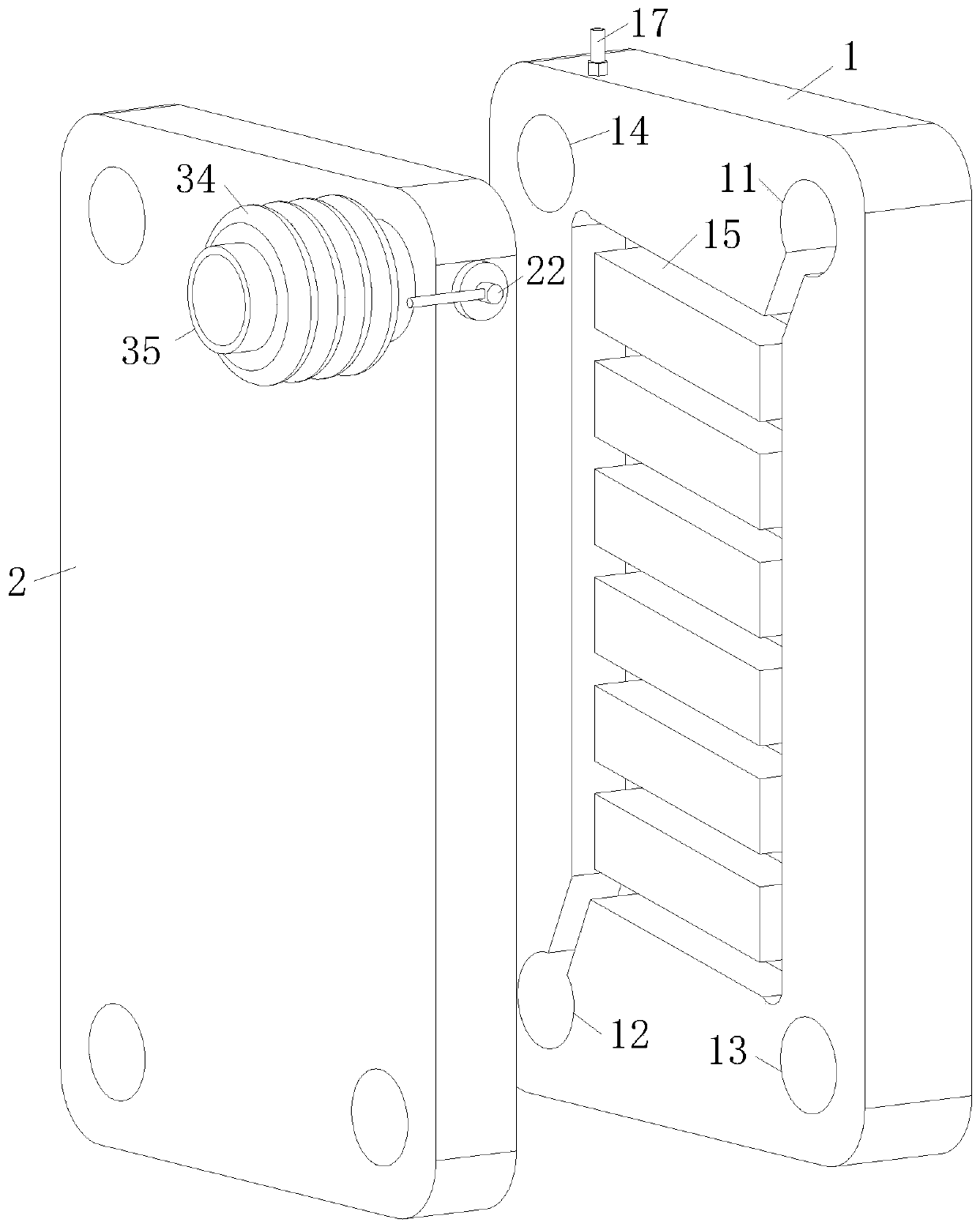

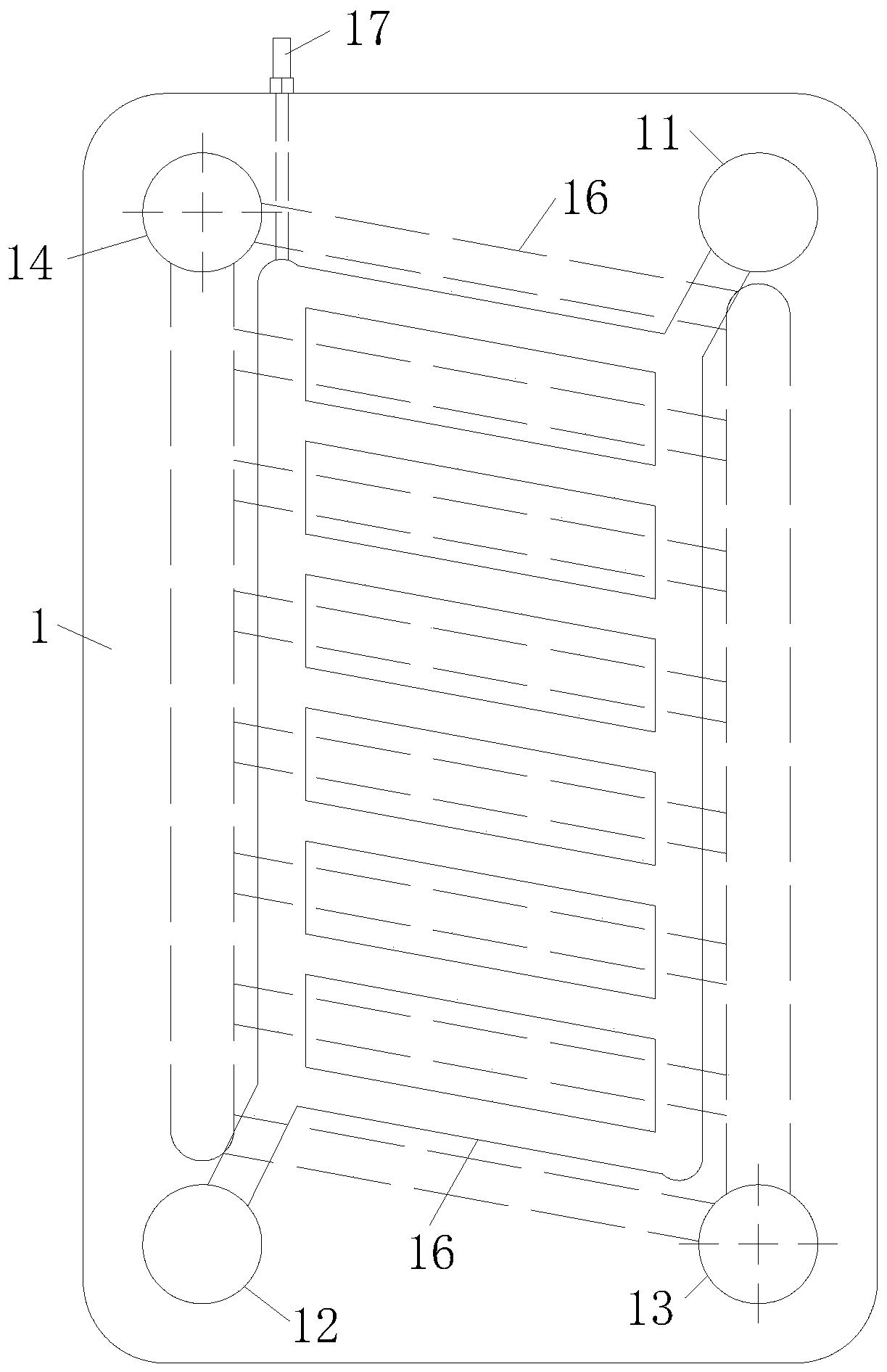

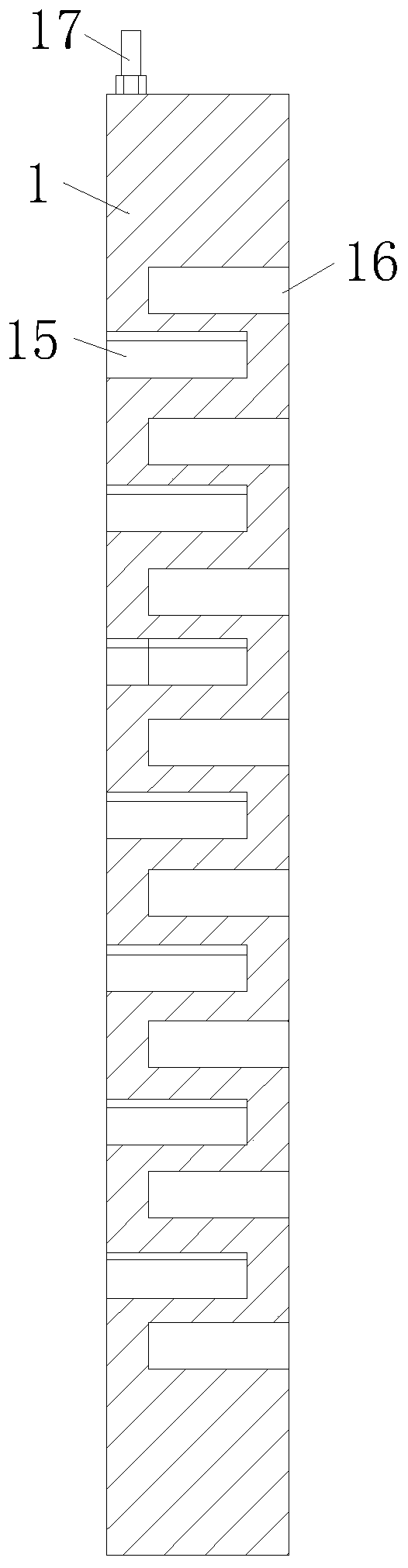

Plate heat exchanger

A technology of plate heat exchanger and heat exchange plate, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Affect the heat transfer efficiency of the heat medium and other issues, to achieve the effect of increasing the efficiency, increasing the vibration effect, and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] As an embodiment of the present invention, the side of the No. 1 branch pipe 23 close to the three-way valve 22 is provided with an arc-shaped guide plate 29. The guide plate 29 is used to gather the heat medium in the No. 1 branch pipe 23 and increase the flow rate of the water wheel 26. speed, to further increase the heat exchange efficiency of the heat exchange plate 1; through the arc-shaped guide plate 29, the heat medium is guided to collect and impact the blades 27 on the outer periphery of the water wheel 26, and at the same time reduce the flow of the heat medium through the bottom of the rotating chamber 25, thereby increasing the flow time of the heat medium The efficiency of promoting the rotation of the water wheel 26 further increases the speed of the water wheel 26, increases the vibration effect of the water wheel 26, further increases the discharge efficiency of the air bubbles in the heat medium channel 15, and finally further increases the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com