Experimental device for anti-seismic structure of stainless steel reinforced concrete column and its application method

A technology for reinforced concrete columns and earthquake-resistant structures, which is used in the testing of measuring devices, machine/structural components, and the use of stable torsion to test the strength of materials. Variable, Dangerous Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

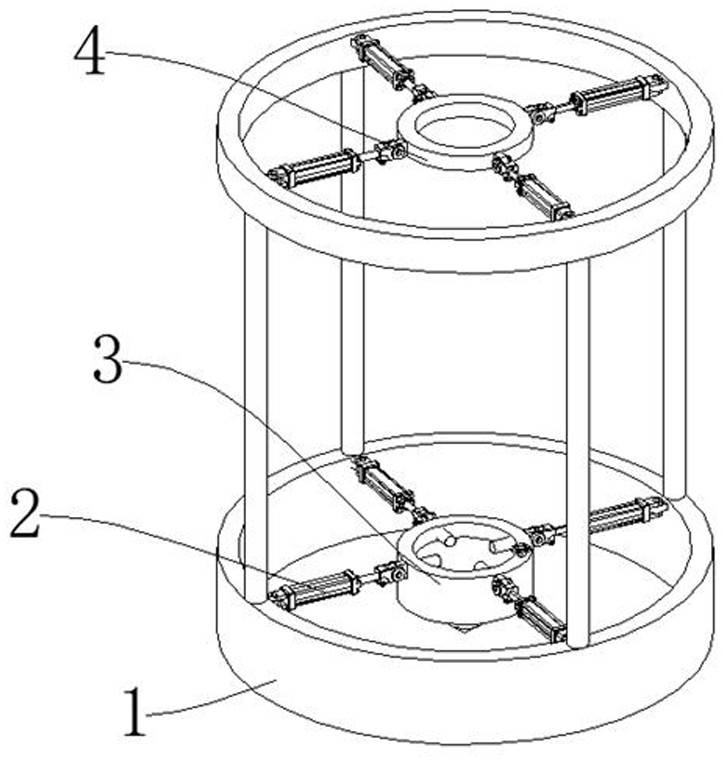

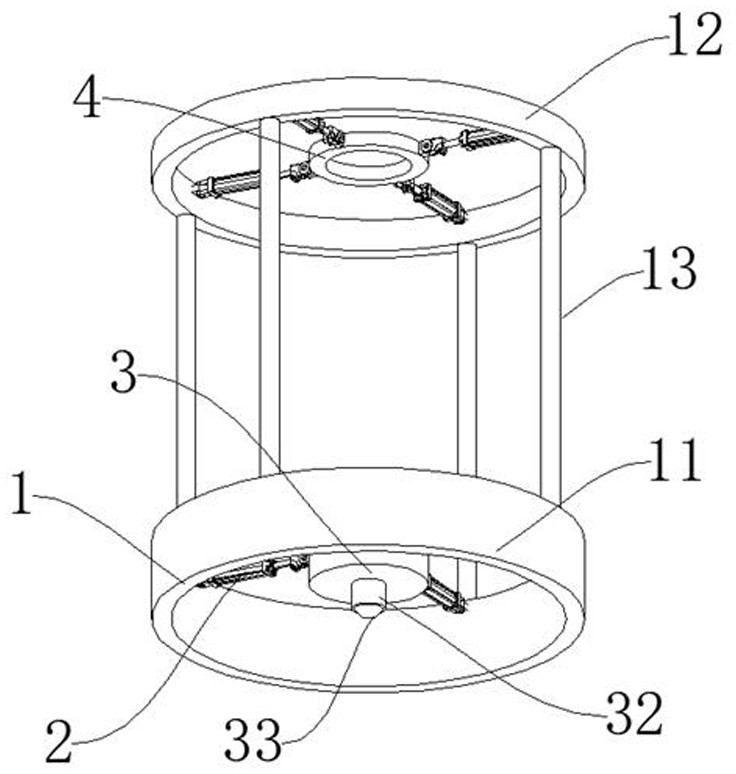

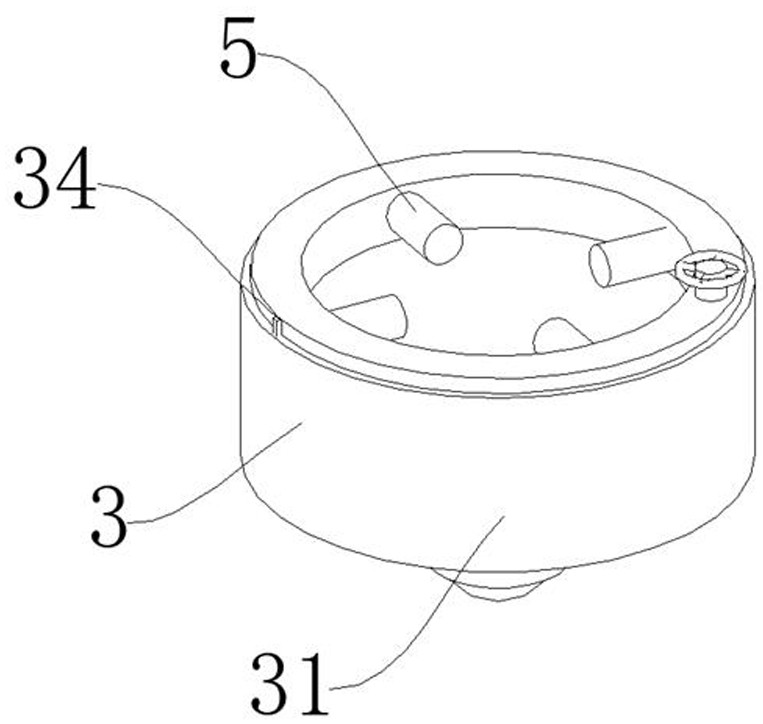

[0051] Such as Figure 1-Figure 10 As shown, the power mechanism 6 includes a passive sprocket 61, a chain 62, a driving sprocket 63, and a first motor 64. The passive sprocket 61 is connected to the second vibration matching block 36 of the supporting mechanism 3, and one side of the chain 62 is provided with a driving sprocket. 63, the passive sprocket 61 and the driving sprocket 63 are connected by a chain 62, the driving sprocket 63 is keyed to connect the first motor 64, the first motor 64 is connected to the supporting seat 31 of the supporting mechanism 3, and the first motor 64 drives the driving chain Wheel 63, chain 62, passive sprocket 61, make passive sprocket 61 drive the second vibration matching piece 36, the second vibration matching piece 36 cooperates with the first vibration matching piece 35, can make the first vibration matching piece 35 drive the lower end to fix The ring 51 vibrates; the fixing mechanism 1 includes a lower fixing base 11, an upper fixing...

Embodiment 2

[0053] Such as Figure 11 The difference between this embodiment and Embodiment 1 is that the power mechanism 6 includes a worm gear 611, a worm screw 612, and a second motor 613, the worm gear 611 is connected to the second vibration matching block 36 of the support mechanism 3, the input end of the worm gear 611 is connected to the worm screw 612, and the worm screw The input end of 612 is connected to the second motor 613, the fixed end of the second motor 613 is connected to the bearing seat 31 of the support mechanism 3, the second motor 613 is started, and the second motor 613 drives the worm 612 and the worm wheel 611, so that the worm wheel 611 drives the second vibration The matching block 36, the second vibration matching block 36 and the first vibration matching block 35 can make the first vibration matching block 35 drive the lower fixing ring 51 to vibrate.

[0054] The use method of the anti-seismic structure experimental device for the stainless steel reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com