Electric pump system and method

A technology for mechanical pumps and pump inlets, applied in the field of fluid temperature assessment, which can solve the problems of oil pumps not monitoring oil conditions, large physical space, and inability to accurately determine the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

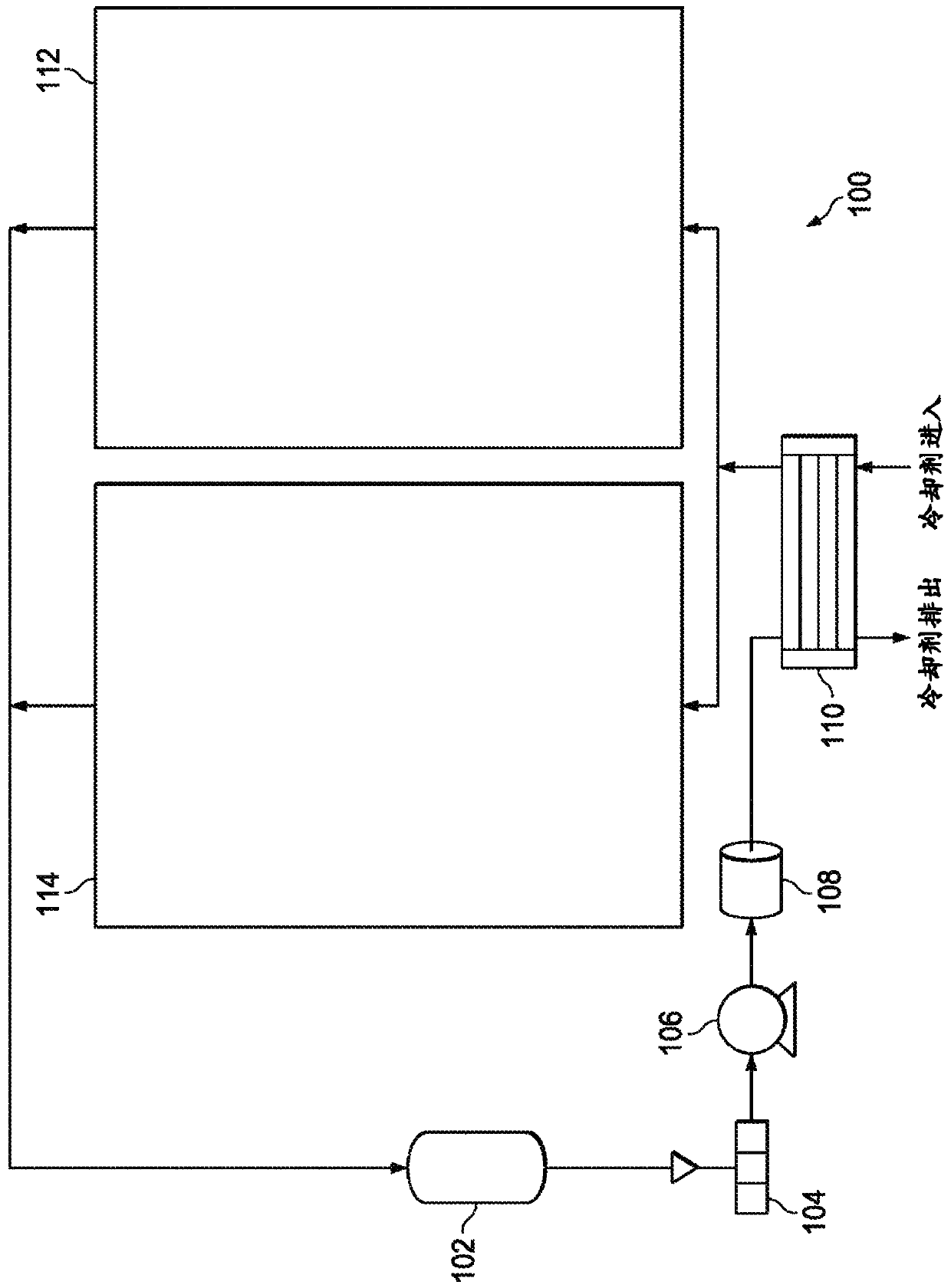

[0030] figure 1 A schematic diagram of a cooling and lubrication system 100 for circulating a fluid (eg, oil) through various components of an electric drive unit of an electric vehicle is shown in accordance with disclosed embodiments. Subsequent descriptions of other figures refer to figure 1 s component. exist figure 1 In , general reference numerals may be used to refer to components identified in those figures. Additionally, although the embodiments described herein are in the context of oil-based systems, other fluids may be used. For example, any fluid that provides suitable lubrication, heat transfer, and flow characteristics for a particular application or pump size can be used.

