Prestressed concrete high-strength anti-corrosion pipe pile and production method thereof

A production method and prestressing technology, applied in sheet pile walls, reinforcement forming, infrastructure engineering, etc., can solve the problems of easy compression deformation of end plates, weak connection, small contact area, etc., to enhance the overall strength and resistance to Compression capacity, excellent anti-corrosion performance and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

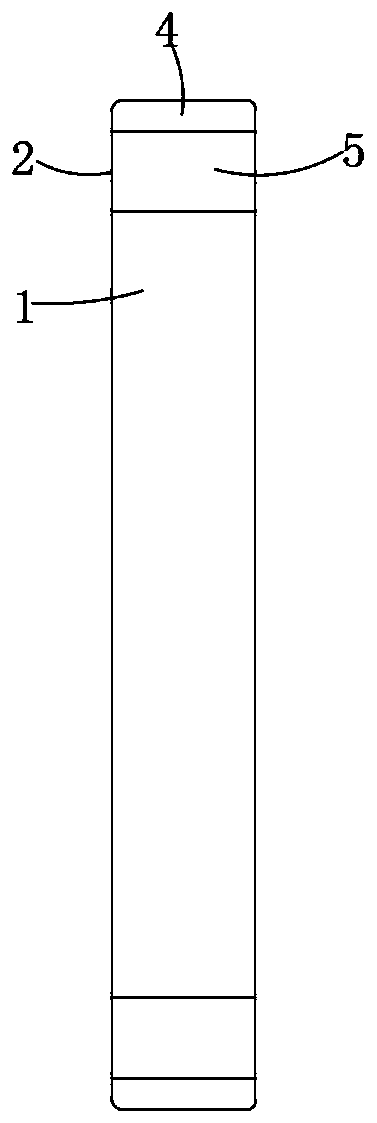

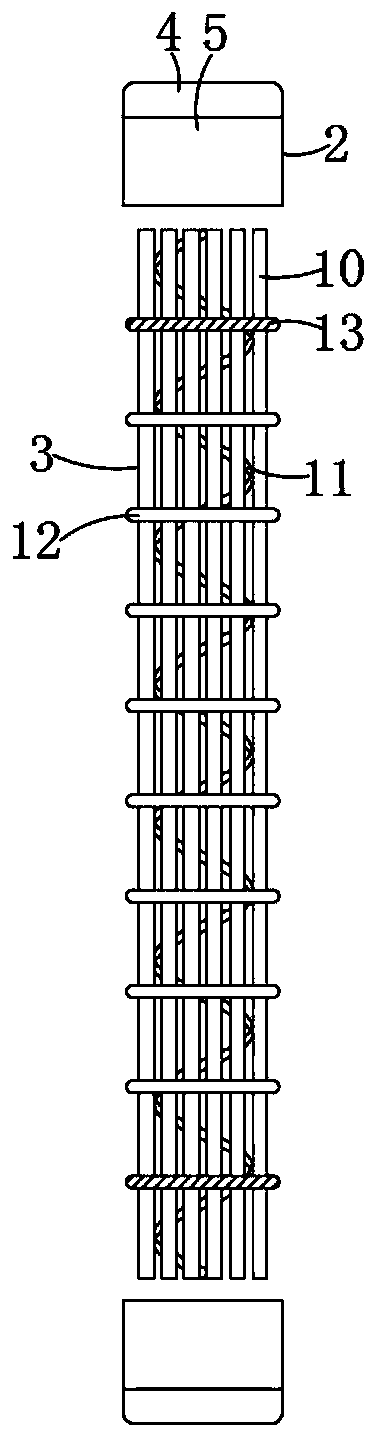

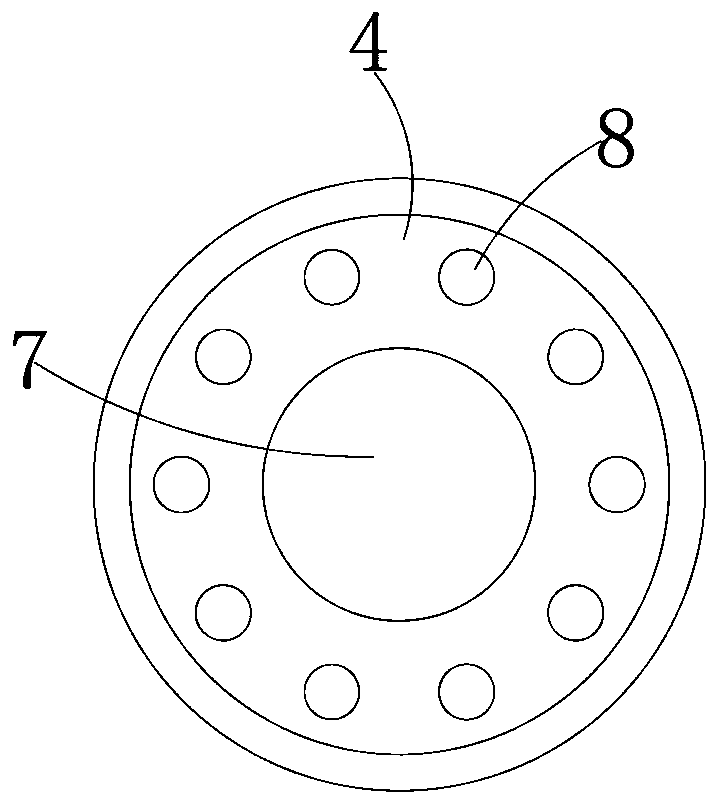

[0033] A prestressed concrete high-strength anti-corrosion pipe pile, including a pile body 1 and an end plate 2, the two end plates 2 are symmetrically arranged on both ends of the pile body 1, a steel skeleton 3 is arranged inside the pile body 1, and the end plate 2 includes a connection plate 4 and a reinforcement sleeve 5, the reinforcement sleeve 5 is arranged on one end of the pile body 1, the connection plate 4 is arranged on the end of the reinforcement sleeve 5 away from the pile body 1, and the connection plate 4 is close to the end of the reinforcement sleeve 5 An annular groove 6 is provided on the outer side wall of the pile, and the end of the reinforcement sleeve 5 away from the pile body 1 is welded in the groove 6 .

[0034] The end plate 2 is a split assembly design, the production and processing technology is simpler and more convenient, and the reinforcement sleeve 5 welded in the groove 6 can prevent the connection plate 4 from The pile is deformed and da...

Embodiment 2

[0047] A prestressed concrete high-strength anti-corrosion pipe pile, including a pile body 1 and an end plate 2, the two end plates 2 are symmetrically arranged on both ends of the pile body 1, a steel skeleton 3 is arranged inside the pile body 1, and the end plate 2 includes a connection plate 4 and a reinforcement sleeve 5, the reinforcement sleeve 5 is arranged on one end of the pile body 1, the connection plate 4 is arranged on the end of the reinforcement sleeve 5 away from the pile body 1, and the connection plate 4 is close to the end of the reinforcement sleeve 5 An annular groove 6 is provided on the outer side wall of the pile, and the end of the reinforcement sleeve 5 away from the pile body 1 is welded in the groove 6 .

[0048] The end plate 2 is a split assembly design, the production and processing technology is simpler and more convenient, and the reinforcement sleeve 5 welded in the groove 6 can prevent the connection plate 4 from The pile is deformed and da...

Embodiment 3

[0061] A prestressed concrete high-strength anti-corrosion pipe pile, including a pile body 1 and an end plate 2, the two end plates 2 are symmetrically arranged on both ends of the pile body 1, a steel skeleton 3 is arranged inside the pile body 1, and the end plate 2 includes a connection plate 4 and a reinforcement sleeve 5, the reinforcement sleeve 5 is arranged on one end of the pile body 1, the connection plate 4 is arranged on the end of the reinforcement sleeve 5 away from the pile body 1, and the connection plate 4 is close to the end of the reinforcement sleeve 5 An annular groove 6 is provided on the outer side wall of the pile, and the end of the reinforcement sleeve 5 away from the pile body 1 is welded in the groove 6 .

[0062] The end plate 2 is a split assembly design, the production and processing technology is simpler and more convenient, and the reinforcement sleeve 5 welded in the groove 6 can prevent the connection plate 4 from The pile is deformed and da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com