Three-dimensional shape sensing monitoring method and system based on multi-core optical fiber

A multi-core optical fiber and three-dimensional shape technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not being able to truly and accurately reflect the three-dimensional shape vector change of the structure, temperature cross-sensitivity, and difficult layout, etc., and achieve light weight , small environmental impact, the effect of suppressing the interference of ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

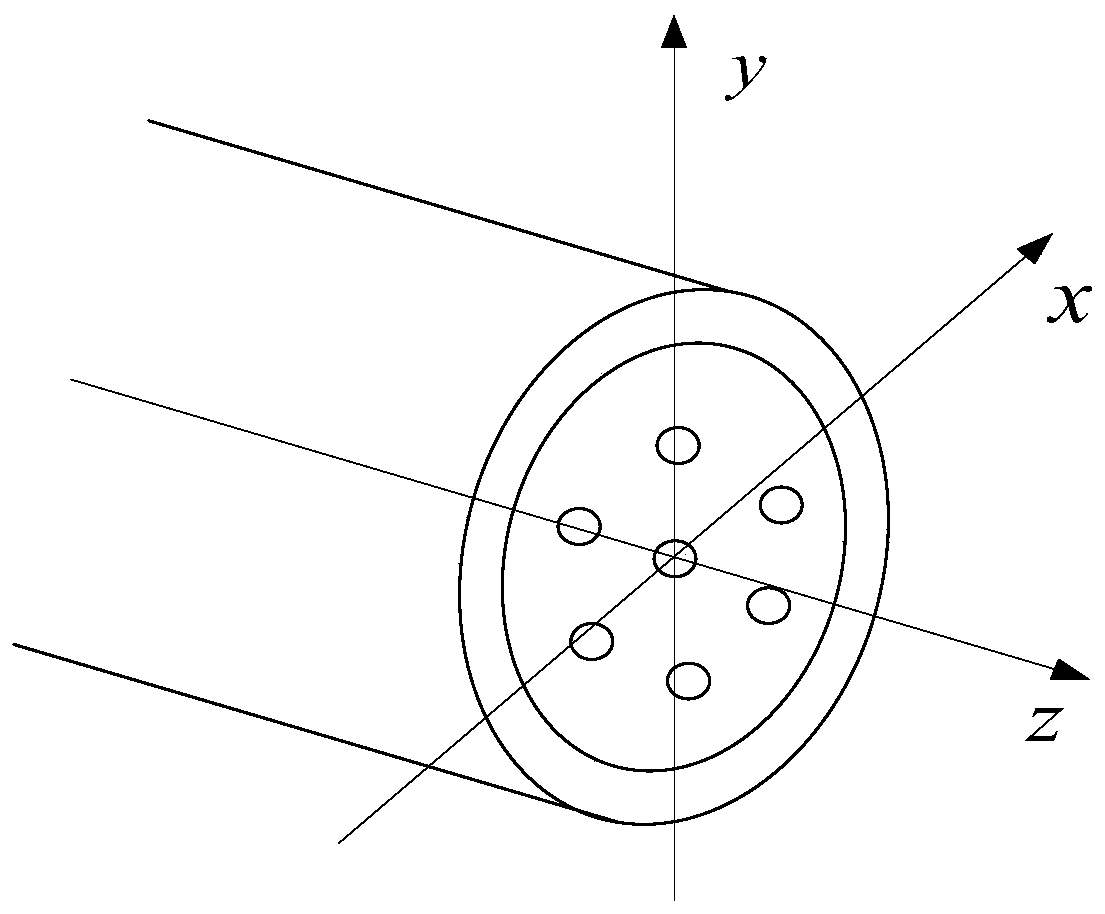

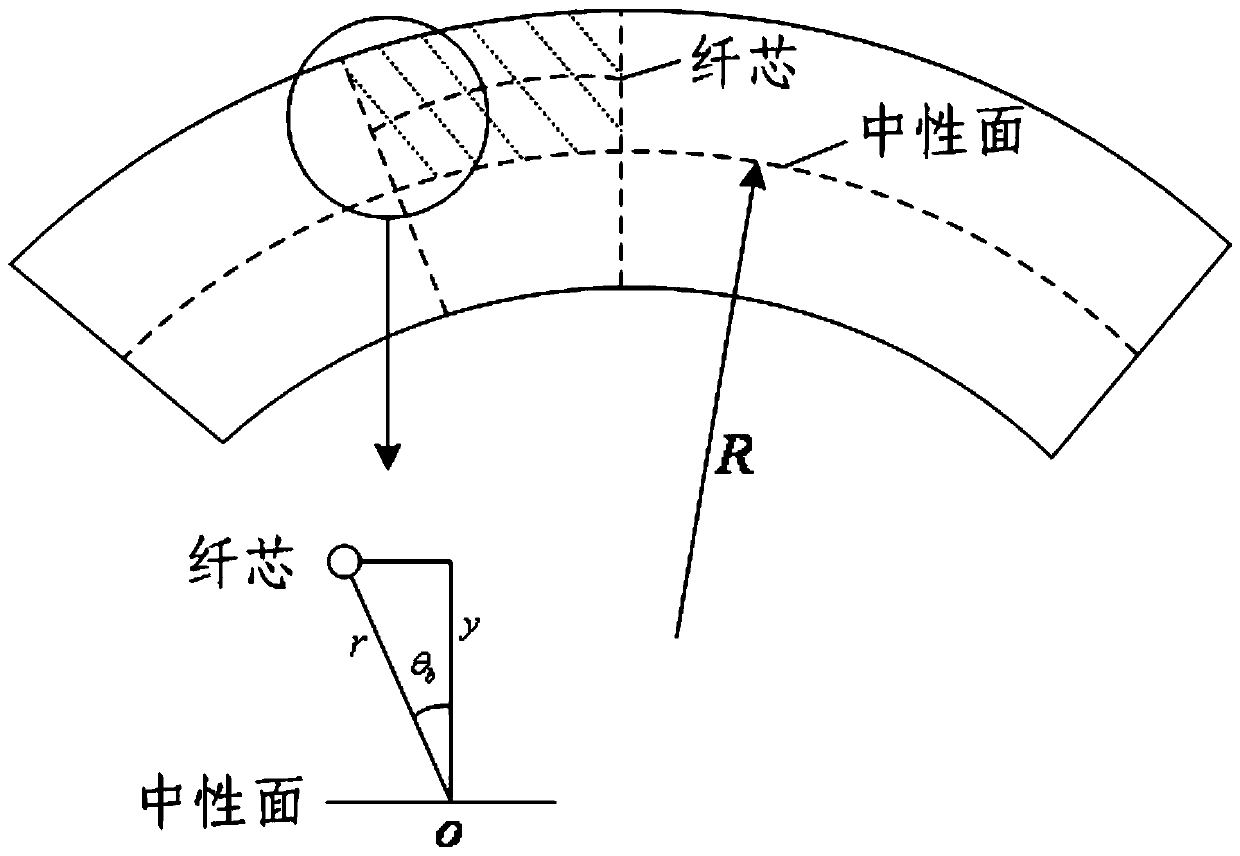

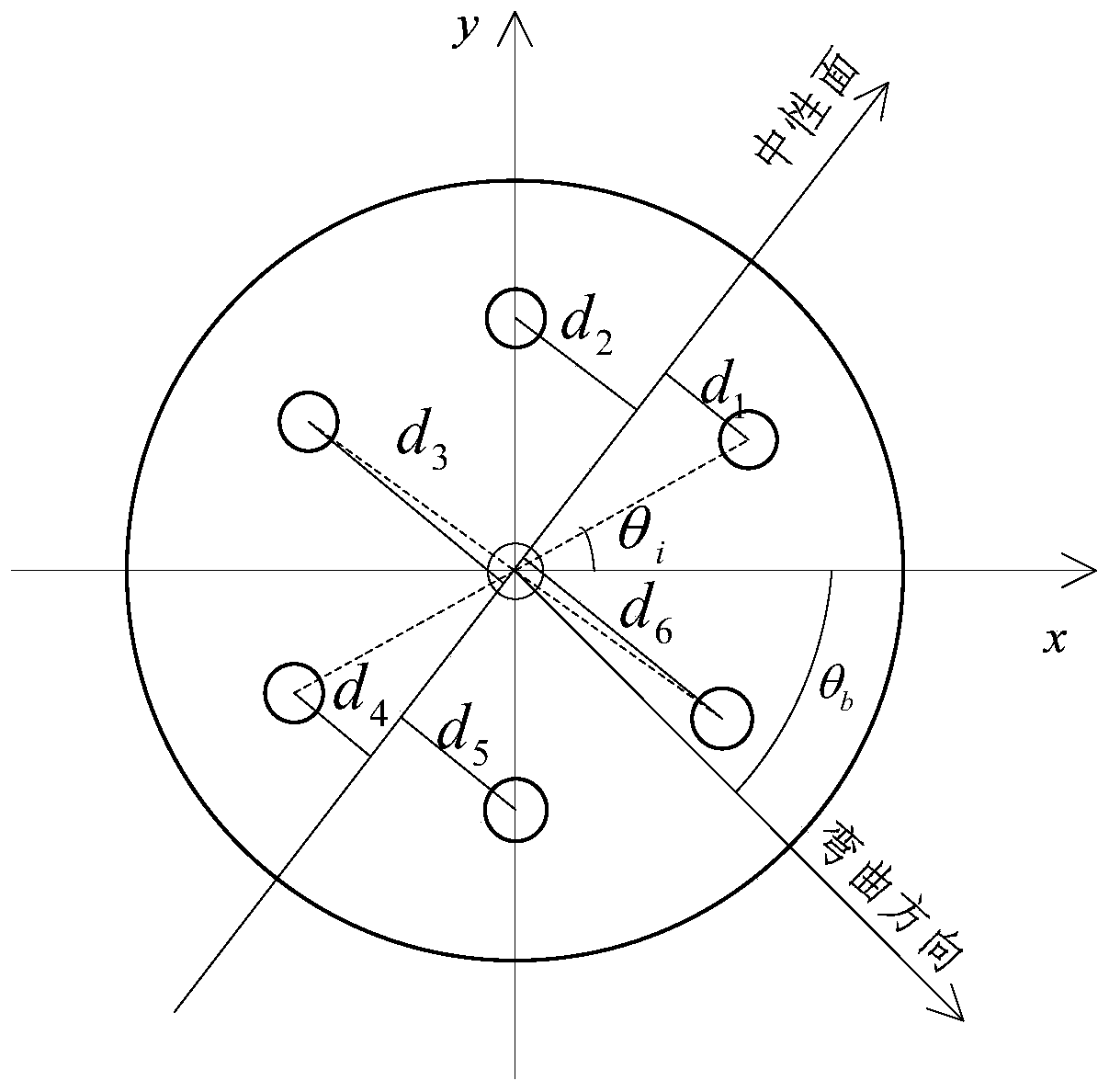

[0044] The invention discloses a three-dimensional shape perception monitoring method based on multi-core optical fiber, such as figure 1 A typical multi-core fiber is shown, when the fiber is bent and deformed, such as figure 2 As shown, taking