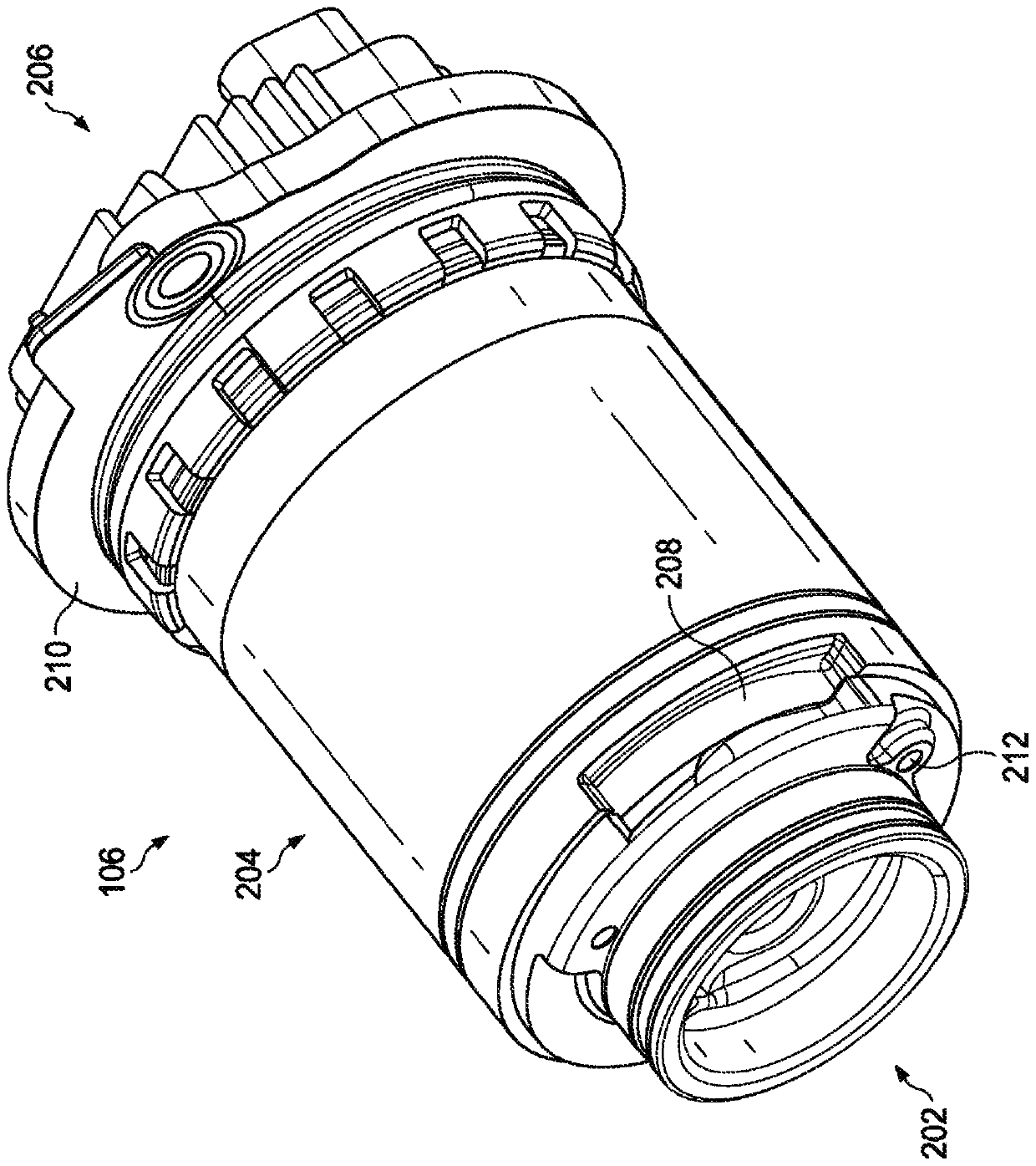

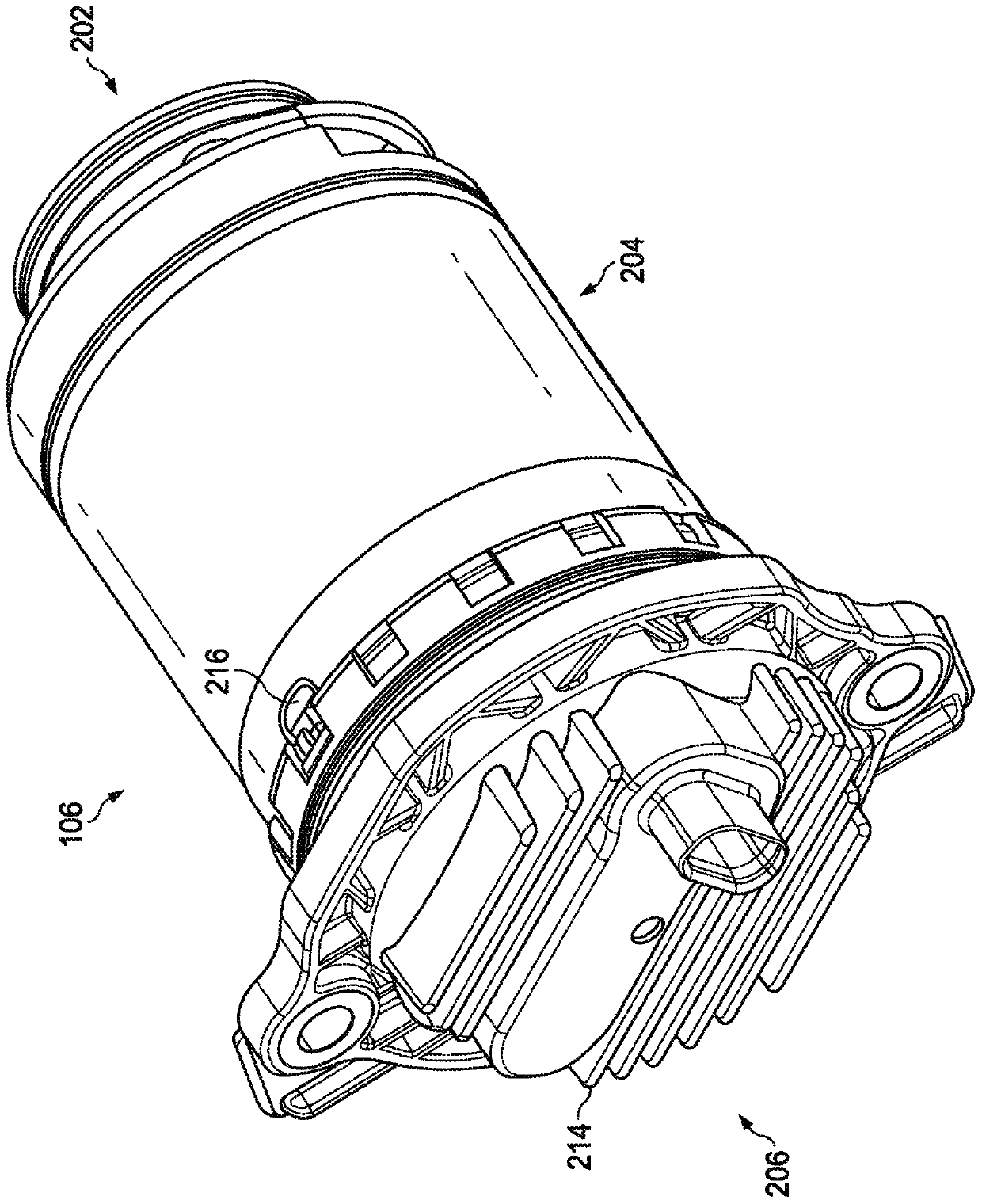

[0031] From an oil reservoir 102 (an oil reservoir external to the drive unit), which may include an oil sump or dry sump system, the oil flows through a mesh filter 104 to an electric pump system 106 . Oil pumped from the electric pump system 106 passes through an oil filter 108 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com