A kind of preparation method and application of ni-cnt catalyst for hydrogenated dimer acid production

A technology for hydrogenating dimer acid and catalyst, which is applied in the field of nanomaterial technology and organic chemical industry, which can solve the problems of limited conversion rate of dimer acid raw materials, catalyst service time failure, and low catalyst activity, so as to improve reaction rate and raw material conversion efficiency, long service life, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method and application of a catalyst for hydrogenated dimer acid production, comprising the steps of:

[0031] Step 1: preparing a Ni-CNT catalyst for hydrogenated dimer acid production;

[0032] Step 2: Online activation of Ni-CNT catalyst;

[0033] Switch the device for preparing crude Ni-CNT catalyst to nitrogen replacement and hydrogen atmosphere activation conditions to reduce the Ni in Ni-CNT to a simple reduction state, which is used for hydrogenation of dimer acid to produce hydrogenated dimer acid;

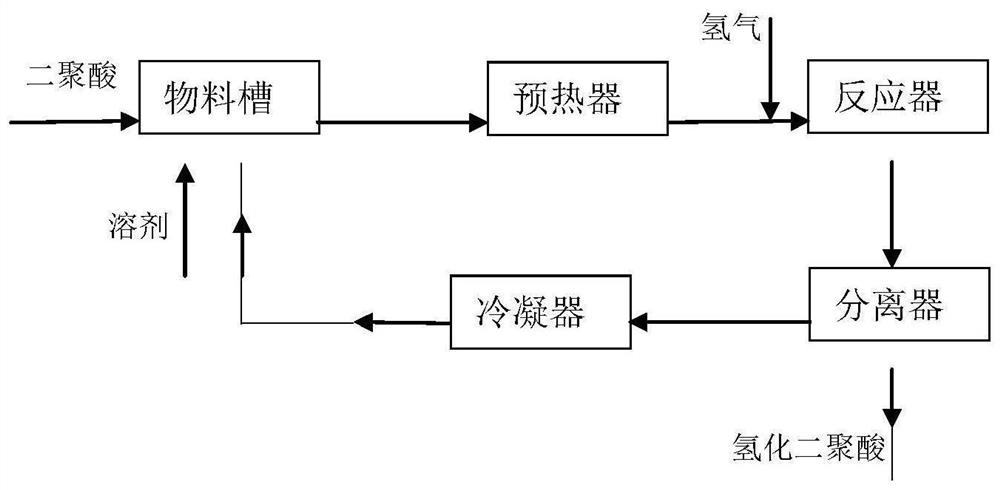

[0034] Step 3: dimer acid hydrogenation reaction generates hydrogenated dimer acid;

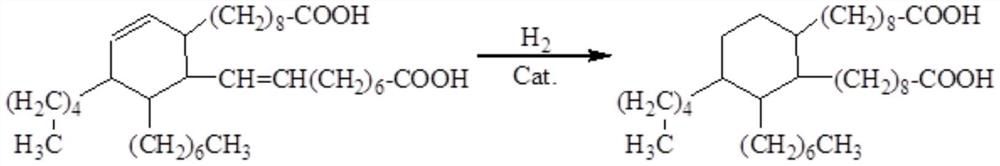

[0035] The dimer acid is diluted with a dissolving inert solvent, and after preheating, it is metered into the activated and heated catalyst after preheating; the dimer acid (ie unsaturated dimer acid) has 1-3 C=C bonds.

[0036] Step 4: Vacuum the separator, separate the inert solvent online, and circulate the inert solvent to dilute the dimer acid; collect the hy...

Embodiment 1

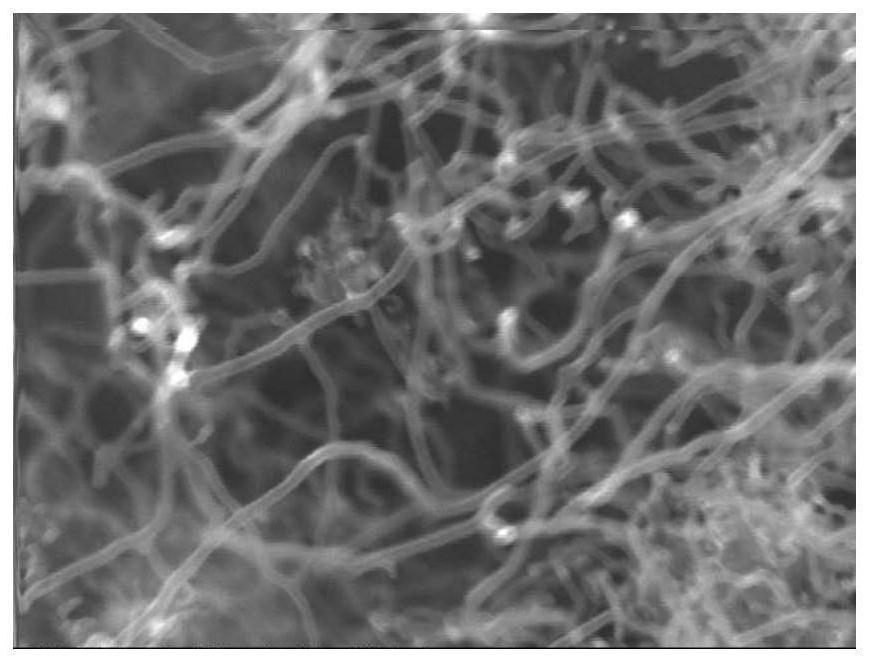

[0043] Catalyst preparation: Mix nickelocene, ethanol, and carbon disulfide at a molar ratio of 1:50:5, spray into the quartz tube, the quartz tube is an argon atmosphere, the temperature inside the quartz tube is 300°C, the flow rate of argon gas is 0.800L / min, and the reaction time is 50min , cooled to room temperature under the conditions of a water vapor flow rate of 0.040L / min and an argon flow rate of 0.800L / min to obtain a fibrous crude product nickel-carbon nanotube (Ni-CNT) catalyst, the crude product Ni-CNT catalyst was washed and dried For later use; place the crude Ni-CNT catalyst in a quartz tube, replace the air in the quartz tube with an inert gas, and then pass in a hydrogen flow, the hydrogen flow rate is 1.000L / min, the activation temperature is 250°C, and the activation time is 200min, so that the Ni-CNT Ni in the catalyst is reduced to a single substance to obtain an activated Ni-CNT catalyst, which is used as a catalyst for hydrogenating dimer acid to produ...

Embodiment 2

[0046] Catalyst preparation: Mix nickelocene, ethanol, and carbon disulfide at a molar ratio of 1:100:5, spray into the quartz tube, the quartz tube is an argon atmosphere, the temperature inside the quartz tube is 350°C, the argon flow rate is 1.000L / min, and the reaction time is 30min , cooled to room temperature under the conditions of a water vapor flow rate of 0.040L / min and an argon flow rate of 1.000L / min to obtain a fibrous crude product nickel-carbon nanotube (Ni-CNT) catalyst, the crude product Ni-CNT catalyst was washed and dried Reserve for later use; place the crude Ni-CNT catalyst in a quartz tube, replace the air in the quartz tube with an inert gas, and then pass in a hydrogen flow, the hydrogen flow rate is 1.000L / min, the activation temperature is 280°C, and the activation time is 200min, so that the Ni-CNT Ni in the catalyst is reduced to a single substance to obtain an activated Ni-CNT catalyst, which is used as a catalyst for hydrogenating dimer acid to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com