Gradient zero-Poisson-ratio structure capacitive flexible tactile sensor and preparation method thereof

A technology of tactile sensor and structural capacitance, which is applied in the fields of instruments, manufacturing, measuring devices, etc., can solve the problems of not realizing multi-material integrated manufacturing of sensors, simple structure, and inability to achieve high flexibility, high sensitivity and high detection limit at the same time. , to achieve the effect of eliminating deformation coupling, preventing agglomeration and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

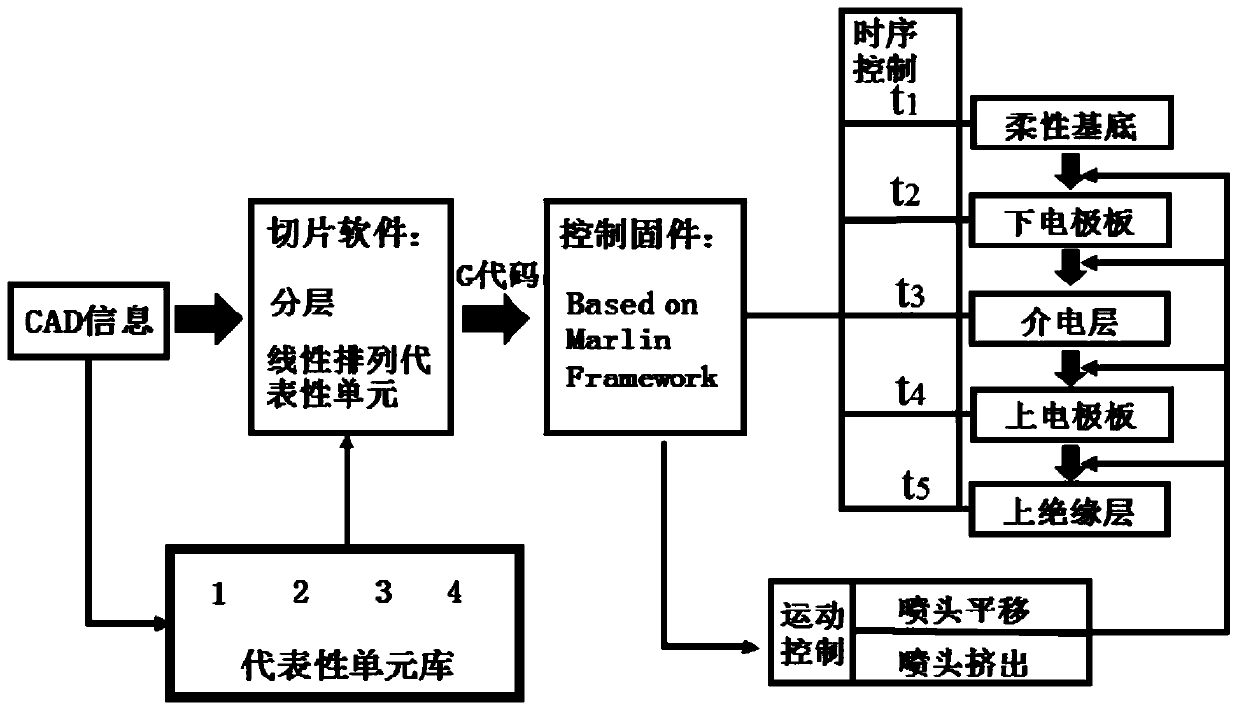

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

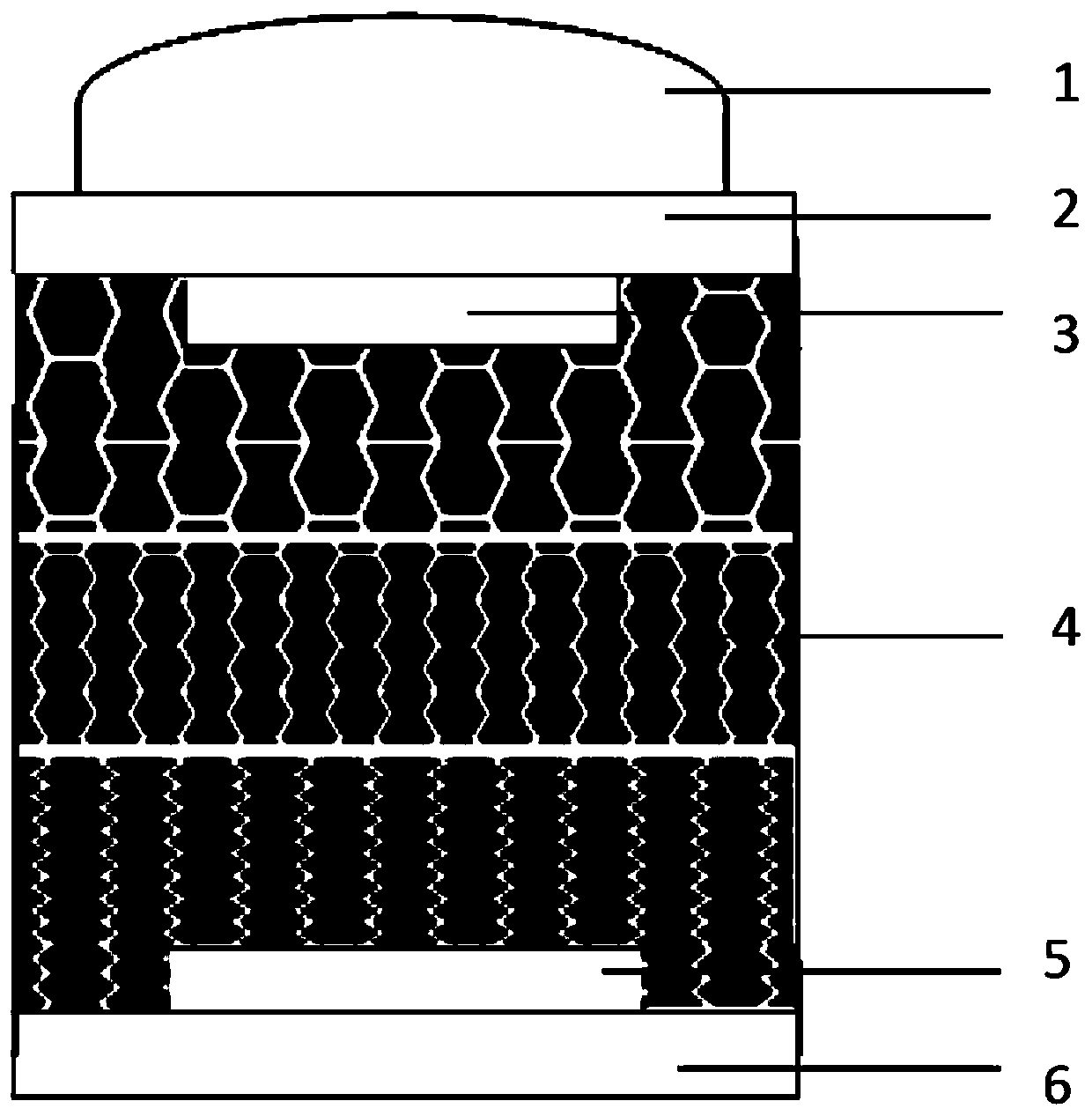

[0028] A capacitive flexible tactile sensor with gradient zero Poisson's ratio structure, the capacitive flexible tactile sensor comprises insulating surface protrusions, an insulating film, flexible electrodes, a dielectric layer and a substrate film.

[0029] Further, the insulating surface protrusion is located on the uppermost layer of the capacitive flexible tactile pressure sensor, is a circular arc protrusion made of PDMS material, and is a contact area between the capacitive flexible tactile pressure sensor and an external object.

[0030] Further, the insulating film is a flexible film made of PDMS material, and is located on the lower layer of the insulating protrusion.

[0031] Further, the dielectric layer is conductive airgel of PDMS / CNFs / Graphene composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com