Circulating cooling water device applied to petroleum driller braking system and application method

A technology of circulating cooling water and brake system, which is applied in the direction of mechanical equipment, brake parts, slack regulator, etc., can solve the problems of increased engineering quantity, electric heater corrosion and leakage, pollution and safety, etc., to improve cooling efficiency, Effect of improved cooling efficiency and no pollution cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

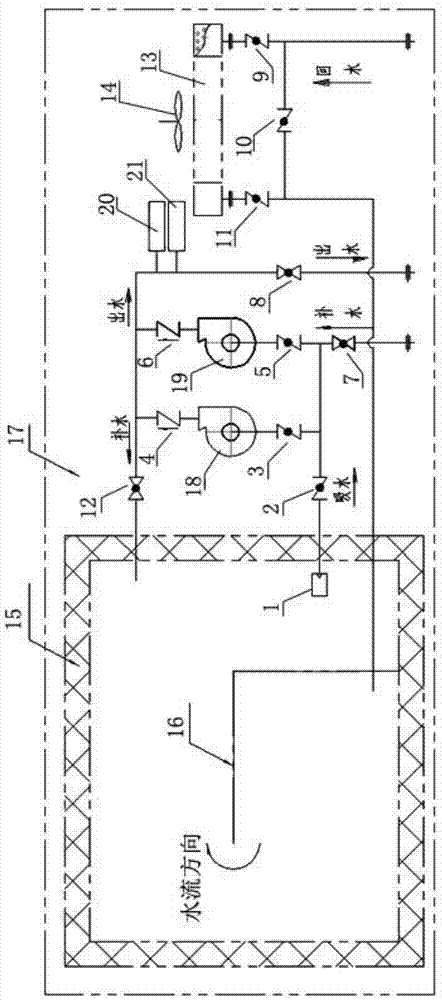

[0055] See figure 1 , suitable for oil drilling rigs of ZJ90 and below models. It is composed of a water storage tank, a water pump, a cooler 13, pipelines, valve control components, and a temperature control system.

[0056] Parameters of each component in this embodiment:

[0057] The volume of the water storage tank is 40m 3 ;

[0058] Water pump (pump A18 or pump B19) flow rate 50m 3 / h, head 50m, 2 water pumps, explosion-proof type;

[0059] Cooling fan air volume 67892m 3 / h, wind pressure 415Pa, explosion-proof type;

[0060] Applicable ambient temperature range: -25℃~50℃.

[0061] This embodiment requires a field test and a trial stage, and can be put into normal use afterwards. Do no-load water circulation test in the test stage, operate according to the use steps in the trial stage, determine the lower limit and upper limit of temperature control according to the actual situation, find out the best setting value, and make the device operate in the best state....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com