Boiler ash removal system

A technology for ash removal and boiler application in the fields of removal of solid residues, treatment of combustion products, and combustion methods. It can solve problems such as unstable operating conditions, increased heat transfer resistance, and impact on production quality, so as to improve work efficiency. And, reduce the probability of failure, the effect of significant cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

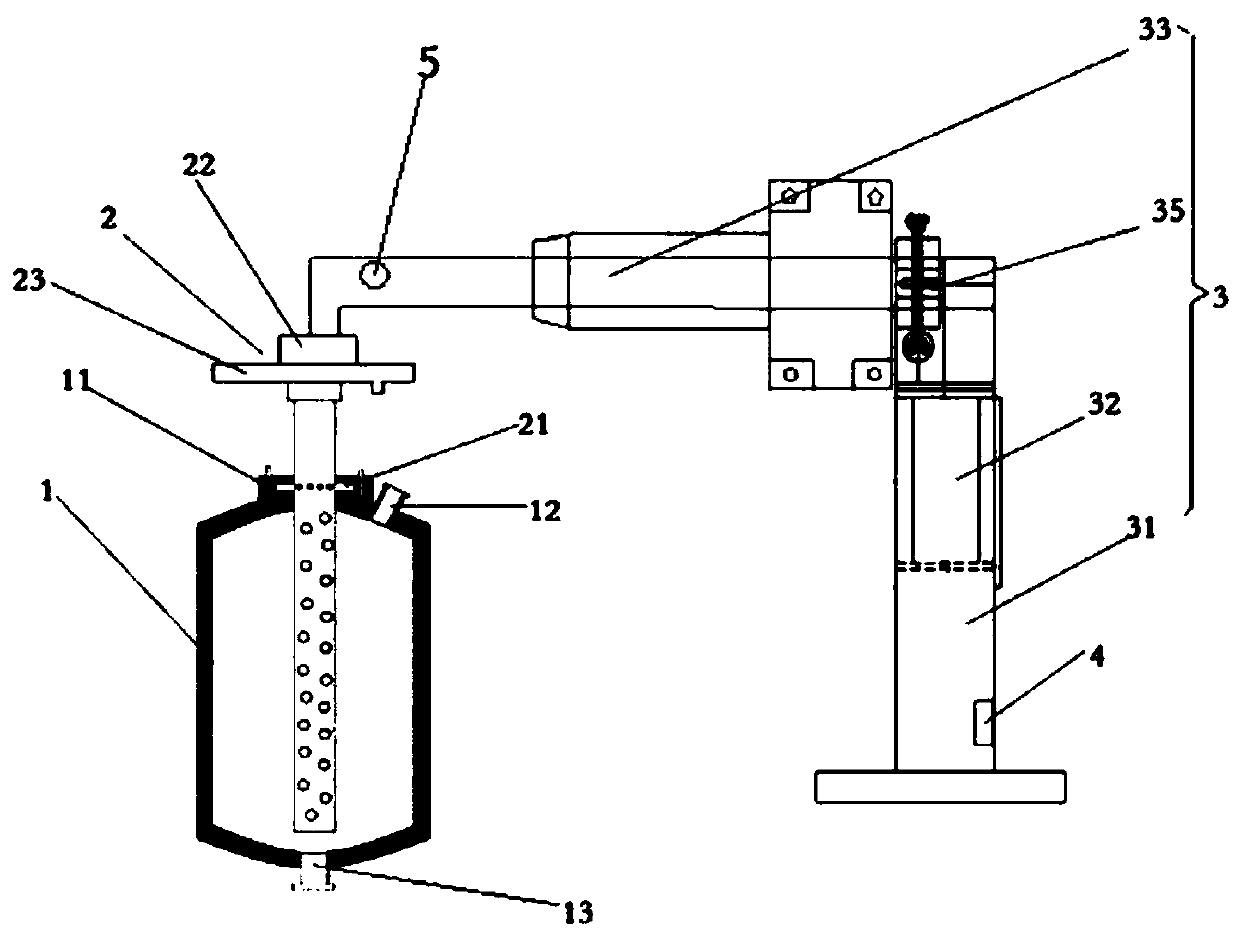

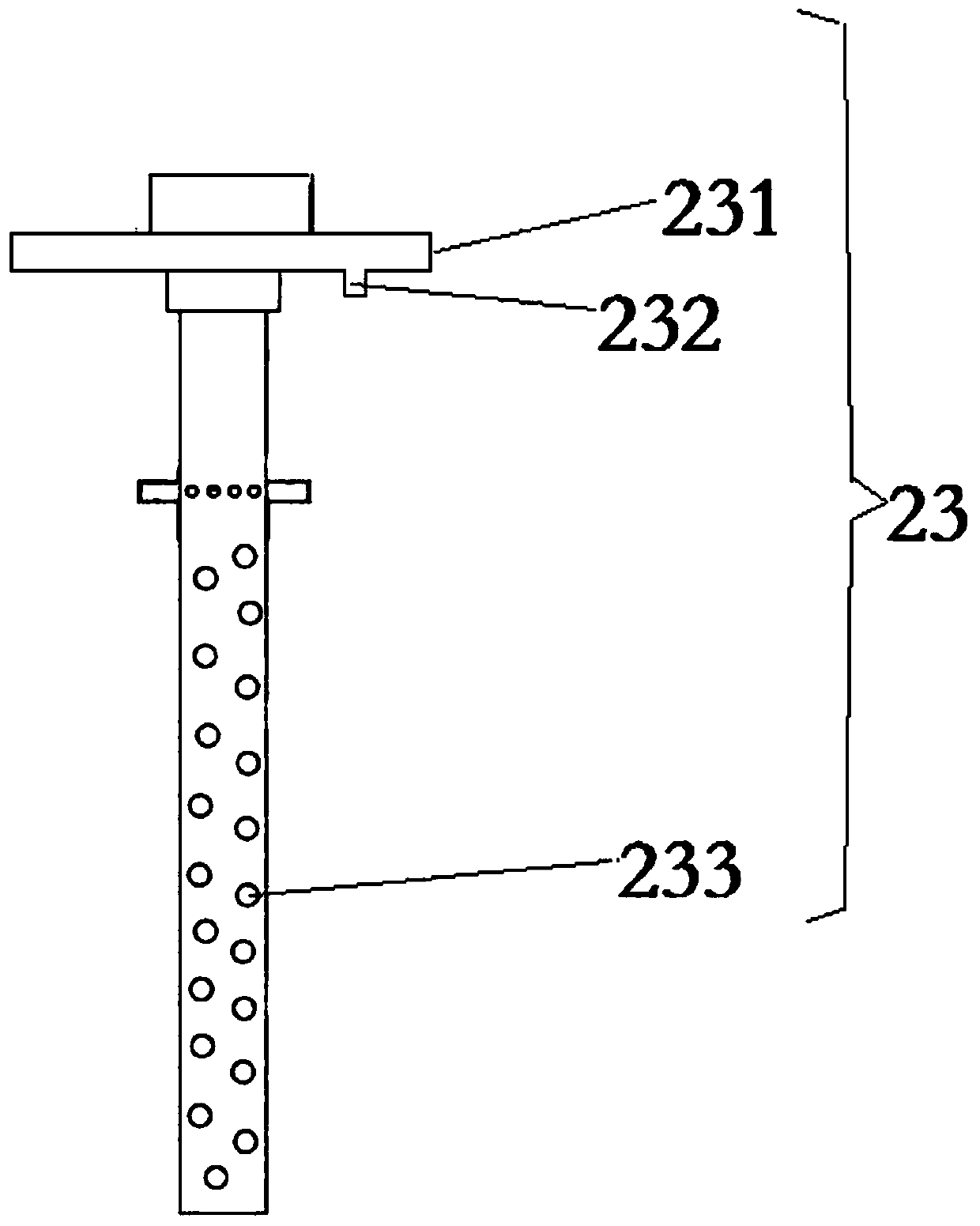

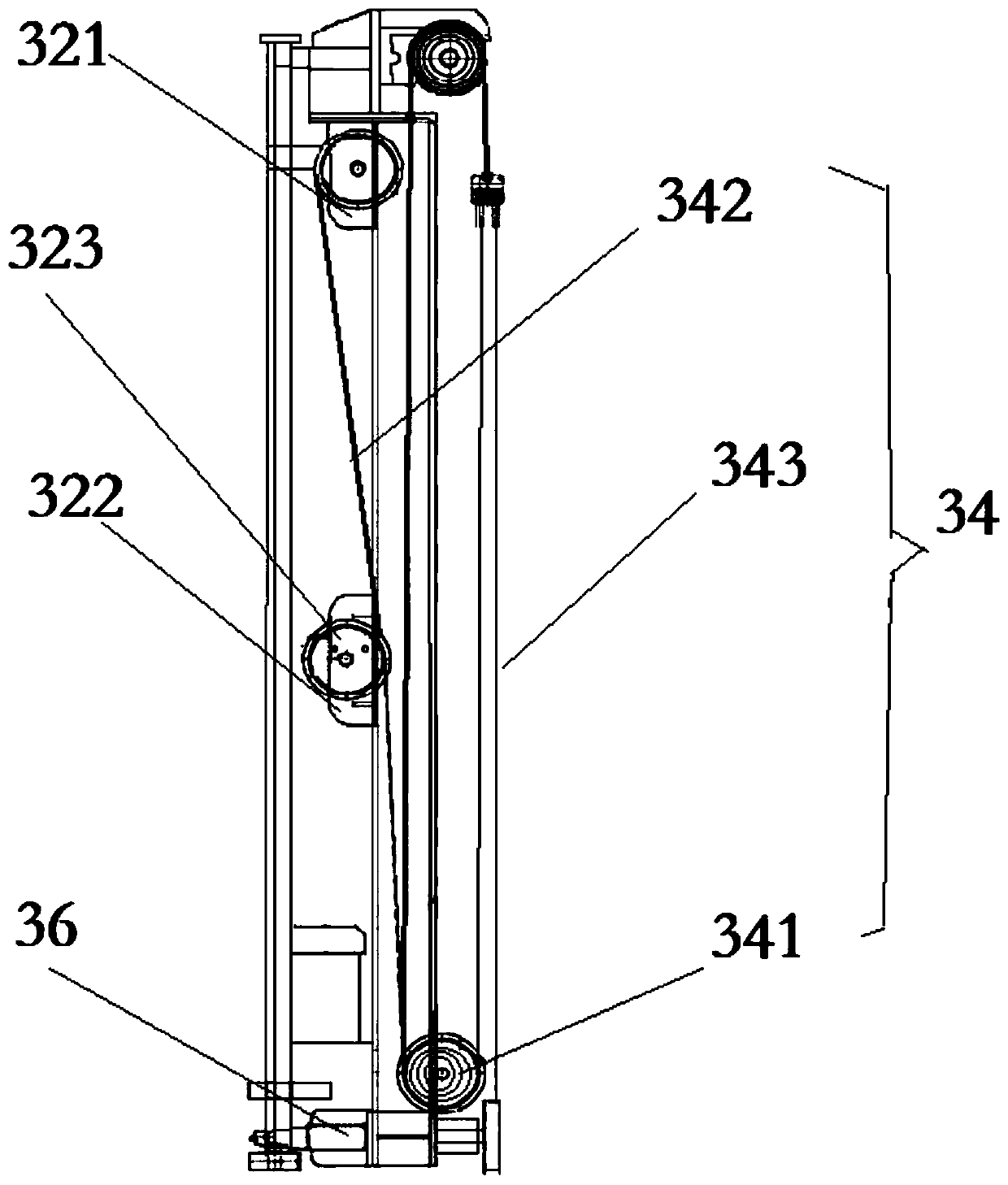

[0033] Such as Figure 1-5As shown, the present invention provides a boiler dust removal system, and the boiler is a boiler used in aluminum alloy processing. In this embodiment, the boiler dust removal system includes a boiler body, a dust removal device, a transmission device, a control device and terminal, and the soot removal device on the boiler body is clamped; the transmission device is fixedly connected to the soot removal device for moving the ash removal device; the control device is connected to the ash removal device And the transmission device is electrically connected, the control device includes a central controller, the central controller includes an input control module and an execution module, the input control module is used to receive the control instructions of the terminal, and the execution module is used to generate The execution action corresponding to the control instruction of the input control module; the terminal is connected to the control device ...

Embodiment 2

[0039] Such as Figure 1-5 As shown, the present invention provides a boiler dust removal system, the boiler dust removal system is used for aluminum alloy processing boilers, the boiler dust removal system includes a boiler body, a dust removal device, a transmission device, a control device and a terminal, and The soot cleaning device on the boiler body is clamped. Specifically, in this embodiment, the boiler body is provided with a first clamping block, and the soot cleaning device is provided with a second clamping block. The first clamping block and the second clamping block can form a clamping connection, and the clamping adopts a concave-convex matching structure. In this embodiment, the first clamping block is designed as a groove, and the second clamping block The clamping block is designed as a protrusion, and the protrusion can cooperate with the groove to form a clamping connection, and the groove is provided with a control valve. When the dust cleaning work of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com