Shiftable large-range capacitive coupling type non-contact conductivity measuring device and method

A non-contact conductance, measuring device technology, applied in the direction of material resistance, etc., can solve the problems of inconvenient application of multi-channel conductance detection, frequency selection limitation, difficulty in resonance adjustment, etc., and achieves small measurement requirements, high sensitivity, convenient and applicable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

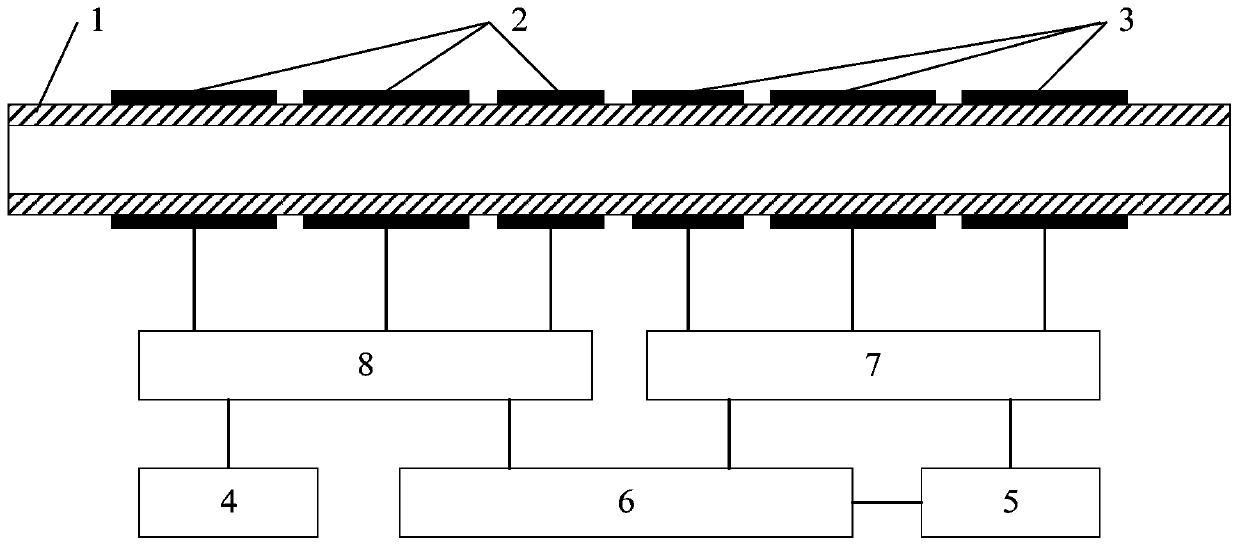

[0036] Such as figure 1As shown, this embodiment provides a capacitively coupled non-contact conductivity measurement device with a wide range of shiftable gears, including an insulating measurement pipeline 1, an excitation electrode module 2, a receiving electrode module 3, an AC excitation source 4, and a voltage detection module 5 , a control unit 6, a receiving electrode analog switch 7 and an excitation electrode analog switch 8. The excitation electrode module 2 is installed at one end of the insulated measurement pipeline 1 , and the receiving electrode module 3 is installed at the other end of the insulated measurement pipeline 1 . The common end of the excitation electrode analog switch 8 is connected to the AC excitation source 4; the channel end of the excitation electrode analog switch 8 is connected to the excitation electrode module 2 installed on the outer wall of the insulating measurement pipeline 1; the channel end of the receiving electrode analog switch 7 ...

Embodiment 2

[0056] The basic structure and principle of this embodiment are the same as those of the first embodiment, the difference is that the excitation electrode module 2 has only one excitation electrode, and the reception electrode module 3 uses three reception electrodes. The receiving electrode is arranged on one side of the exciting electrode, forming a semi-nested electrode arrangement. Only one receiving electrode is in the working state at any time, and the control unit 6 controls the receiving electrode analog switch 7 to switch on different receiving electrodes to realize gear switching. The receiving electrode and the excitation electrode of the electrode form a higher gear, and the number of receiving electrodes is the number of gears. The length of each receiving electrode in the electrode module is the same, and is also the same as that of the excitation electrode.

[0057] The measurement process of this embodiment is:

[0058] Before measurement: measure each electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com