Photonic crystal fiber with elliptical spiral elliptical hole structure

A technology of photonic crystal fiber and elliptical hole, which is applied in cladding fiber, optical waveguide light guide, light guide, etc., can solve the problems that the spectrum cannot be infinitely broadened, unfavorable supercontinuum spectrum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

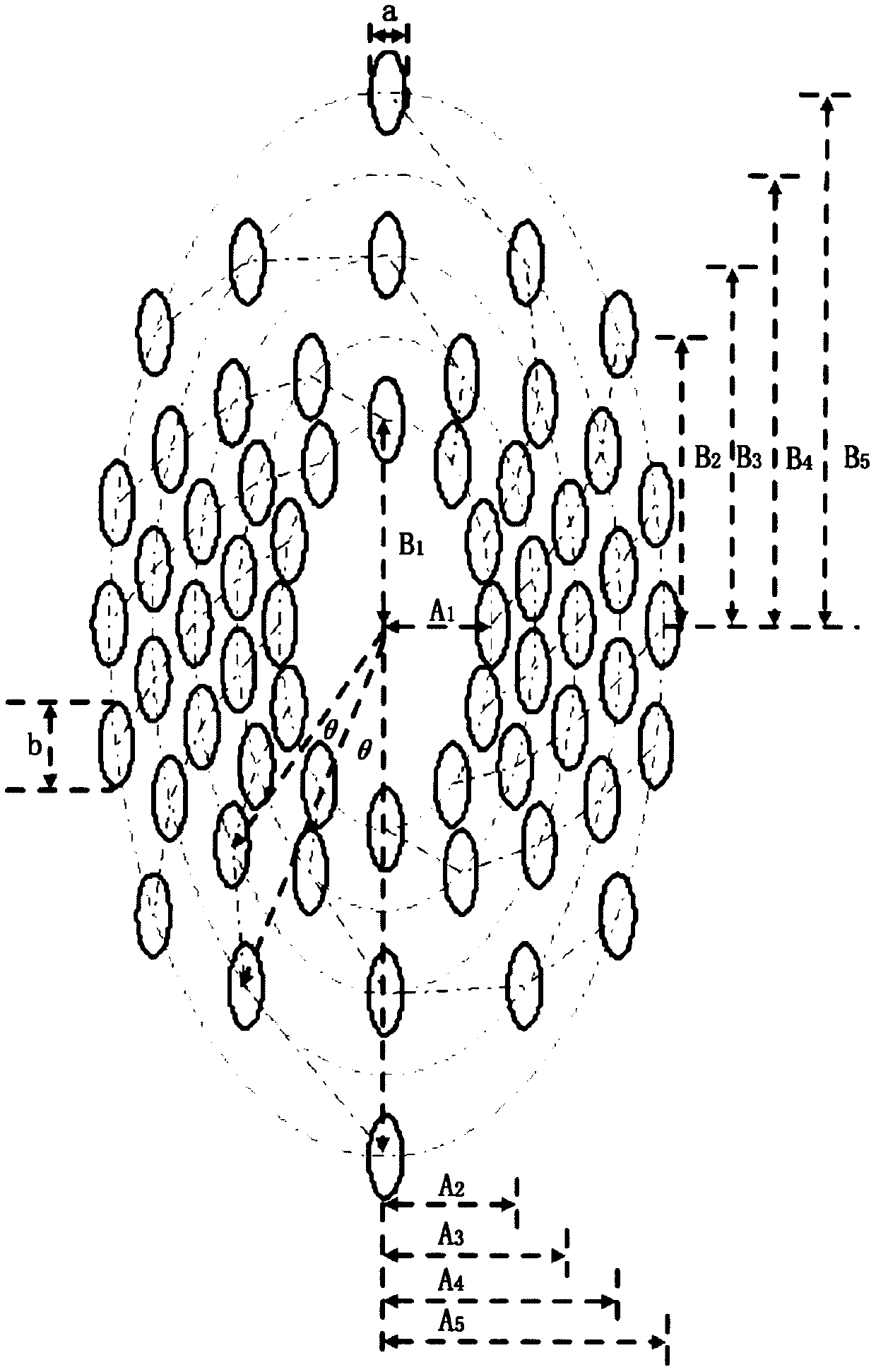

[0026] First, the ES-EH PCF calculation model was constructed using silicate soft glass (SF57) as the substrate. Such as figure 1 As shown, ES-EH PCF has 12 helical arms, and each helical arm contains 5 elliptical air holes. Different spiral arms have different bending radians, and the spacing of the elliptical air holes in them is also different. To provide a quantitative design, the structure can be described from another perspective: the ES-EH PCF is constructed of 5 layers of elliptical envelopes (red dotted lines), each layer has 12 elliptical air holes. Note that the ellipticity ratios of the five-layer elliptic envelopes are equal, namely Where B is the major axis of the ellipse envelope, A is the minor axis of the ellipse envelope, and A 1 , A 2 , A 3 , A 4 , A 5 are the minor axis of the ellipse envelope of each layer, B 1 , B 2 , B 3 , B 4 , B 5 are the major axes of the elliptical envelopes of each layer, and the distance between each layer is equal, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com