Disc type automobile casting surface treatment device

A surface treatment device and casting technology, which is applied in the field of mechanical parts processing, can solve the problems of poor operation flexibility, troublesome operation, difficult grinding operation, etc., achieve synchronous grinding effect, improve the quality of grinding treatment, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

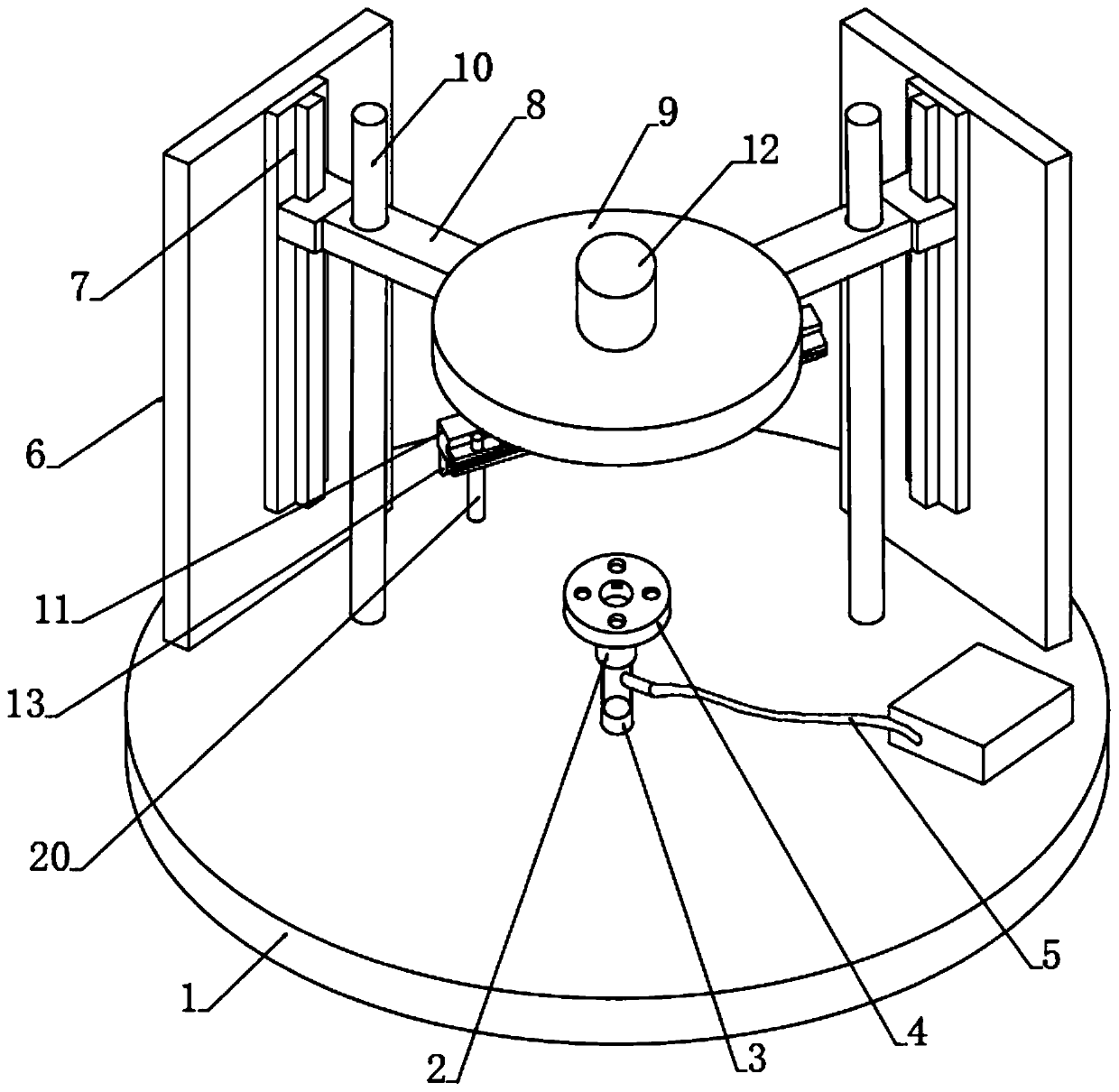

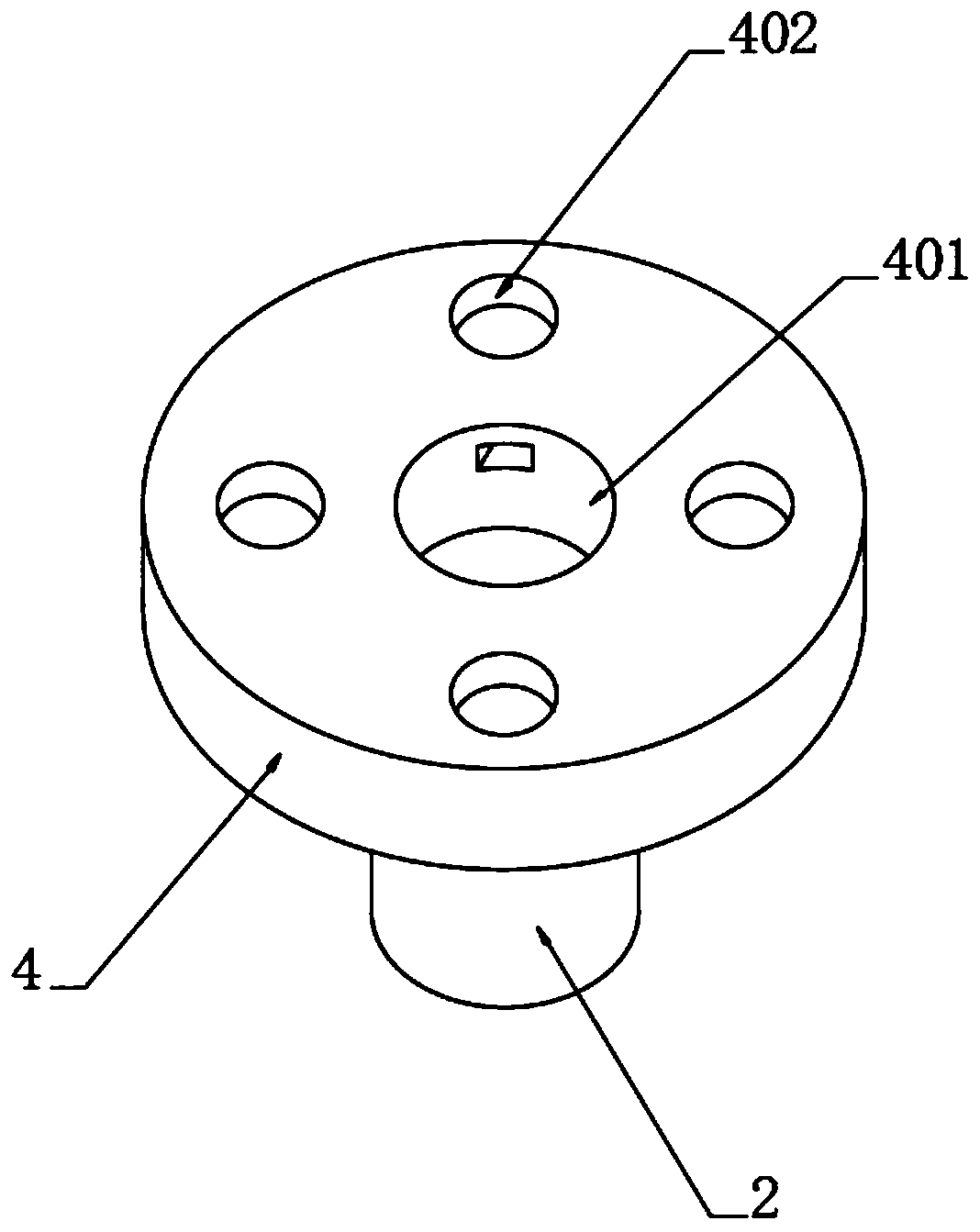

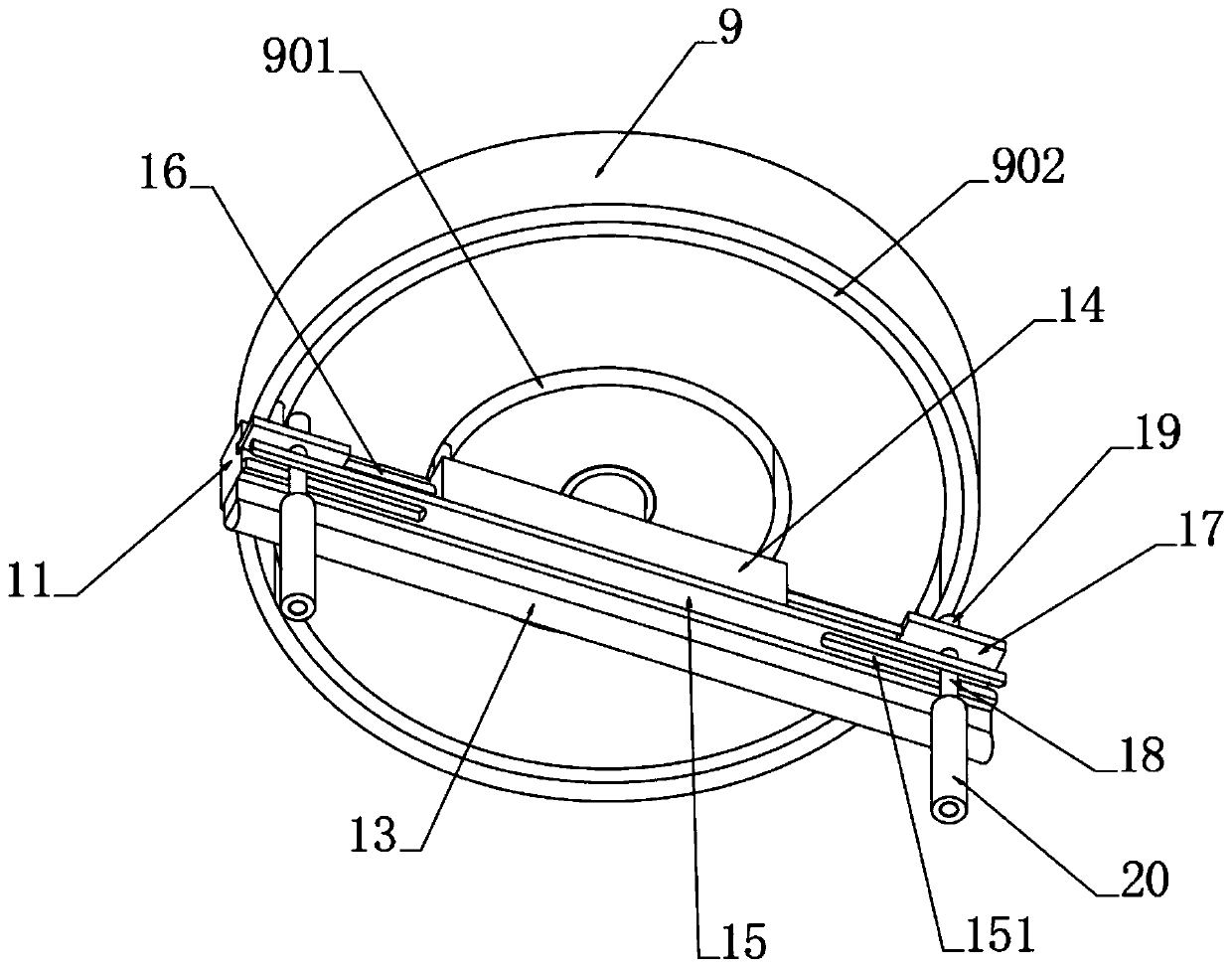

[0036] see Figure 1-2 , a surface treatment device for disc-like automotive castings, comprising an operating console 1, an air extraction pipe 3 is fixedly installed in the middle of the upper end of the operating table 1, and a casting adsorption mechanism is installed on the top of the air extraction pipe 3, and the air extraction pipe 3 is connected through an air guide pipe 5. The suction device is externally connected, and the casting adsorption mechanism includes a connecting pipe 2 that is threadedly connected to the top of the suction pipe 3. The top of the connecting pipe 2 is communicated with an adsorption disk 4, and the top of the adsorption disk 4 is provided with a main adsorption chamber 401 that communicates with the connecting pipe 2. , the upper end of the adsorption disc 4 is provided with a plurality of auxiliary adsorption chambers 402 connected with the main adsorption chamber 401 around the upper end, and the main adsorption chambers 401 and auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com