Foundation pit roadbed backfilling structure

A technology for foundation pits and roadbeds, which is used in infrastructure engineering, underwater structures, roads, etc., can solve problems such as foundation pit collapse, and achieve the effects of increasing strength, increasing bearing resistance, and facilitating fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

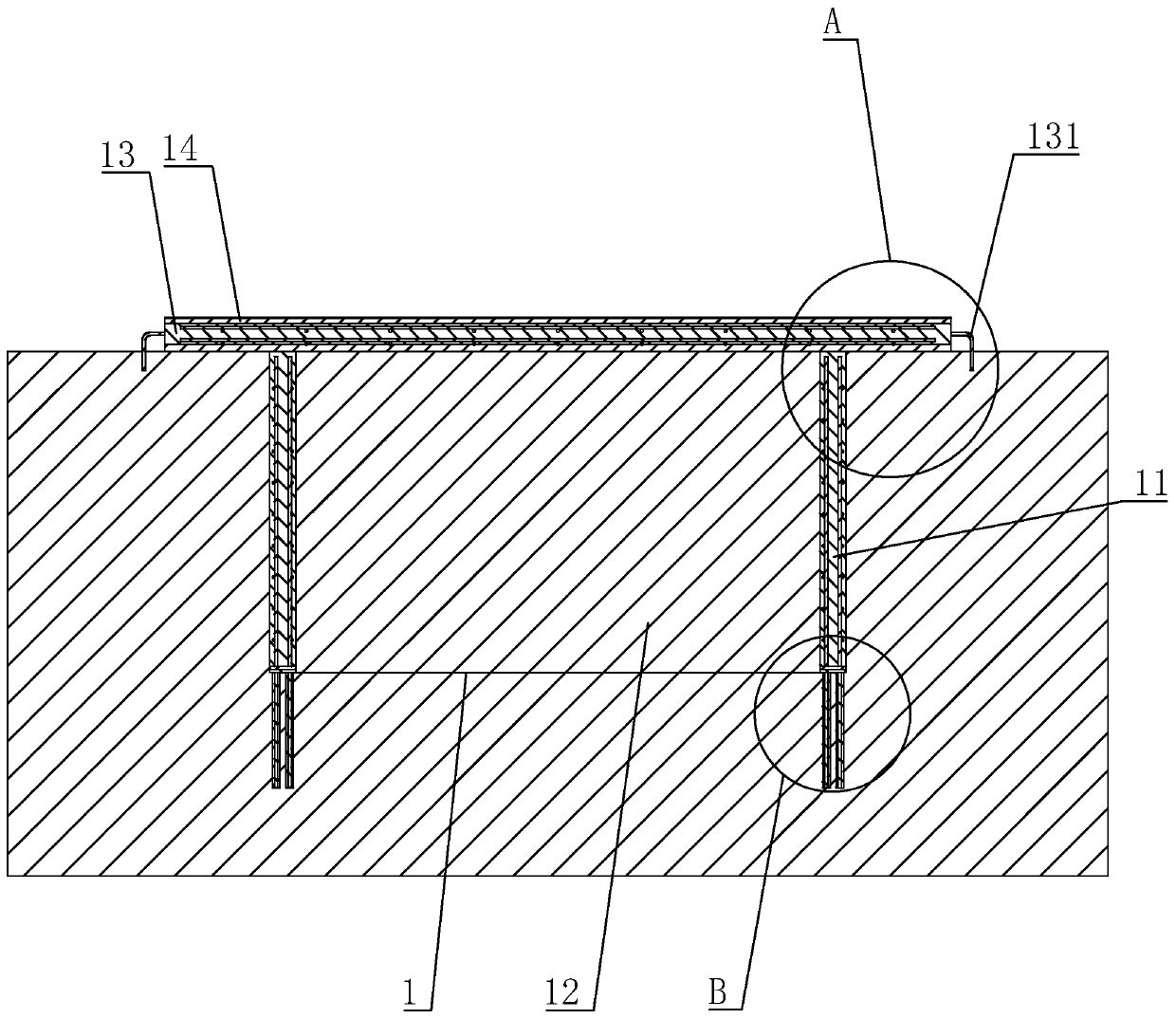

[0038] It is a foundation pit subgrade backfill structure disclosed by the present invention, such as figure 1 As shown, including the foundation pit 1, there is a concrete retaining wall 11 in the foundation pit 1 that is in conflict with each inner wall of the foundation pit 1, and the inner wall of the foundation pit 1 is reinforced, and the foundation pit 1 is filled with air bubble concrete 12, which is light in weight, Small bulk density, energy saving and environmental protection, can reduce the self-weight load on the existing underground structure roof or caps and other structures.

