Mold-free laminated column and construction method thereof

A technology of stacking columns and concrete, applied in the direction of columns, piers, pillars, etc., can solve the problems of consuming large forest resources, waste of resources, environmental hazards, etc., to achieve convenient and fast construction, enhance shear resistance, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following structures further describe the technical solutions in the embodiments of the present invention in combination with the drawings in the embodiments of the present invention.

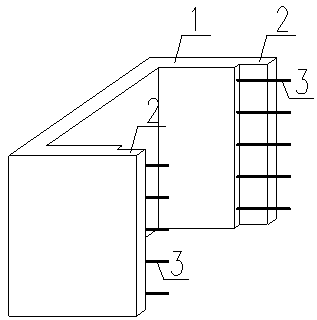

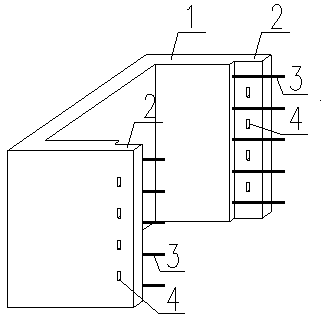

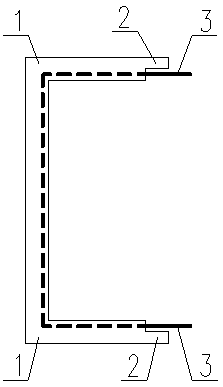

[0028] Such as Figure 1-14 As shown, a form-free composite column of the present invention includes a concrete prefabricated side wall, a steel cage 8, and cast-in-place concrete 9. The prefabricated side wall is filled with cast-in-place concrete 9, and the cast-in-place concrete 9 is provided with a reinforcement cage 8 connected with the concrete prefabricated side wall. The concrete prefabricated block layer is formed by joining together two concrete prefabricated blocks 1 .

[0029] refer to figure 1 — Figure 4 , both are concrete prefabricated blocks 1, where figure 1 — image 3 shows a semi-square block, Figure 4 A semi-circular block is shown; stirrups are pre-embedded in the prefabricated concrete block 1, the stirrups are provided with mustache tendons 3, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com