the neutral plane of the fiber as the plane of symmetry, the strain of the fiber core is determined by the curvature of the fiber and the distance between the fiber core and the neutral plane. Such as Figure 3-4 As shown, according to the strain difference between different cores of the multi-core fiber, the curvature and bending direction of the fiber at the cross-section position can be calculated; further, as Figure 5 As shown, the three-dimensional shape sensing can be realized by spatial curve and surface reconstruction methods.

[0045] In this example, if Figure 6 , the three-dimensional shape perception monitoring method based on multi-core optical fiber, including:

[0046] In step 101, the measured strains of all fibe...

Embodiment 2

[0086] On the basis of the above embodiments, the present invention also discloses a multi-core optical fiber-based three-dimensional shape sensing monitoring system, including: an acquisition module, used to acquire the strain measured by all fiber gratings on each measurement section of the multi-core optical fiber; The inversion module is used to invert the curvature and bending direction of each measurement section according to the obtained strains measured by all fiber gratings on each measurement section; the interpolation encryption processing module is used to calculate the The curvature is interpolated and encrypted to obtain the curvature function of each measurement section; the vector expression building block is used to bring the curvature function of each measurement section into the Frenet equation group to obtain the vector expression of each measurement section; the iteration module is used to According to the vector expression of each measurement section, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com