Toughened aging-resistant polyolefin composition and preparation method thereof

A composition and polyolefin technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as poor interlayer adhesion, achieve low water absorption, and the preparation method is simple and easy, The effect of good patience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

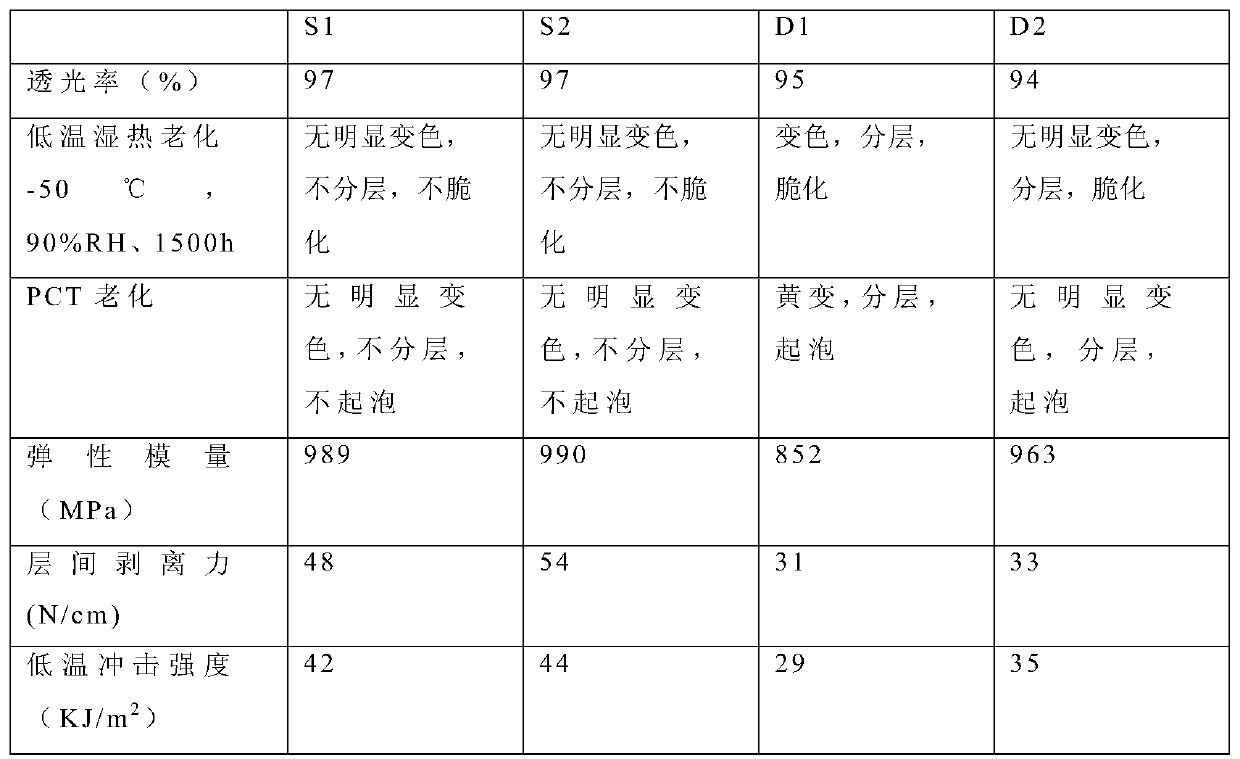

Examples

Embodiment 1

[0031] Component A: Weigh 70g homopolypropylene HP500N (China Sea Shell Petrochemical Co., Ltd.), 30g linear low-density polyethylene DFDC 7050 (Yangzi Petrochemical Company), 1g vinyltriethoxysilane A151 (Nanjing Youpu Chemical Co., Ltd. company), 2g HX-3; 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol nucleating agent 3988 (Beijia Fine Chemical Polymer Materials Co., Ltd.), 0.1g antioxidant 2,6-tertiary butyl-4-methylphenol (Beijing Institute of Addition Auxiliaries), 0.2g light stabilizer bis(2,2,6,6-tetramethyl-4- Piperidinyl) sebacate (Beijing Institute of Addition Auxiliaries).

[0032] Component B: Weigh 80g homopolypropylene, 20g linear low-density polyethylene DFDC 7050 (Yangzi Petrochemical Company), 1g vinyltriethoxysilane A151 (Nanjing Youpu Chemical Co., Ltd.), 0.3g ditert-tert peroxide Butyl (Aladdin), 3gHX-3; 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol nucleating agent 3988 (Beijia Fine Chemical Polymer Materials Co., Ltd. company), 0.05g antioxidant 2,6-...

Embodiment 2

[0035] Component A: Weigh 70g homopolypropylene HP500N (China Sea Shell Petrochemical Co., Ltd.), 30g linear low-density polyethylene DFDC 7050 (Yangzi Petrochemical Company), 1g vinyltriethoxysilane A151 (Nanjing Youpu Chemical Co., Ltd. company), 2g HX-3; 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol nucleating agent 3988 (Beijia Fine Chemical Polymer Materials Co., Ltd.), 0.1g antioxidant 2,6-tertiary butyl-4-methylphenol (Beijing Institute of Addition Auxiliaries), 0.2g light stabilizer bis(2,2,6,6-tetramethyl-4- Piperidinyl) sebacate (Beijing Institute of Addition Auxiliaries).

[0036]Component B: Weigh 80g homopolypropylene, 20g linear low-density polyethylene DFDC 7050 (Yangzi Petrochemical Company), 1g vinyltriethoxysilane A151 (Nanjing Youpu Chemical Co., Ltd.), 0.3g ditert-tert peroxide Butyl (Aladdin), 0.05g ditoluoyl peroxide (Shanghai Yiji Industrial Co., Ltd.), 3g HX-3; 1,3:2,4-di(3,4-dimethylbenzylidene) -D-sorbitol nucleating agent 3988 (Beijia Fine Chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap