Cast-in-place pile reinforcement cage positioning operation table and application method thereof

A technology for steel cages and cast-in-place piles, applied in sheet pile walls, construction, infrastructure engineering, etc., can solve problems such as affecting the quality of pile foundations, low machining accuracy, and inability to guarantee the lap length of steel cages, so as to ensure the quality of production. , The quality of the finished product is good, and the effect of lap length guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

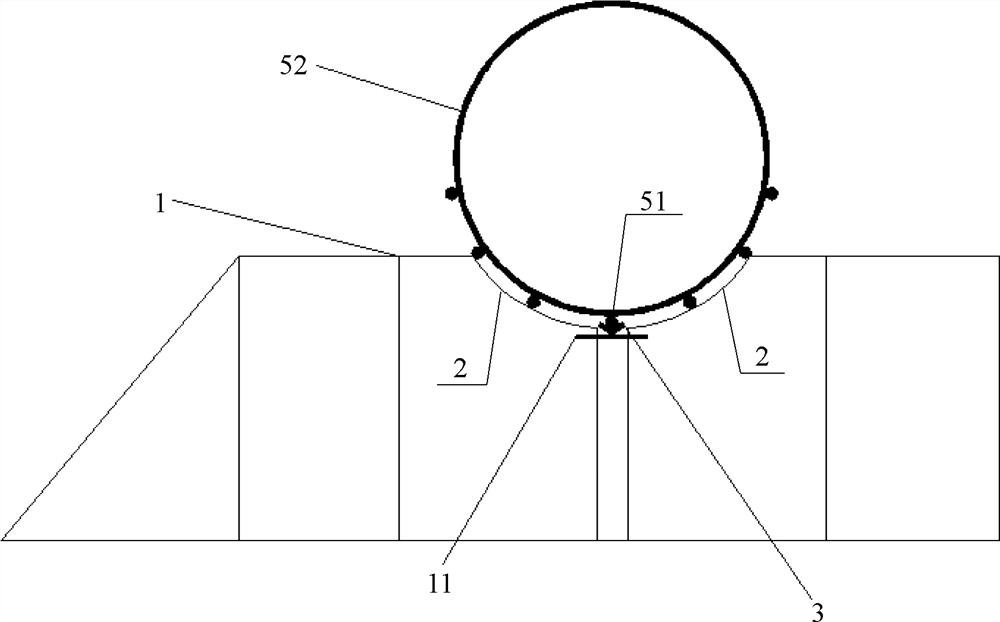

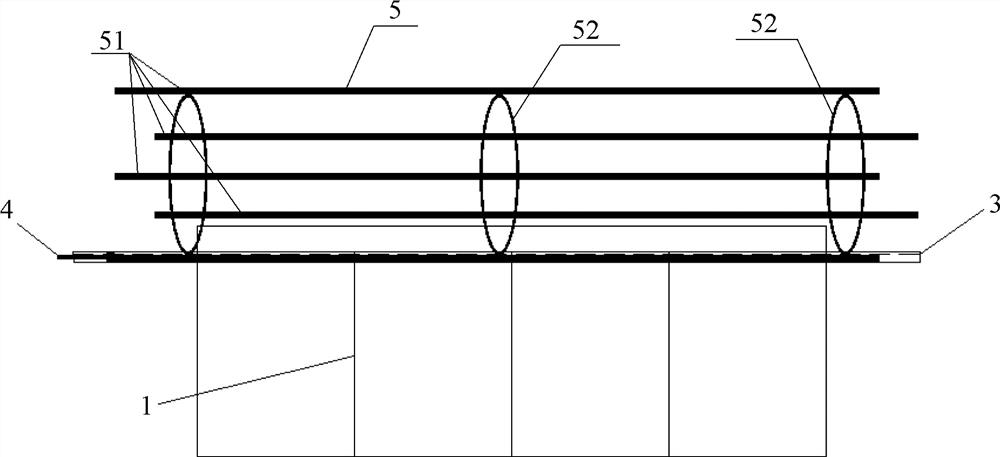

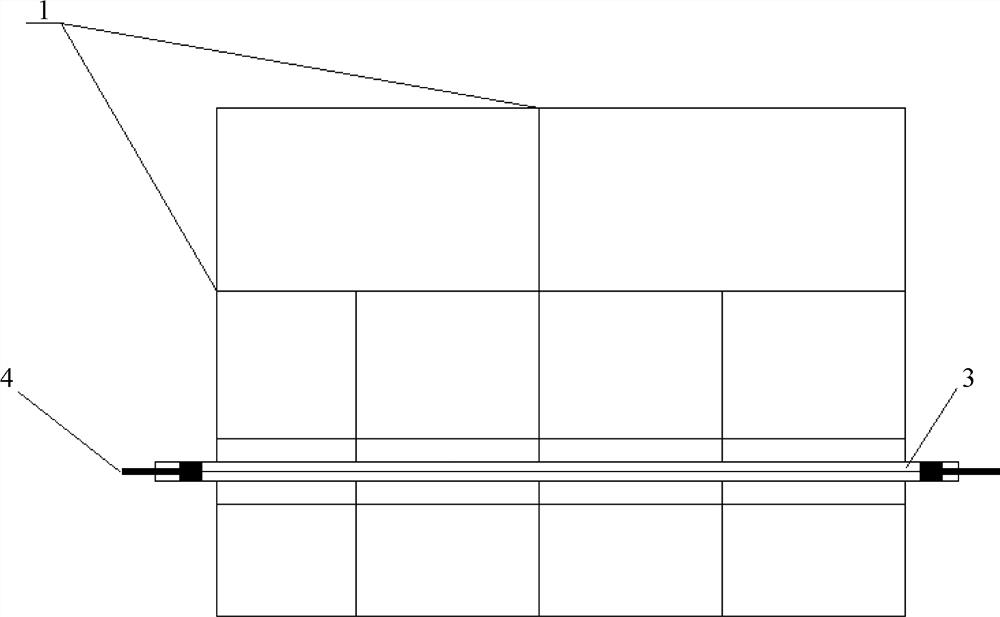

[0024] A positioning console for cast-in-place pile reinforcement cages, comprising a base 1, a cage positioning groove 2, a rib positioning groove 3 and a positioning ruler 4, such as Figure 1 ~ Figure 4 As shown, the specific structure is:

[0025] The middle part of base 1 is provided with cage locating groove 2, and the cross section of cage locating groove 2 is arc-shaped, and the lowest point of cage locating groove 2 is provided with rib locating groove 3, and positioning ruler 4 comprises triangular plate and scale ruler, and described scale One end of ruler is fixed on a right angle limit of described triangular plate.

[0026] In this embodiment: the base 1 is welded with steel bars, and the lower part of the base 1 is provided with a positioning rod 11; the cage positioning groove 2 is bent into an arc shape with at least three steel bars and then arranged parallel to each other and fixed at the middle and lowest point of the base 1 Disconnected structure, the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com