Flue gas purification device

A flue gas purification and washing tower technology, applied in gas treatment, chemical instruments and methods, using liquid separation agents, etc., can solve the problems of large flue gas treatment capacity, affecting production efficiency, increasing system pressure drop, etc., to achieve threshing Reduced energy consumption, improved threshing effect, and reduced system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

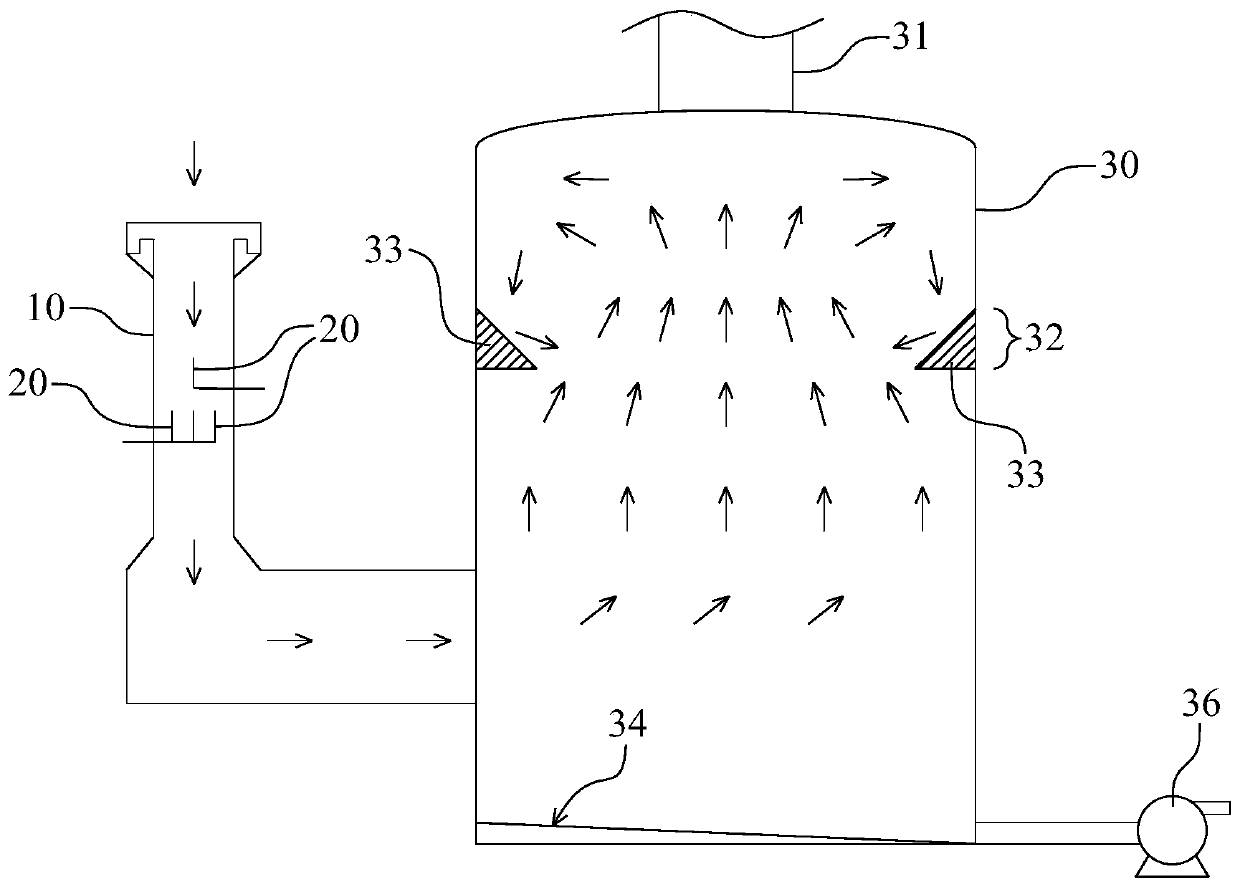

[0010] A flue gas purification device, comprising a washing pipe 10 with the mouth facing upwards, the washing pipe 10 is provided with a nozzle 20, the outlet of the nozzle 20 points to the mouth of the washing pipe 10, and the end of the washing pipe 10 communicates with the washing tower 30 , The top of the washing tower 30 is provided with a flue gas outlet 31 , and the flue gas circulation path in the washing tower 30 is provided with a reduced diameter portion 32 . The flue gas enters the washing tower 30 after fully mixing and reacting with the liquid ejected from the nozzle 20 in the washing pipe 10, and accelerates to generate turbulent flow at the narrowing part 32, and the dust particles entering the washing tower 30 with the air flow collide at the turbulent flow When it falls, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap