Round honeycomb ceramic automatic detecting device

A honeycomb ceramic and automatic detection technology, applied in the field of ceramic processing, can solve the problems that the distance between the honeycomb ceramic and the honeycomb ceramic cannot be guaranteed, affect the detection of the honeycomb ceramic, and cannot guarantee the honeycomb ceramic, so as to achieve good protection, avoid direct connection, avoid friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

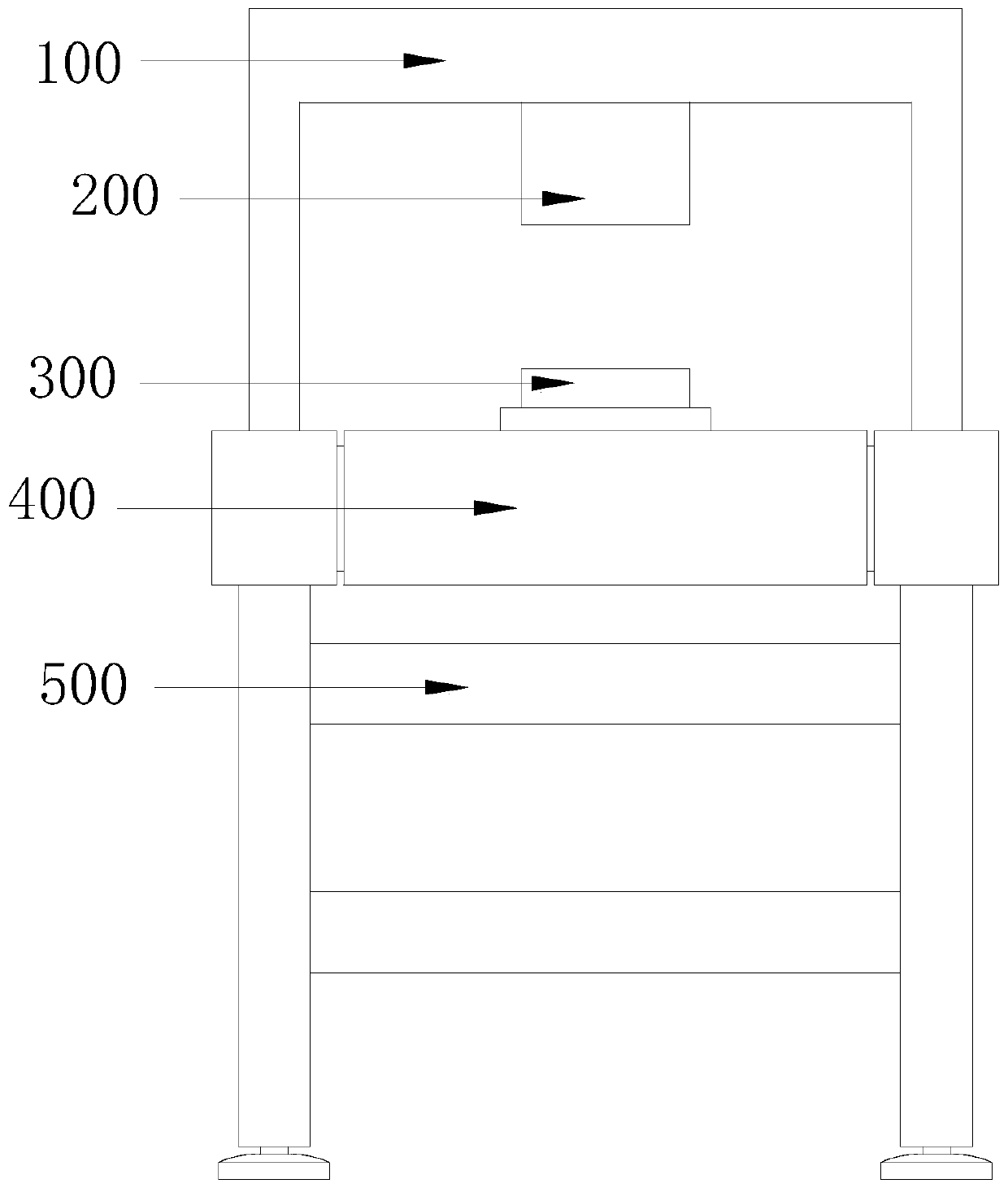

[0034] see Figure 1-7 , the present invention provides a technical solution of circular honeycomb ceramic automatic detection equipment: its structure includes a support frame 100, a detection device 200, a honeycomb ceramic 300, a conveyor belt 400, and a conveyor body 500, and the conveyor body 500 is equipped with There is a conveyor belt 400, and a honeycomb ceramic 300 is placed on the conveyor belt 400. A detection device 200 is arranged above the honeycomb ceramic 300. The detection device 200 is installed on a support frame 100, and the support frame 100 is connected to the conveyor body 500. make a mechanical connection;

