Temporary plugging ball evaluation device and method for testing plugging performance of temporary plugging ball

An evaluation device and a technology for temporary blocking balls, which are applied in the field of experimental devices, can solve the problems of increasing the difficulty of fracturing process design and implementation, adverse effects of fracturing process, and large error in results, so as to ensure the evaluation of experimental results and evaluation results. Objective, to ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

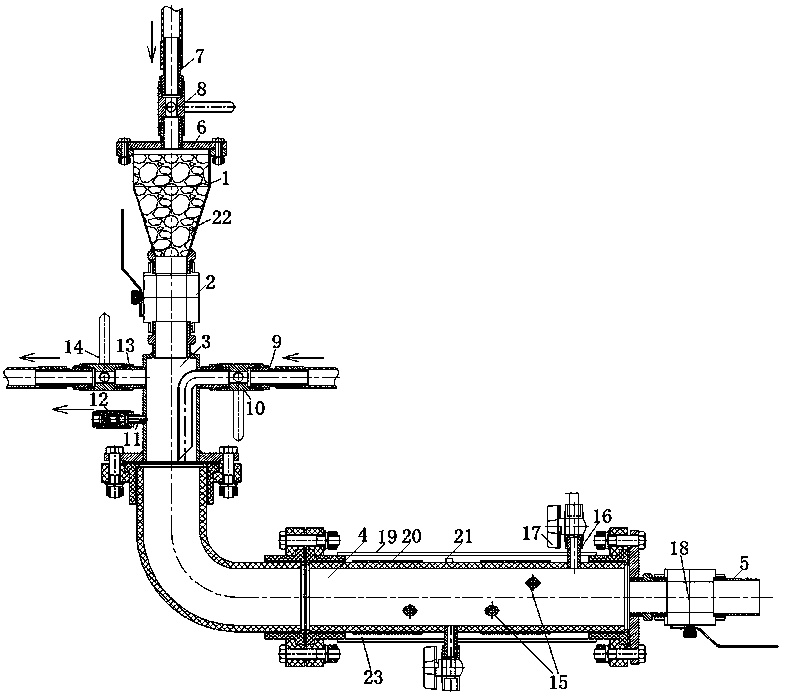

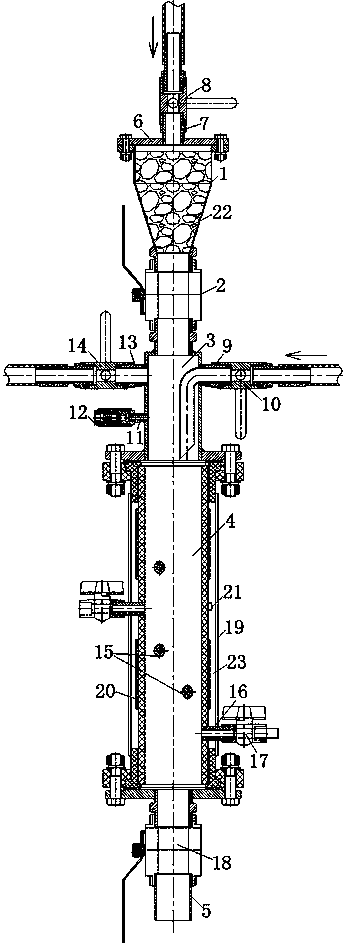

[0032] see figure 1 As shown, the present invention includes a storage bin 1, a shut-off valve 2, a guide chamber 3, a test cylinder 4 and a pressure relief pipe 5 sequentially connected from upstream to downstream, a storage bin 1, a cut-off valve 2, a guide chamber 3, and a test cylinder. 4 and the pressure relief pipe 5 there is a flow channel for the temporary blocking ball 22 (ie the blocking ball) to flow sequentially. The diameter of the flow channel is more than three times the diameter of the temporary blocking ball 22, that is, at least the diameter of the temporary blocking ball 22. three times. Among them, the storage bin 1, the shut-off valve 2 and the diversion chamber 3 are arranged on the same axis from upstream to downstream; the test cylinder 4 and the pressure relief pipe 5 are arranged on the same axis from upstream to downstream; the test cylinder The included angle between the center line of 4 and the center line of the diversion chamber 3 is about 90° (...

Embodiment 2

[0049] Other contents of this embodiment are the same as those of Embodiment 1, except that the test cylinder (including the elbow) is a non-transparent structure formed of stainless steel.

Embodiment 3

[0051] The other contents of this embodiment are the same as those of Embodiment 1 or 2, except that the angle between the center line of the test cylinder and the center line of the guide chamber is about 45° (or close to 45°). The invention is used to simulate the state of deviated wells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com