Anti-freezing system and method for zero-power operation air cooling island of low-pressure cylinder of direct air cooling unit

An air-cooling unit and anti-freezing system technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of freeze-damaged air-cooling island and insufficient heat load of air-cooling island, so as to avoid freezing damage and internal freezing damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

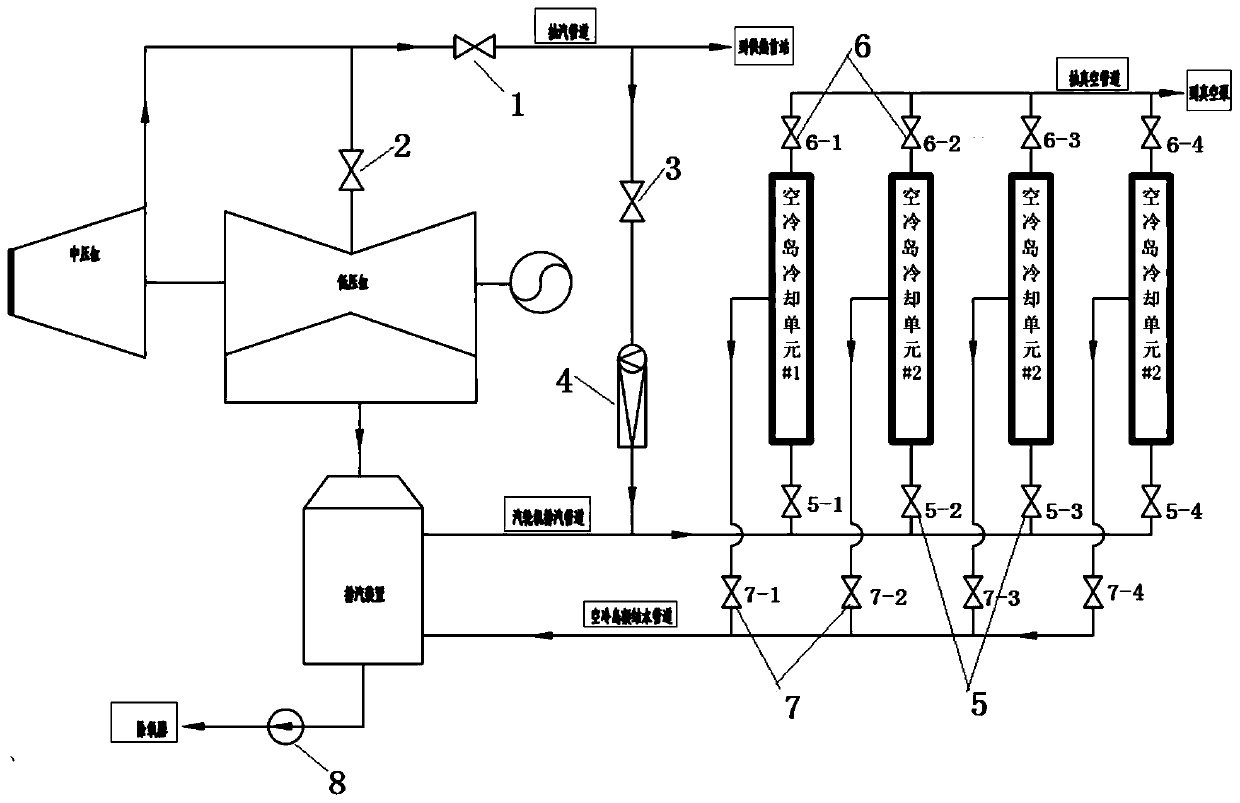

[0033] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, the air-cooling island antifreeze system of the low-pressure cylinder of the direct air-cooling unit operates at zero power, including a steam turbine, an exhaust device, and an air-cooling island connected in sequence. A branch of the steam output pipeline of the steam turbine is connected to the low-pressure cylinder of the steam turbine through the second valve group 2 At the gas inlet end, the other branch of the steam pipeline output by the steam turbine is connected to the air-cooling island through the third valve group 3 and the desuperheater 4 connected in series, and the desuperheater 4 is connected to the air-cooling island according to the set demand of the air-cooling island The amount of steam and the ambient temperature control the amount of steam delivered to the air-cooled island.

[0034] Optionally, as an achievable structure, the steam turbine can be a primary...

Embodiment 2

[0044] The present disclosure provides an antifreeze control method based on the low-pressure cylinder of the direct air-cooled unit low-power operation air-cooled island antifreeze system described in Embodiment 1, including the following steps:

[0045] Obtain the operating status of the low pressure cylinder of the direct air cooling unit;

[0046] When the low-pressure cylinder of the direct air-cooling unit is in the zero-power operating state, the third valve group 3 is closed, and the decompression and desuperheater 4 is started;

[0047] Obtain user configuration data, the configuration data including the number of air-cooled island cooling units put into operation and the antifreeze flow rate of a single air-cooled island cooling unit;

[0048] The required steam flow is calculated according to the configuration data, and the steam flow entering the air cooling island is controlled according to the required steam flow.

[0049] As an implementation method, the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com