Method for binding silicon rubber belt on parallel flow ring of increased-safety explosion-proof motor

A technology of explosion-proof motors and rubber belts, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of hidden dangers in production safety, difficult to reach the location of secondary treatment, etc., and achieve the elimination of corona and discharge, good electrical performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

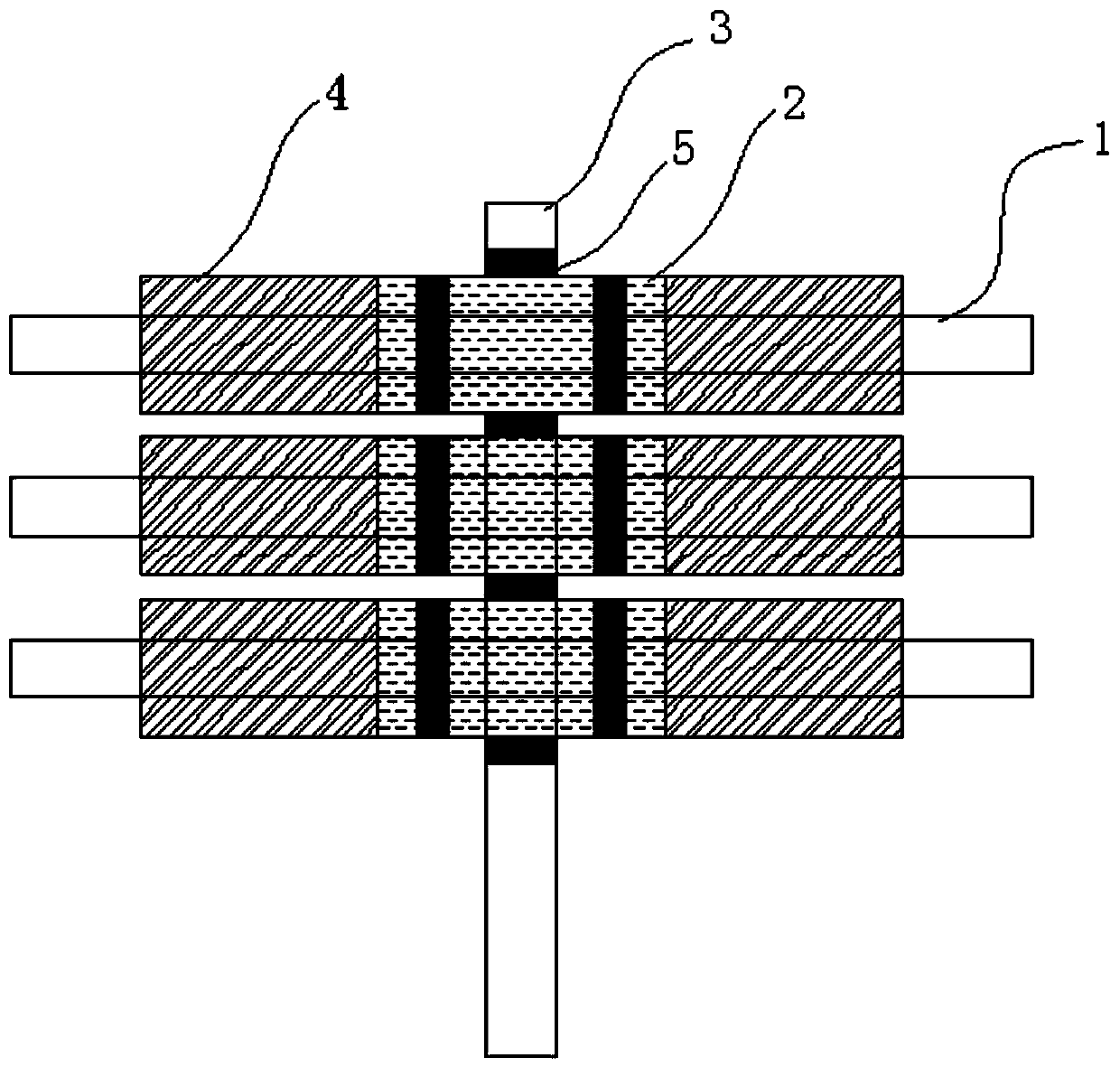

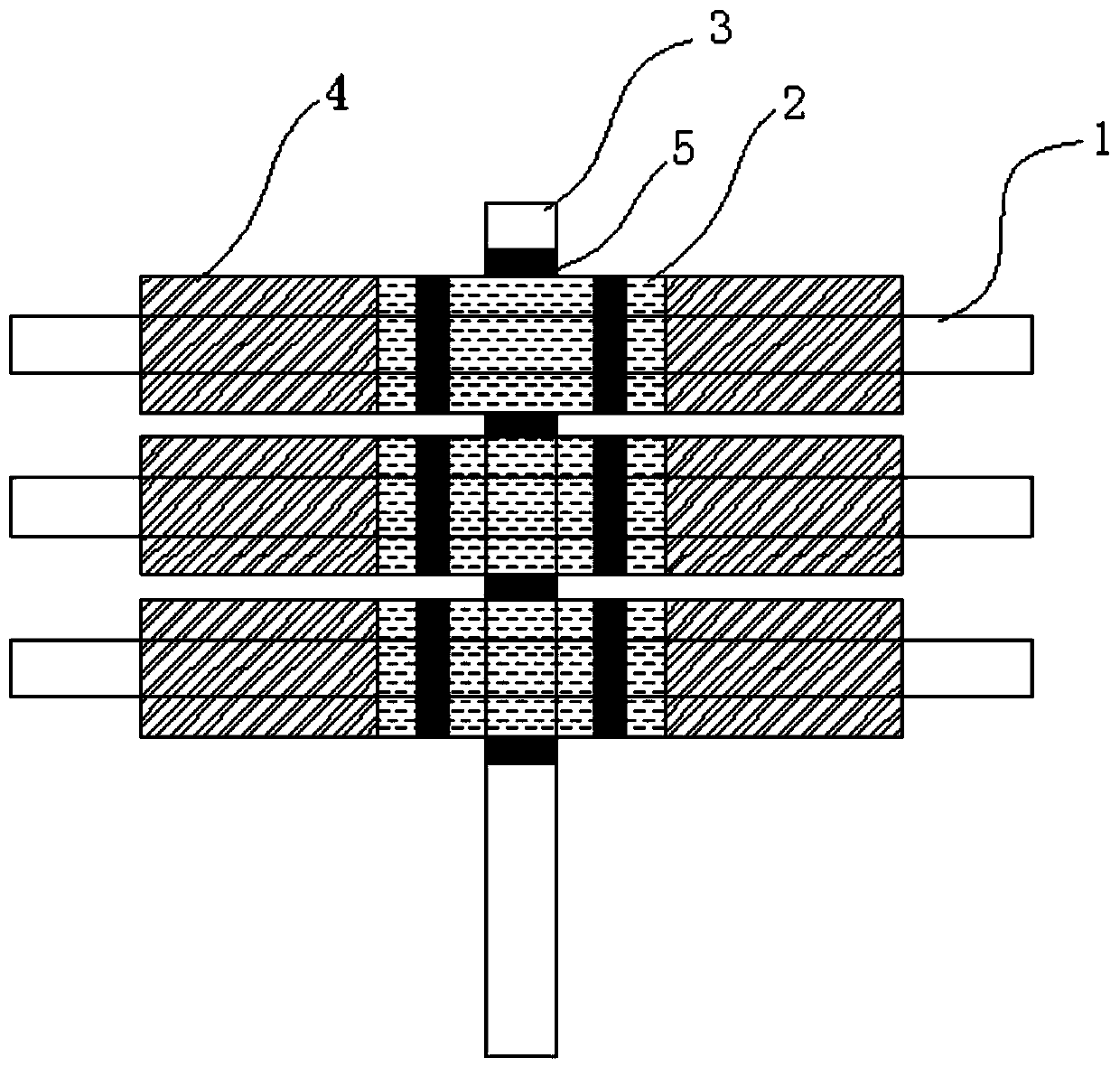

[0020] see figure 1 . A binding method of applying a silicone rubber belt to the parallel flow ring of an increased safety explosion-proof motor according to the present invention includes a parallel flow ring 1 and a silicon rubber belt 2 wrapped outside the parallel flow ring to connect the parallel flow ring 1 and the parallel flow ring. The explosion-proof connection of bracket 3 specifically includes the following steps:

[0021] Step 1: Use mica tape 4 to bind the surface of the parallel flow ring 1 to form a mica tape binding area. In order to ensure the insulation performance of the edge and to reserve enough space for the silicone rubber band binding area, the width of the mica band banding area shall be at least 270mm.

[0022] Step 2: Mark the width of the bracket in the middle of the mica band binding area t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com