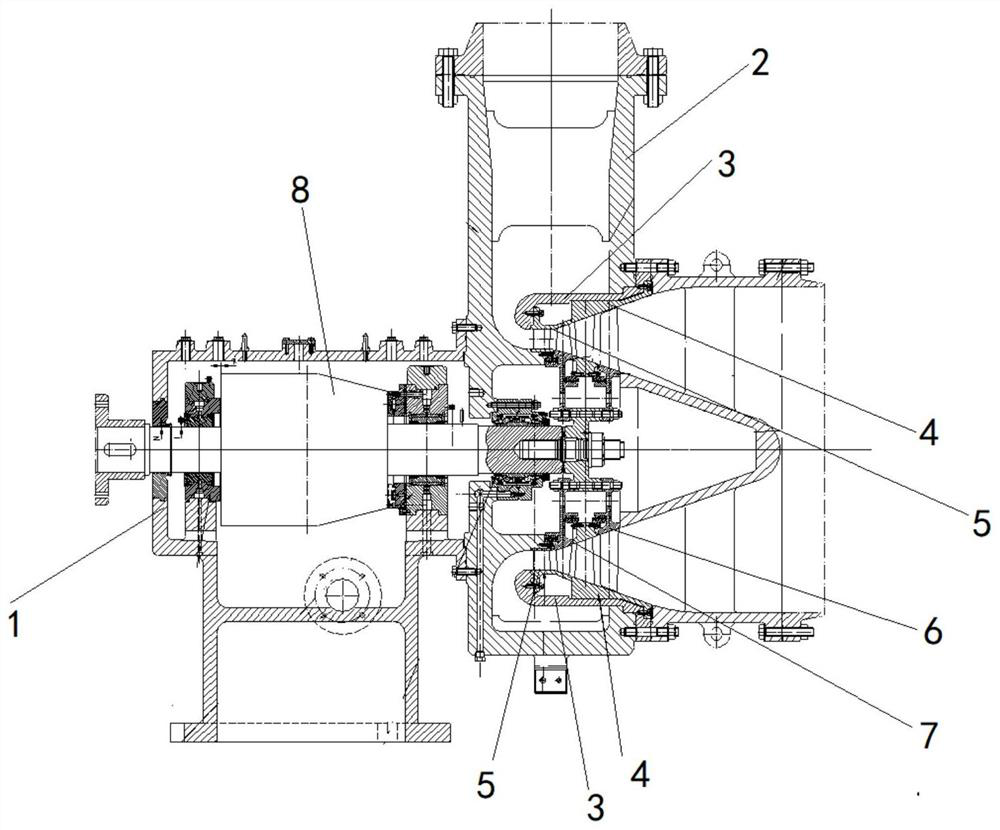

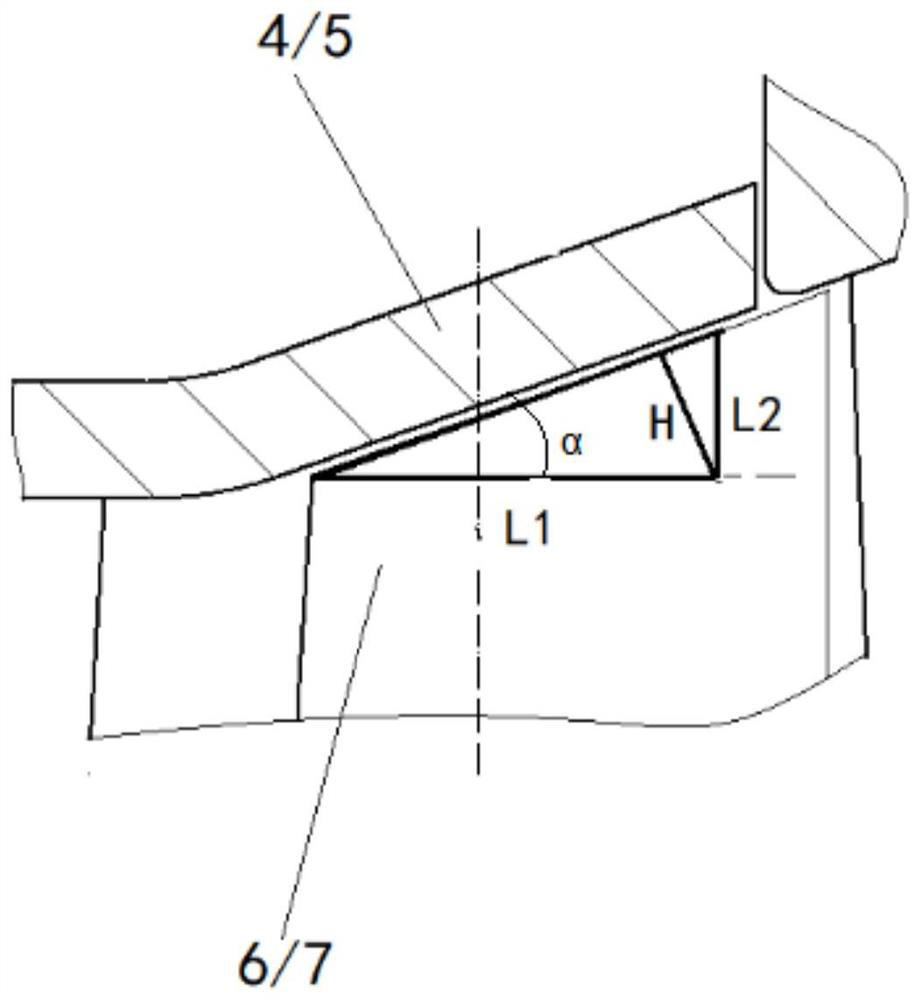

[0057] In the present invention, if figure 1 As shown, the ORC turbine unit includes a bearing box, an intake volute, a guide casing, a stator assembly composed of a first-stage stator casing and a second-stage stator casing, and a main shaft, a first-stage blisk, and a second-stage blade A rotor assembly composed of discs, the rotor assembly is set in the stator assembly. Wherein, the tip clearance is the gap between the top of the first-stage blisk and the casing of the first-stage stator, and the gap between the top of the second-stage blisk and the casing of the second-stage stator.

[0058] As the background technology, at present, when the ORC turbine unit is assembled, in order to ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com