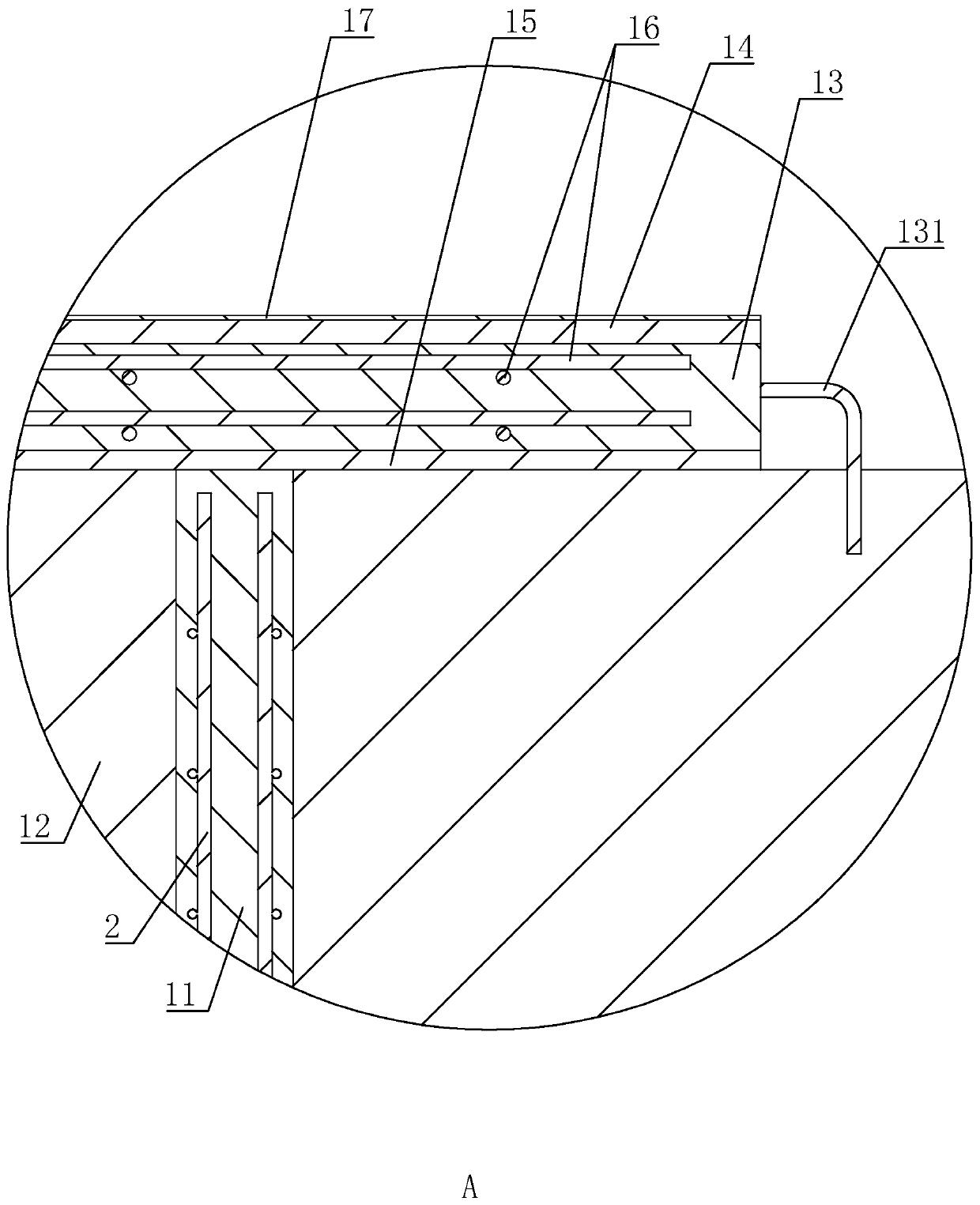

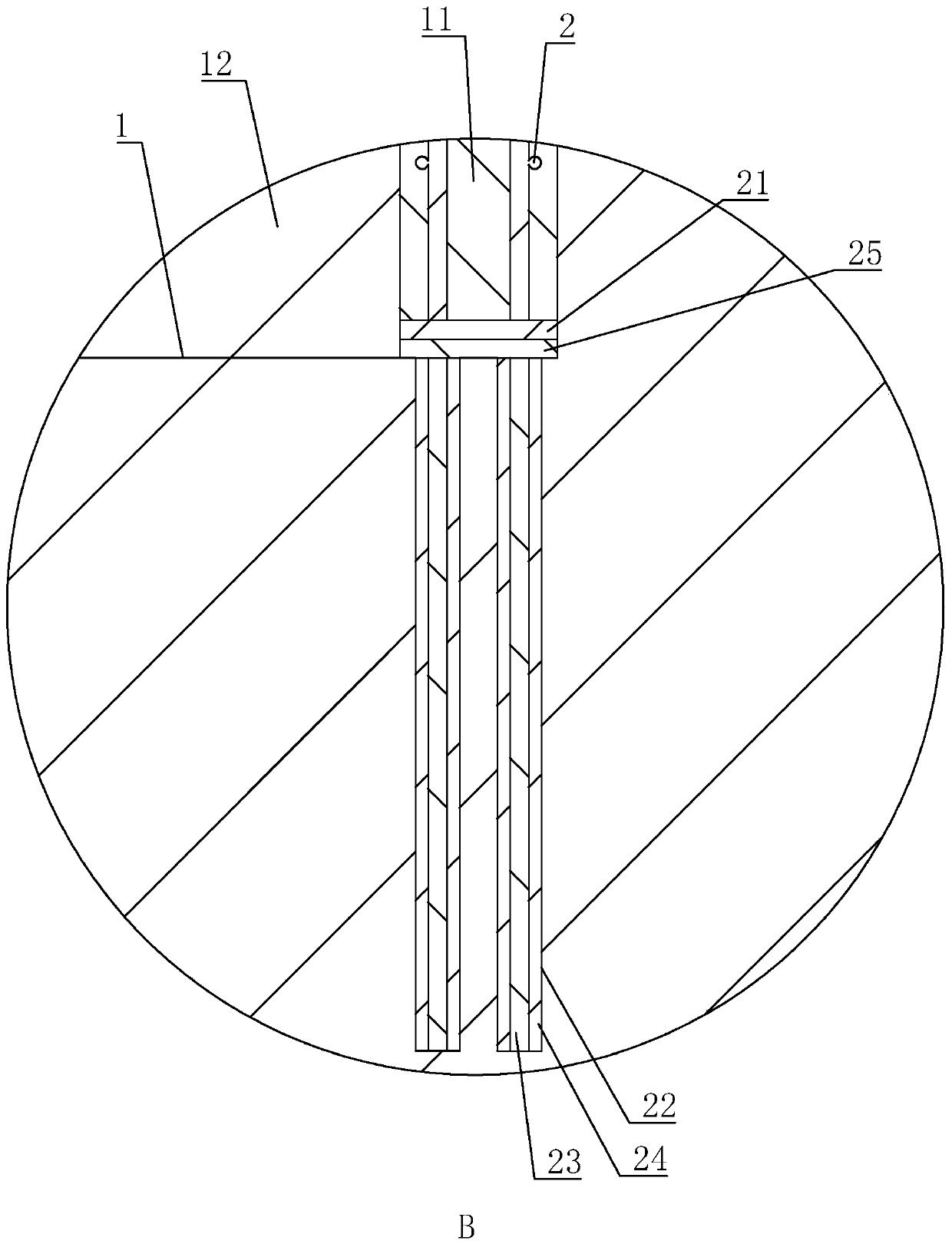

[0039] Such as figure 2 As shown, the cellular concrete 12 is paved with a steel-plastic geogrid 15, the length of the steel-plastic geogrid 15 is greater than the length of the foundation pit 1, and it embeds and locks the soil around the foundation pit 1, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com