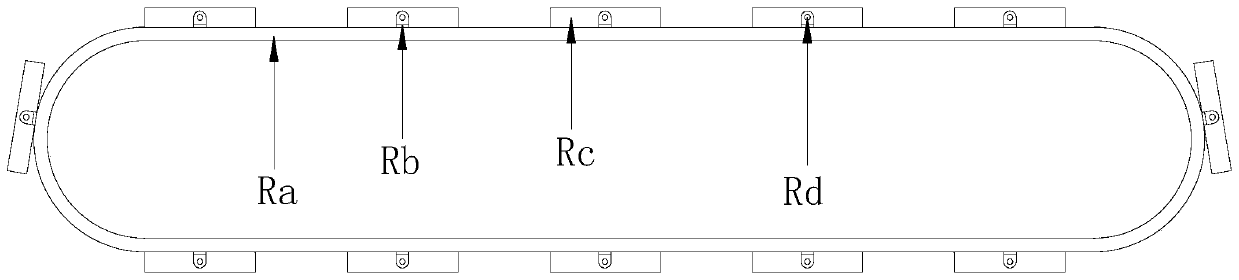

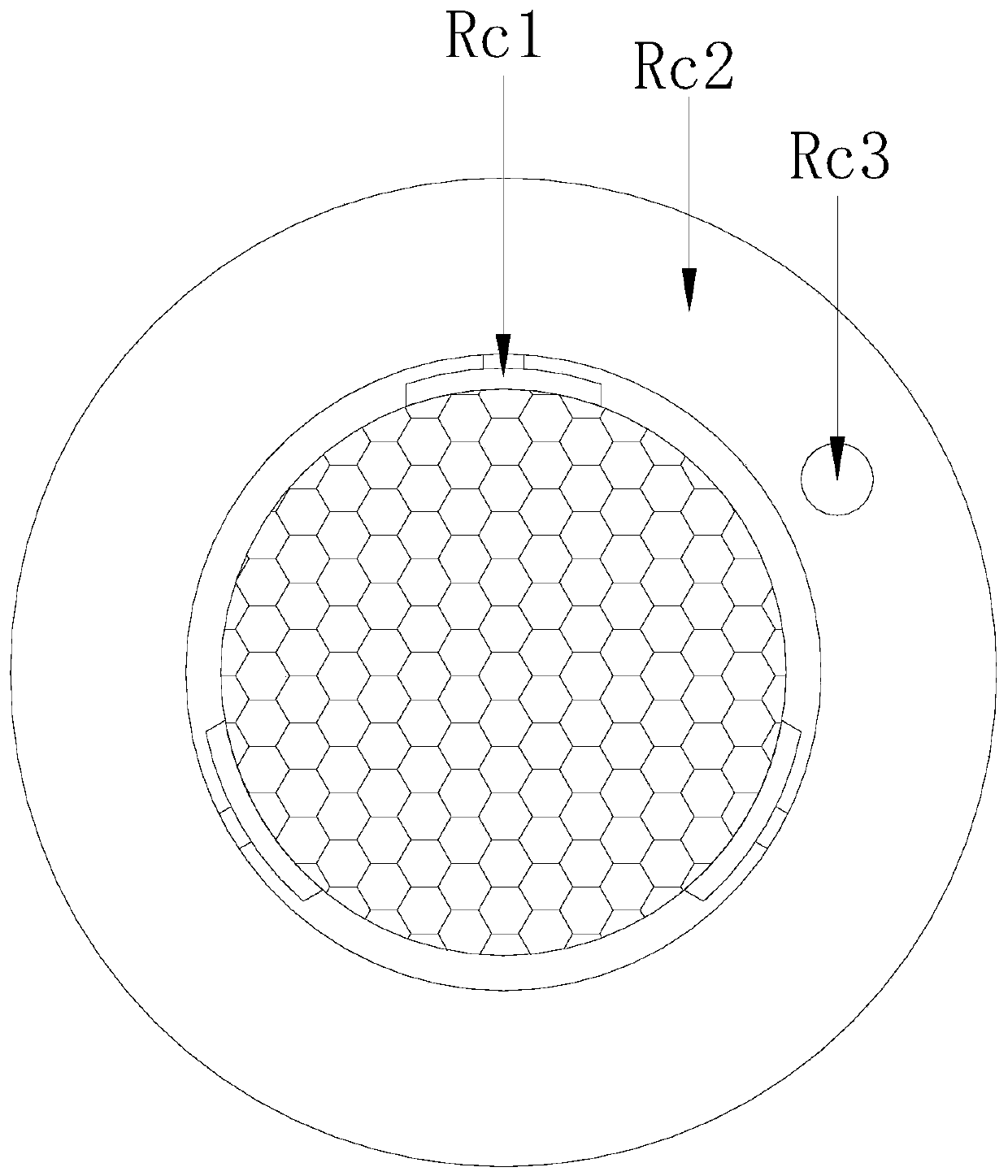

[0035] The conveyor belt 400 includes a belt body Ra, a mounting seat Rb, a ceramic holder Rc, and a support shaft Rd, and the belt body Ra is evenly distributed with ceramic holders Rc arranged equidistantly, and the ceramic holder Rc Both sides of both sides are movably connected with the mounting base Rb through the support shaft Rd, the mounti...

Embodiment 2

[0044] see Figure 1-9 , the present invention provides a technical solution of circular honeycomb ceramic automatic detection equipment: its structure includes a support frame 100, a detection device 200, a honeycomb ceramic 300, a conveyor belt 400, and a conveyor body 500, and the conveyor body 500 is equipped with There is a conveyor belt 400, and a honeycomb ceramic 300 is placed on the conveyor belt 400. A detection device 200 is arranged above the honeycomb ceramic 300. The detection device 200 is installed on a support frame 100, and the support frame 100 is connected to the conveyor body 500. make a mechanical connection;

[0045] The conveyor belt 400 includes a belt body Ra, a mounting seat Rb, a ceramic holder Rc, and a support shaft Rd, and the belt body Ra is evenly distributed with ceramic holders Rc arranged equidistantly, and the ceramic holder Rc Both sides of both sides are movably connected with the mounting base Rb through the support shaft Rd, the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com