A kind of plane mask processing method

A processing method and mask technology, applied in protective clothing, clothing, applications, etc., can solve the problems of difficult to achieve high-speed production of flat masks, low efficiency, slow speed, etc., to reduce the transfer and secondary conveying process, improve production efficiency, Realize the effect of high-speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

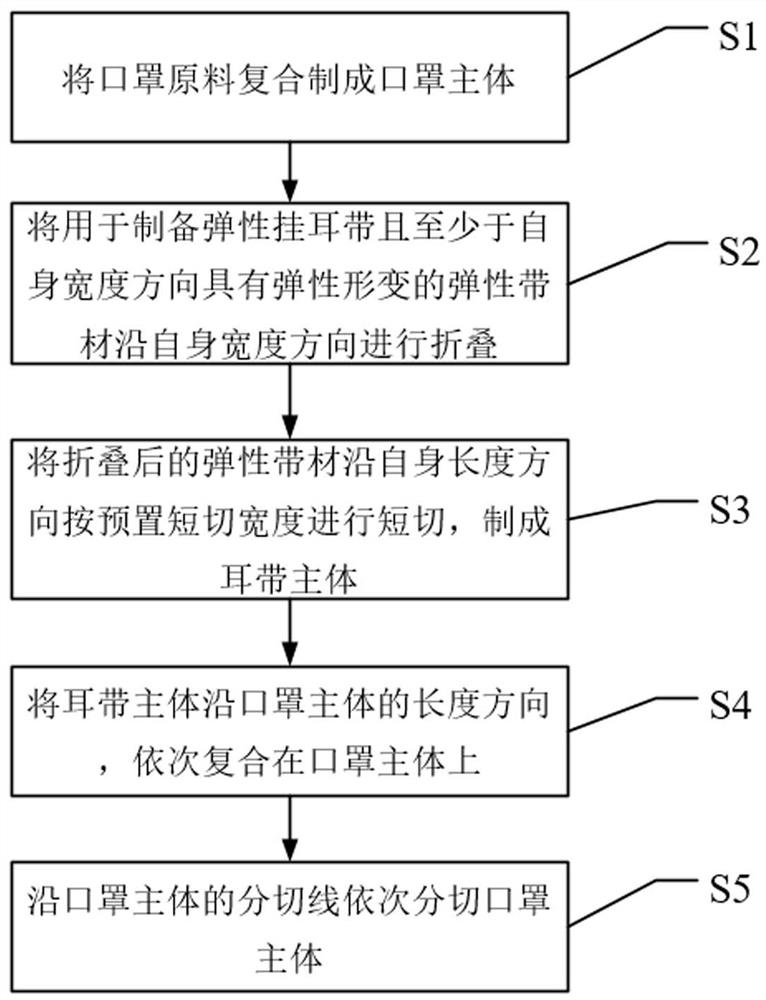

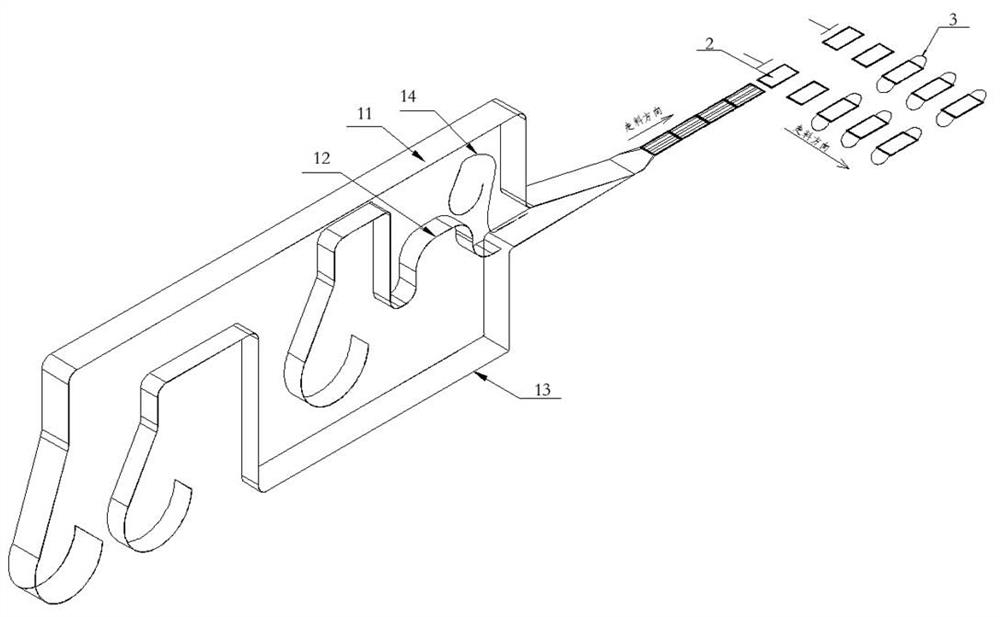

[0034] This application provides a method for processing flat masks, see figure 1 , Figure 4 , Figure 5 as well as Image 6 shown, including steps:

[0035] S1. Composite the mask raw materials to make the main body of the mask; what needs to be said is, if Figure 4 As shown, the mask main body 2 production steps can be the same as the traditional mask main body 2 production steps, that is, the existing mask main body production equipment can be used for outer layer non-woven fabric 11, middle layer melt blown cloth 12, inner layer non-woven fabric 13 And mask raw materials such as bridge of the nose strip 14 are compounded to generate the required mask main body 2, those skilled in the art can make appropriate transformations on this basis, and specifically do not limit.

