Antibacterial heat-insulating master batch for PPR pipe, and preparation method thereof

A technology of masterbatch and antibacterial agent, which is applied in the field of antibacterial and heat insulation masterbatch and its preparation, can solve the problems of low production efficiency and single antibacterial function, and achieve the effect of excellent mechanical properties, excellent antibacterial and heat insulation dual functions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

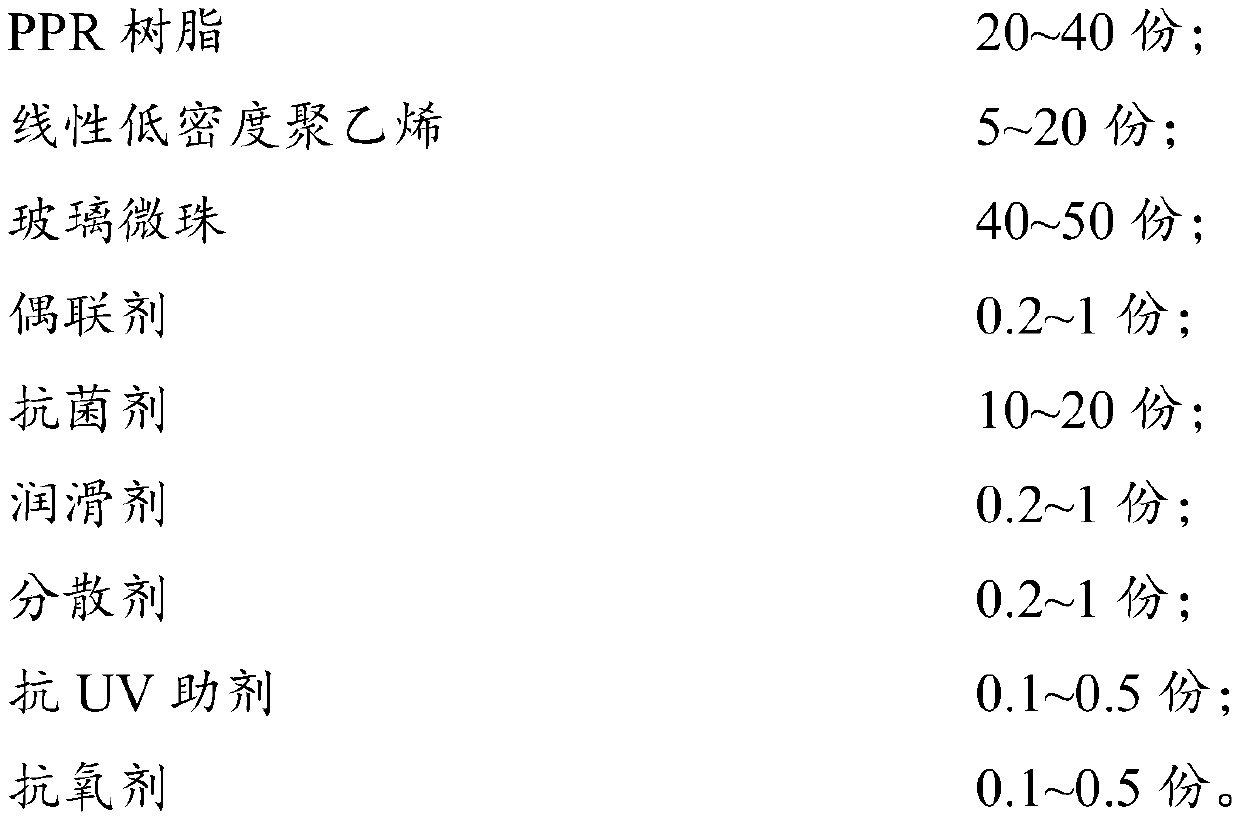

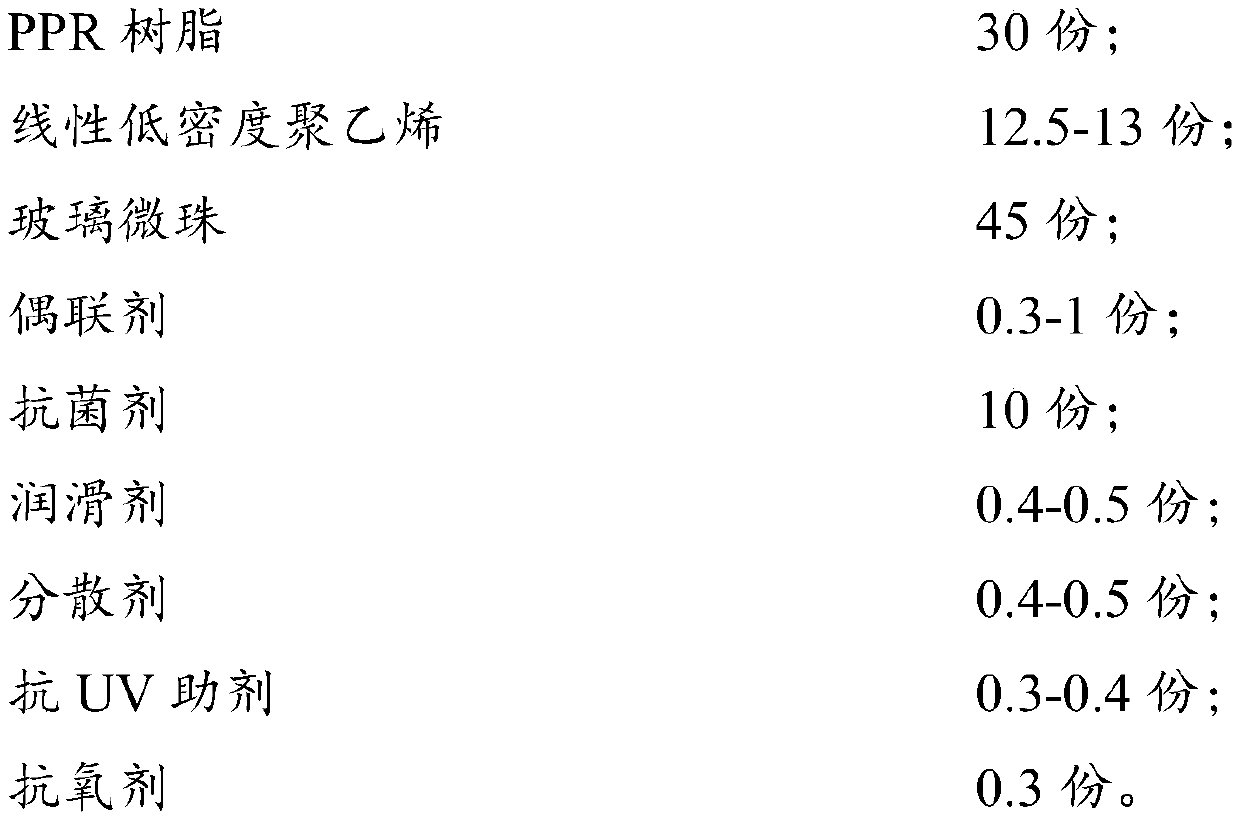

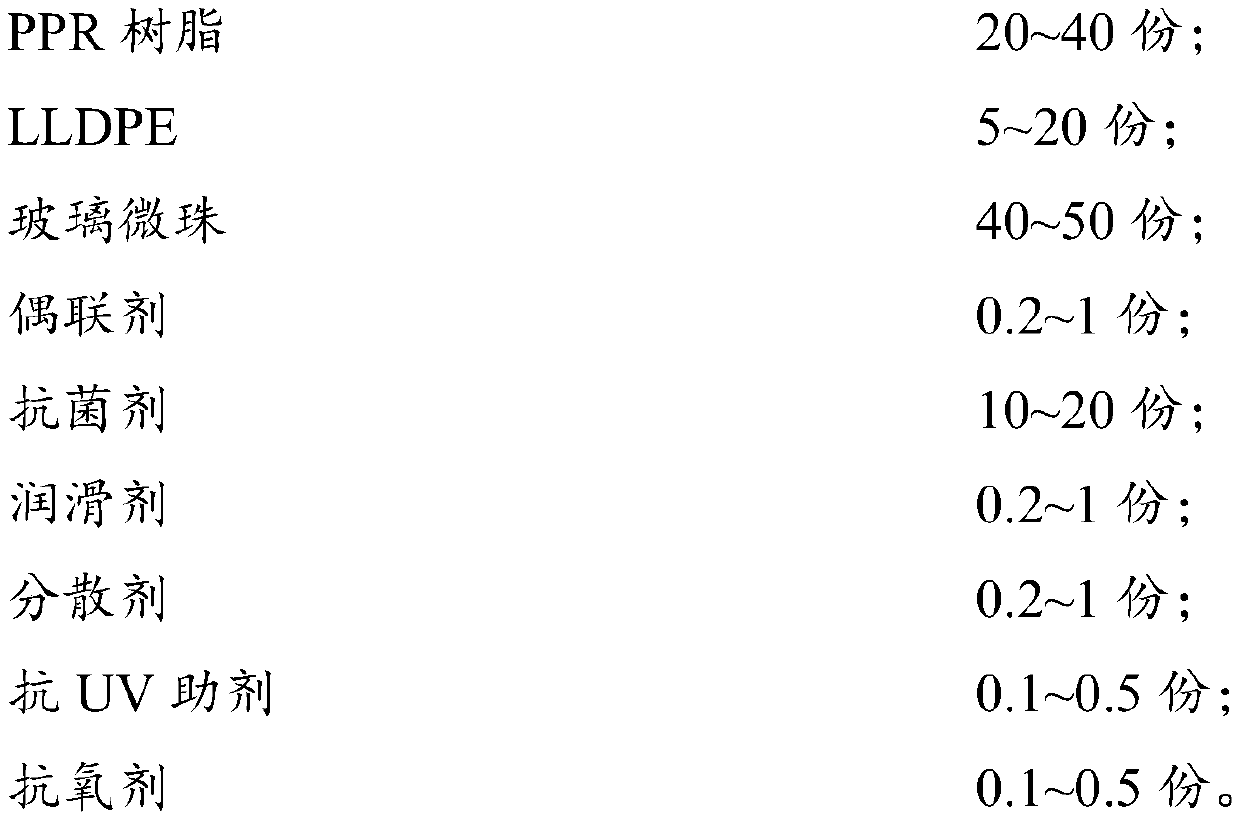

[0029] Examples 1-4 are all examples of the preparation method of the antibacterial and heat-insulating masterbatch for PPR pipes of the present invention. The ratio of the raw materials used in these preparation methods is shown in Table 1, and includes the following preparation steps:

[0030] (1) Put the glass beads and the coupling agent into the mixture and mix at low speed for 10 minutes to obtain surface activated glass beads;

[0031] (2) Put the antibacterial agent, dispersant, lubricant, LLDPE and the surface activated glass beads obtained in step (1) into the kneader for 20 minutes, and then crush to obtain crushed material;

[0032] (3) Put the antioxidant, anti-UV additives, PPR resin and the crushed material obtained in step (2) into the mixture and mix at low speed for 5 minutes, then add the twin screw extruder to extrude, cool, dry, and pellet , Packaging to obtain the masterbatch;

[0033] Among them, the particle size of the glass beads is 10-150μm, the coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com