Pump type magnetorheological fluid retarder

A magnetorheological fluid and retarder technology, which is applied to hydraulic resistance brakes, brake types, mechanical equipment, etc., can solve the problems of limited torque size, limited braking force, and complex structure of stator and rotor hydraulic retarders. Achieve the effect of reducing the frequency of use, low power consumption, and excellent controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

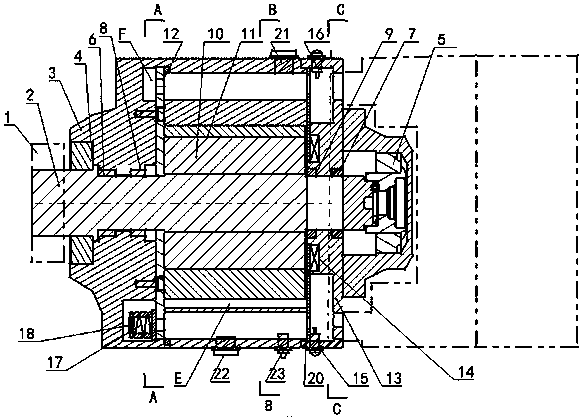

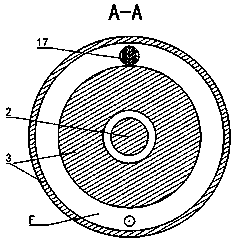

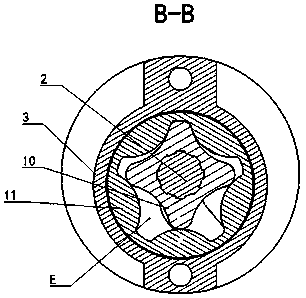

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The first embodiment of the present invention is an inner meshing cycloidal rotor pump magneto-rheological fluid retarder; figure 1 , figure 2 , image 3 , Figure 4As shown, the parallel arrangement has an input gear and is connected to the retarder shaft through a spline in a torque-proof manner; including input gear 1, retarder shaft 2, retarder body 3, front bearing 4, rear bearing 5 at the right end of the shaft, Outer oil seal 6, outer oil seal 7, inner oil seal 8, inner oil seal 9, pump, steel plate 12, right end cover 13, working magnetic coil 14, inlet temperature sensor 15, outlet temperature sensor 16, excitation coil 17, steel plate 18, 20 silicon steel plate , 21 refueling screw plug, 22 oil draining screw plug, 23 exhaust check valve, E working chamber, F high and low pressure area channel; there are inner rotor 10 and eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com