[0036] S2. Fold the elastic strip material used to prepare the elastic ear strap and have elastic deformation at least less than its own width direction along its own width direction; it should be no...

Embodiment 2

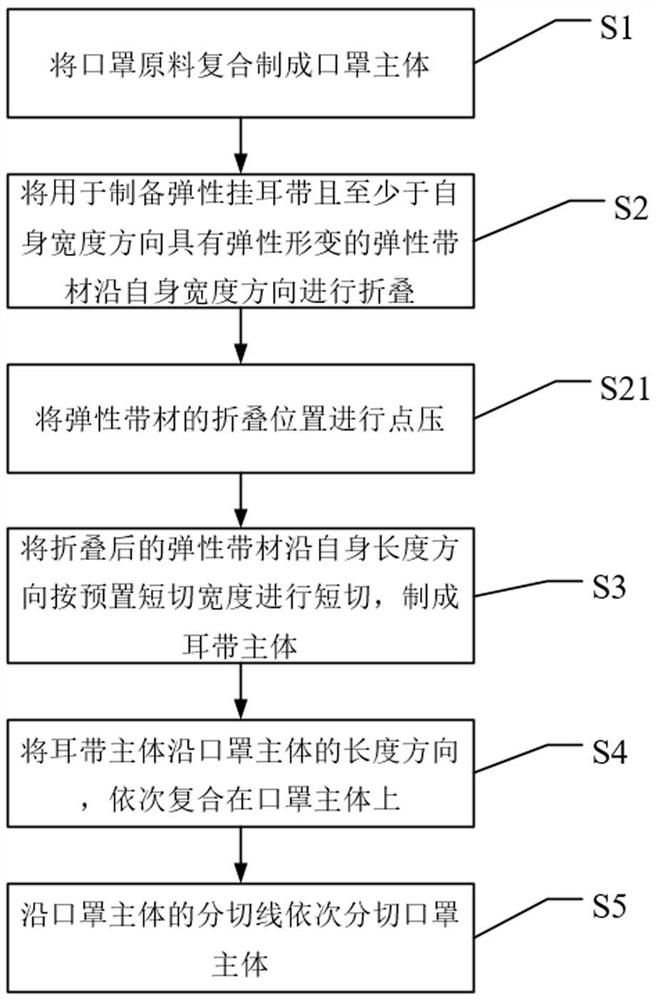

[0043] In addition to the method steps provided in the first embodiment above, the present application also includes the following method steps:

[0044] S21. Point pressing the folded position of the elastic strip. It should be noted that: due to the recovery deformation of the folded elastic strip, this easily affects the accuracy of the chopping process of the elastic strip 4 and also easily affects the subsequent transfer and compounding. For this reason, the present application adds a point pressing step between step S2 and step S3 to carry out point pressure on the folded position of the elastic strip 4 to ensure that the elastic strip 4 will not recover from deformation, and it is also convenient for subsequent use. Easy to pull and unfold. like Figure 7 as well as Figure 8 As shown, the folding position of the elastic strip can be point-pressed by point-pressing equipment such as the point-pressing roller 6, so that the overlapping positions of the elastic strip a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com