Identification system for V-CUT of circuit board

A V-CUT and identification system technology, applied in printed circuit testing, electronic circuit testing, etc., can solve the problems of manual inspection and easy missed inspection, and achieve the effect of improving yield rate, avoiding missed inspection, and improving inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

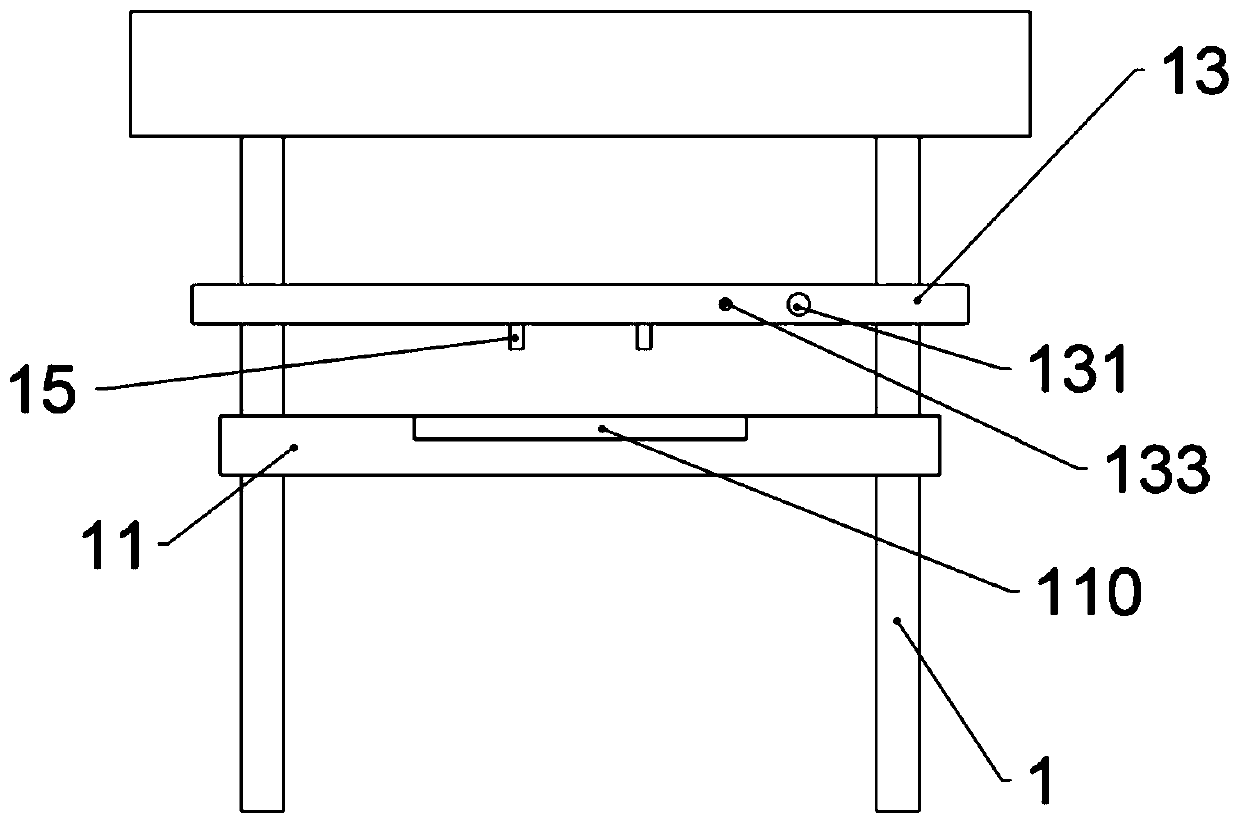

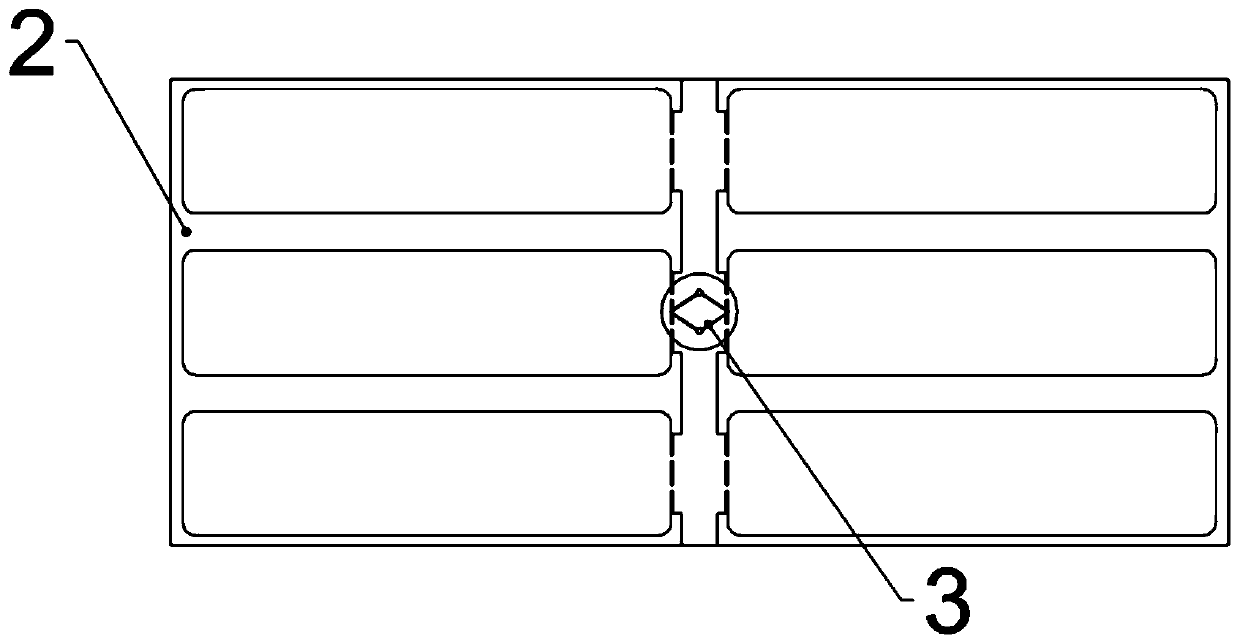

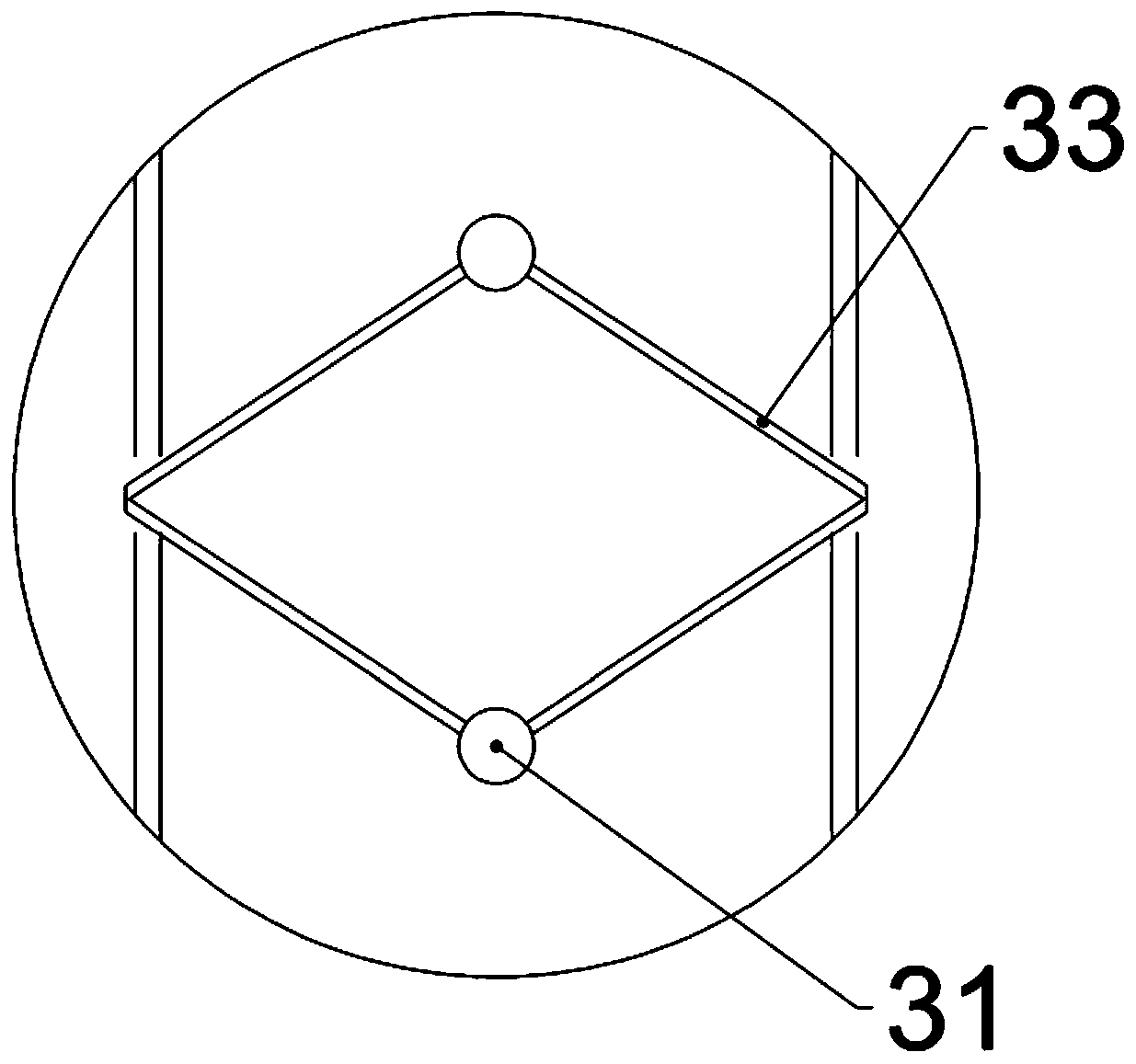

[0025] Basic as attached figure 1 Shown: the identification system for circuit board 2V-CUT, including a marking module, used to mark the circuit board 2 with the test wire 3, the test wire 3 includes a test line 33 and test points 31 at both ends of the test line 33, The test lead 3 passes through the preset V-CUT position;

[0026] Detection mechanism, including detection circuit, driver board 13, placement board 11 and indicator light, such as figure 1 As shown, the drive plate 13 and the placement plate 11 are installed on the frame 1, the placement plate 11 is fixedly arranged on the frame 1, the drive plate 13 slides with the frame 1, and an elastic member is arranged between the drive plate 13 and the placement plate 11 , the upper end of the elastic member is connected to the lower surface of the drive plate 13, and the lower end of the elastic member is connected to the upper surface of the placement plate 11. Specifically, the elastic member can be a compression spr...

Embodiment 2

[0041] The difference from Embodiment 1 is that a collection mechanism is also provided in this solution. The collection mechanism is located on one side of the placement plate 11 . The collection mechanism includes a collection box, and one side of the collection box is against the placement plate 11 .

[0042] A collection mechanism is provided to collect the circuit boards 2 that have passed the test. After the placement board 11 is offset against the collection box, after the circuit board 2 passes the test, the circuit board 2 can be directly pushed into the collection box. The operation is simple.

Embodiment 3

[0044] Considering that when the PCB boards are placed, they are usually stacked in the warehouse in the form of full boxes. When necessary, the full boxes of PCB boards are taken out from the warehouse and then processed. Since the PCB boards are stored in a stacked manner, it is not standardized. The picking behavior makes the stability of the PCB board stacking weakened, subject to slight vibration, the PCB board is prone to drop, and the PCB board is prone to damage.

[0045] The difference between this embodiment and the first and second embodiments is that it also includes a supervision subsystem, an identity verification terminal and multiple monitoring terminals. The identity verification terminal is set at the gate of the warehouse, and the warehouse managers need to pass the verification before they can open the warehouse to pick up the goods. The monitoring terminals are installed in the warehouse, and are respectively installed in multiple positions of the warehous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com